3D Printing In Low-Cost Satellite Market Size 2024-2028

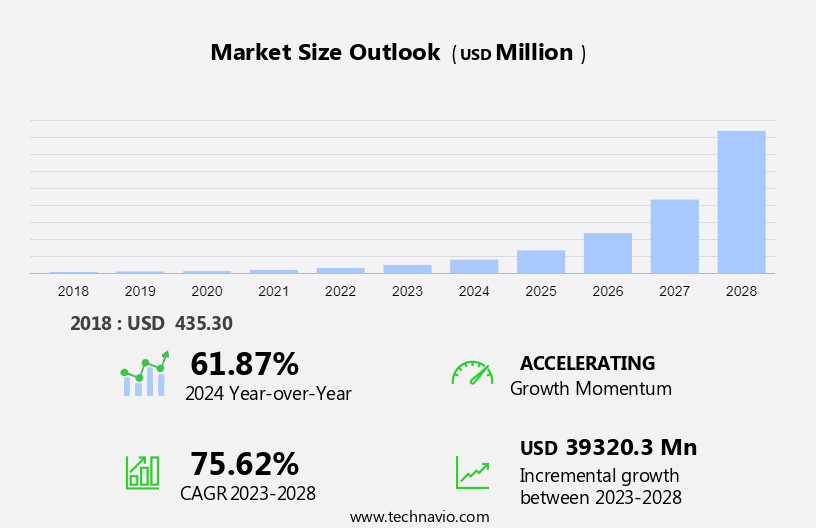

The 3D printing in low-cost satellite market size is forecast to increase by USD 39.32 billion at a CAGR of 75.62% between 2023 and 2028.

- The market is experiencing significant growth due to several key trends. The rapid development and deployment of affordable satellites have gained momentum, driven by the increasing number of space exploration missions. This trend is expected to continue as the scalability issues associated with 3D printing in low-cost satellite manufacturing are being addressed. 3D printing in low-cost satellites is revolutionizing space technology by utilizing additive manufacturing to create lightweight, cost-effective components, including solar panels that enhance satellite efficiency and sustainability. The potential for reducing production time and costs, as well as improving customization and design flexibility, make 3D printing an attractive option for satellite manufacturers. However, challenges remain, including the need for standardization and the development of reliable and high-performance 3D printing materials for space applications.

What will be the Size of the 3D Printing In Low-Cost Satellite Market During the Forecast Period?

- The 3D printing market in satellite manufacturing has gained significant traction in recent years due to its potential to revolutionize the space industry. This innovative technology enables the production of lightweight, customizable satellite components, reducing costs and increasing efficiency. Applications of 3D printing in satellite manufacturing span across various sectors, including communication, earth observation, navigation, internet access, telecommunications, broadcasting services, and military operations.

- Advanced 3D printer technology, coupled with the availability of specialized materials and printing techniques, is driving the growth of this market. Material suppliers are continuously developing new, high-performance materials suitable for space applications, further expanding the scope of 3D printing in satellite manufacturing. The integration of 3D printing technology in satellite constellations is expected to lead to mass production and faster deployment of satellites, making satellite-based services more accessible and affordable.

How is this 3D Printing In Low-Cost Satellite Industry segmented and which is the largest segment?

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Aerospace and defense

- Scientific research

- Product

- Power system

- Framework

- Antenna

- Geography

- North America

- US

- Europe

- Germany

- UK

- APAC

- China

- Japan

- South America

- Middle East and Africa

- North America

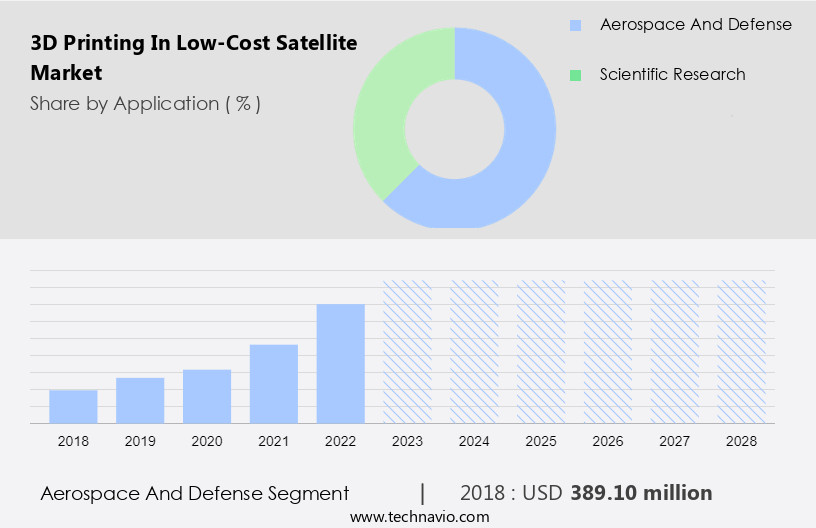

By Application Insights

- The aerospace and defense segment is estimated to witness significant growth during the forecast period.

The market is experiencing significant growth due to the increasing demand for affordable and efficient satellite technology in various industries, particularly In the aerospace and defense sectors. Small satellites, including Nano and Microsatellites, offer numerous advantages over traditional larger satellites, such as reduced manufacturing and launch costs, faster deployment times, and the ability to provide satellite-based services for communication, Earth observation, navigation, internet access, telecommunications, broadcasting services, military operations, and more.

3D printing technology is revolutionizing satellite manufacturing by enabling the production of lightweight and cost-effective satellite components, including antennas, brackets, shields, housings, propulsion systems, and more. This technology also allows for waste reduction and faster production times, making it an ideal solution for satellite production under budget constraints. The space industry is embracing advanced 3D printing technology to produce satellite constellations, with satellite manufacturers and space agencies collaborating to develop and implement this technology.

Get a glance at the 3D Printing In Low-Cost Satellite Industry report of share of various segments Request Free Sample

The aerospace and defense segment was valued at USD 389.10 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

- North America is estimated to contribute 47% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The United States and Canada are major contributors to the global demand for low-cost satellite services in North America. Government agencies, including NASA and private companies, are leading the development of new satellite systems to address the increasing need for satellites in areas such as navigation, communication, Earth observation, and military operations. The US civilian space sector, managed by NASA, focuses on aeronautics research, exploration systems, science, and space operations. In the US, the commercial sector's demand for low-cost satellites, particularly for communication, navigation, and Earth observation applications, is on the rise. Advanced 3D printing technology is revolutionizing satellite manufacturing by reducing waste, and enabling the production of complex satellite components such as antennas, brackets, shields, housings, propulsion systems, and satellite structures using Nano and Microsatellites and Small Satellites.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of 3D Printing In Low-Cost Satellite Industry?

Rapid development and deployment of low-cost satellites is the key driver of the market.

- The satellite industry is experiencing a significant shift towards small satellite missions, driven by advancements in satellite manufacturing using 3D printing technology. This innovation is enabling the production of satellite components such as antennas, brackets, shields, housings, propulsion systems, and more, using 3D printers and their printer technology. Material suppliers are also developing new, lightweight, and durable materials for 3D printing, further reducing the overall cost and weight of satellites. NASA and other space agencies, along with satellite manufacturers, are exploring the use of 3D printing for satellite production to meet budget constraints. The adoption of 3D printing in satellite manufacturing will lead to waste reduction and faster turnaround times.

- Furthermore, the use in space exploration will enable the production of advanced printing technology on-site, reducing the need for extensive supply chains. The growing demand for satellite-based services such as communication, Earth observation, navigation, internet access, telecommunications, and broadcasting services is fueling the growth of the satellite industry. The use of nano and microsatellites in constellations will provide cost-effective solutions for these services, making them accessible to a wider audience. Military operations also rely heavily on satellite technology for intelligence, surveillance, and reconnaissance. The integration in satellite manufacturing will enable the production of customized and lightweight satellite components, enhancing the capabilities of military operations.

What are the market trends shaping the 3D Printing In Low-Cost Satellite Industry?

An increasing number of space exploration missions is the upcoming market trend.

- The market is witnessing significant advancements in satellite manufacturing through the adoption of technology for space applications. In 2023, several space missions were launched with 3D-printed components, including antennas, brackets, shields, housings, propulsion systems, and more. These components were produced using advanced printing techniques and materials from various material suppliers.

- The space industry, including satellite production by manufacturers and satellite missions by space agencies, is facing budget constraints, making it an attractive solution for waste reduction. The technology is revolutionizing satellite manufacturing, enabling the production of Nano and Microsatellites and Small Satellites. This technology is being utilized for communication, Earth observation, navigation, internet access, telecommunications, broadcasting services, military operations, and more.

What challenges does the 3D Printing In Low-Cost Satellite Industry face during its growth?

Scalability issues associated with 3D printing in low-cost satellite manufacturing is a key challenge affecting the industry growth.

- The integration of technology in small satellite manufacturing holds significant potential for the space industry, enabling the production of satellite components with intricate designs at reduced costs. However, scalability poses a challenge in this domain. 3D printing's limitations in producing large and complex components at high volumes within a short timeframe hinder its widespread adoption in large-scale satellite production. Additionally, the use of specific materials essential for low-cost satellite manufacturing, such as tough, lightweight, and durable materials, may not be universally compatible with all techniques and equipment. These material constraints further complicate the scalability in satellite manufacturing.

- Despite these challenges, the advancement of technology and the increasing demand for satellite-based services, including communication, Earth observation, navigation, internet access, telecommunications, broadcasting services, military operations, and satellite constellations, continue to drive innovation in this field. Collaborative efforts between satellite manufacturers, space agencies, material suppliers, and 3D printer technology providers are crucial to overcoming these challenges and unlocking the full potential in low-cost satellite manufacturing.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, 3d printing in low-cost satellite market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Airbus SE

- EOS GmbH

- L3Harris Technologies Inc.

- Lockheed Martin Corp.

- Stratasys Ltd.

- The Boeing Co.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The integration technology in the satellite manufacturing industry has revolutionized the production process of small satellites, offering significant advantages in terms of cost, time, and customization. This innovation has led to an increase In the number of missions utilizing small satellites for various space applications. Satellite manufacturing using the technology enables the production of complex satellite components, such as antennas, brackets, shields, housings, propulsion systems, and other essential parts. These components are typically manufactured using traditional methods, which can be time-consuming and costly. However, these parts can be produced quickly and efficiently, reducing the overall production time and cost.

Moreover, the space industry has identified several key areas where it can contribute to the development of satellite-based services. Communication, earth observation, navigation, internet access, telecommunications, and broadcasting services are some of the primary applications where small satellites are being utilized. In the context of military operations, the technology can be employed to produce customized satellite components for specific missions. The use of technology in satellite manufacturing also offers waste reduction benefits. Traditional manufacturing processes often result in significant waste, which can be costly and environmentally unsustainable. In contrast, it allows for the production of only the necessary parts, reducing waste and lowering production costs.

Furthermore, advanced printing technology and materials have enabled the production of nano and microsatellites, further expanding the scope of small satellite missions. These satellites are smaller in size and require fewer resources to launch and operate, making them an attractive option for organizations with budget constraints. The space industry is continuously exploring new ways to leverage the technology to enhance satellite production. Space agencies and satellite manufacturers are collaborating with material suppliers and printer technology providers to develop advanced printing techniques and materials suitable for space applications. The potential in satellite manufacturing is vast, and its impact on the industry is expected to be significant.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

158 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 75.62% |

|

Market Growth 2024-2028 |

USD 39.32 billion |

|

Market structure |

Concentrated |

|

YoY growth 2023-2024(%) |

61.87 |

|

Key countries |

US, China, UK, Germany, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this 3D Printing In Low-Cost Satellite Market Research and Growth Report?

- CAGR of the industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution to the industry in focus on the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, South America, and Middle East and Africa

- A thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.