Food Spray Drying Equipment Market Size 2024-2028

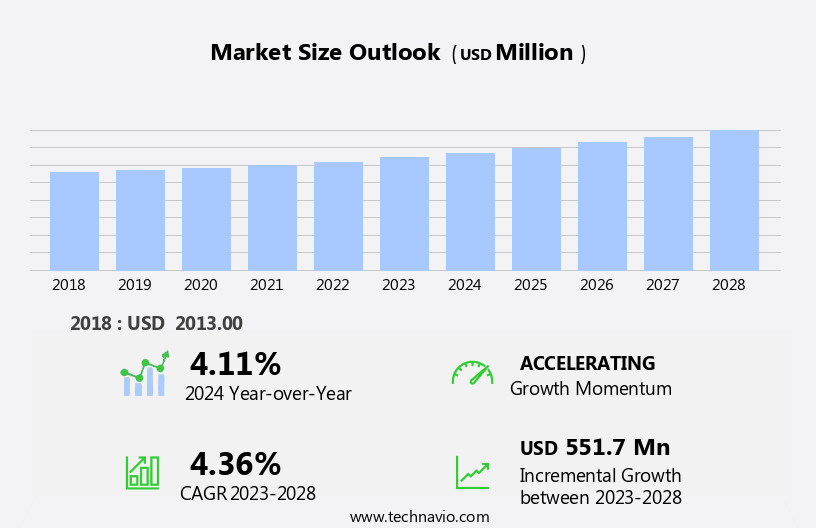

The food spray drying equipment market size is forecast to increase by USD 551.7 million at a CAGR of 4.36% between 2023 and 2028.

What will be the Size of the Food Spray Drying Equipment Market during the forecast period?

How is this Food Spray Drying Equipment Industry segmented?

The food spray drying equipment industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Milk products

- Plant products fish and meat proteins

- Fruit and vegetable products

- Carbohydrate products

- Others

- Product

- Two-stage spray dryer

- Multi-stage spray dryer

- Single-stage spray dryer

- Type

- Pressure single-fluid nozzle atomizer

- Rotary wheel atomizer

- Pneumatic two-fluid nozzle atomizer

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- UK

- North America

- US

- South America

- Middle East and Africa

- APAC

By Application Insights

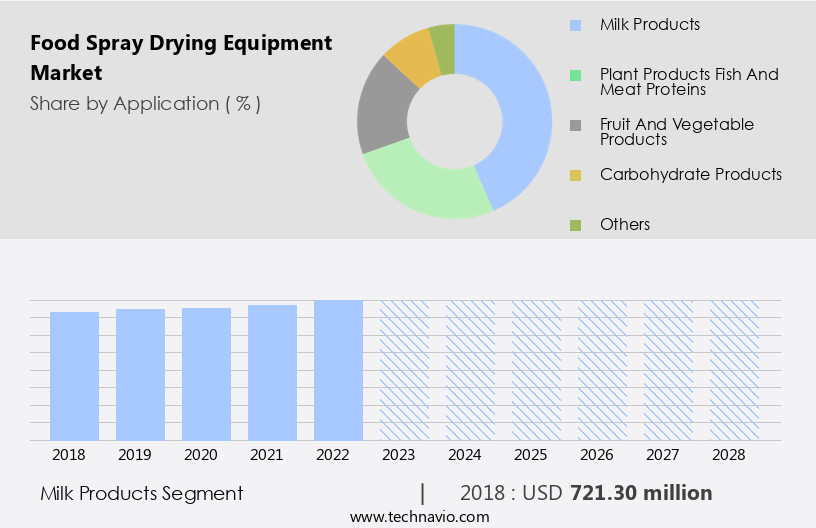

The milk products segment is estimated to witness significant growth during the forecast period.Spray drying equipment (FSDE) plays a crucial role In the production of milk powders and various milk-based products, including skim milk powder, whole milk powder, casein, infant formula, ice cream mix, whey permeate, and whey protein concentrates. Milk, being highly perishable with a short shelf life, is susceptible to microbial growth. FSDE addresses this challenge by removing water and preserving milk products, thereby increasing their shelf life. The transformation of liquid milk into powdered form facilitates easier transportation and storage. This factor, coupled with the growing demand for milk and milk-based products, is driving the market growth for FSDE. In the food sector, FSDE is also employed for drying fruits and vegetables, producing instant coffee, and creating powdered forms of functional foods, nutraceuticals, and convenience foods.

The technology is increasingly being adopted In the pharmaceutical industry for drug delivery systems, including nasal drug delivery, inhalation, and encapsulation. FSDE is also utilized In the production of specialty proteins, such as plant-based proteins, maltodextrin, food additives, and biodegradable polymers. FSDE's environmental benefits, such as thermal efficiency and reduced water usage, are significant. The technology enables the use of inert gases and liquid feeds, contributing to eco-friendly production processes. Additionally, FSDE is compatible with heat-sensitive products, including enzymes, probiotics, and bioactives, ensuring product integrity during the drying process. Key factors influencing the FSDE market include the increasing demand for extended shelf life, improved consistency, and cleanable systems In the nutraceutical industry.

Food safety laws and regulations, as well as product sensitivity, are also important considerations. The market is expected to grow due to the increasing popularity of processed foods, convenience foods, and nutritional supplements. In the beverage sector, FSDE is used for producing dry powdered products, such as instant coffee, powdered milk, and baby formula. The technology's ability to maintain product quality, texture, and nutritional value is a significant advantage. FSDE is also employed In the production of heat-sensitive products, such as enzymes, probiotics, and targeted drug delivery systems. The FSDE market is expected to grow due to the increasing demand for advanced materials, such as bioplastics and biodegradable polymers, in various industries.

The technology's potential applications in 3D printing and targeted drug delivery systems are also driving market growth. In conclusion, FSDE plays a vital role In the production of various food, beverage, and pharmaceutical products. Its ability to increase product shelf life, improve consistency, and maintain product quality is a significant advantage. The technology's environmental benefits, such as thermal efficiency and reduced water usage, are also driving market growth. The FSDE market is expected to continue growing due to the increasing demand for processed foods, convenience foods, and nutritional supplements.

Get a glance at the market report of share of various segments Request Free Sample

The Milk products segment was valued at USD 721.30 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 38% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The Food Spray Drying Equipment (FSDE) market is experiencing significant growth due to the increasing demand for dry powdered products in various sectors. In the food industry, instant coffee, powdered milk, and baby formula have high demand, particularly in Asia Pacific (APAC), where population growth and changing consumer preferences are driving production and consumption. Urbanization in developing countries like India and China has led to a shift in consumer lifestyle, resulting in increased demand for convenience foods and beverages. In the health sector, FSDE is used for producing pharmaceutical products, including drugs, enzymes, probiotics, and targeted drug delivery systems. Advanced materials, such as bioceramics, biodegradable polymers, and nanotechnology, are used in encapsulation and particle engineering for improved bioavailability and controlled release properties.

Environmental concerns have led to the adoption of eco-friendly equipment and the use of inert gases and liquid feeds. FSDE is also used In the nutraceutical industry for producing specialty proteins, solubility functionalities, and extended shelf life products. Factors such as thermal efficiency, product quality, and food safety laws are key considerations In the market. Key applications include processed foods, convenience foods, nutrients, and functional foods.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Food Spray Drying Equipment Industry?

- Rise in adoption of infant formula is the key driver of the market.

- Infant formula, available in powdered form, serves as a popular alternative to breastfeeding due to its high nutritional content, including vitamins, proteins, and fats. Factors such as evolving consumer lifestyles and the increasing number of working mothers have fueled the demand for this product. In particular, developing countries, like China, have experienced significant growth In the consumption of infant formula. In 2021, China held a substantial market share In the global infant formula industry. A rising trend among Chinese parents is the preference for infant formula produced abroad due to concerns over the quality of domestically manufactured formula. This dynamic underscores the market's potential for continued expansion.

What are the market trends shaping the Food Spray Drying Equipment Industry?

- Application of spray drying equipment for food encapsulation is the upcoming market trend.

- Spray drying equipment plays a significant role In the microencapsulation process of food materials. This technique, which involves spraying a liquid feed into hot air to form small droplets that evaporate instantly, is favored for its continuous, flexible, and economically viable nature. Microencapsulation is the process of encasing food ingredients, cells, enzymes, and other materials within small capsules. These capsules, or micro-capsules, consist of a core material and a protective shell or coating. The shell shields the food from external factors such as moisture, heat, and extreme conditions, thereby preserving the core's integrity and enhancing the delivery of bioactive molecules and living cells to food materials.

- The use of spray drying equipment in food microencapsulation contributes to improved food quality, extended shelf life, and enhanced functionality.

What challenges does the Food Spray Drying Equipment Industry face during its growth?

- High operating costs and thermal energy consumption is a key challenge affecting the industry growth.

- Spray drying is a process that consumes significant energy due to the large amounts required for atomization, heating, and vaporization of water In the products. This energy consumption is higher than the latent heat of evaporation of water, with approximately 5,000 kJ per kg needed for drying. The high installation and operational costs associated with spray drying equipment, which is a large and heavy piece of machinery, are another major challenge. Despite these challenges, spray drying remains a popular choice for food processing due to its ability to produce high-quality, free-flowing powders. The process is widely used in various industries, including food and beverage, pharmaceuticals, and chemicals, among others.

- The market for spray drying equipment is driven by factors such as increasing demand for convenient and ready-to-eat food products, rising health consciousness, and growing demand for functional food and beverage products. Additionally, advancements in technology, such as the use of energy-efficient equipment and alternative energy sources, are helping to mitigate some of the energy consumption concerns.

Exclusive Customer Landscape

The food spray drying equipment market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the food spray drying equipment market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, food spray drying equipment market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

Acmefil Engineering Systems Pvt. Ltd. - The company specializes in supplying advanced food spray drying equipment for various applications. Our product portfolio includes lab scale pilot spray dryers, rotary atomizer type spray dryers, and effluent spray dryers. These equipments cater to the research and development, as well as industrial-scale food processing industries, ensuring optimal product consistency and efficiency. Our commitment to innovation and quality positions us as a trusted partner In the global food processing market.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Acmefil Engineering Systems Pvt. Ltd.

- Advanced Drying Systems

- BUCHI Labortechnik AG

- Carrier Process Equipment Group Inc.

- Changzhou Jinqiao Spray Drying and Engineering Co. Ltd.

- Changzhou Lemar Drying Engineering Co. Ltd.

- Durr AG

- Freund Vector Corp.

- G. Larsson Starch Technology AB

- GEA Group AG

- Hemraj Engineering India LLP

- Labplant UK Ltd.

- New AVM Systech Pvt. Ltd.

- Saka Engineering Systems Pvt. Ltd.

- Shandong Tianli Energy Co. Ltd.

- SiccaDania

- SPX FLOW Inc.

- Tetra Laval SA

- Yamato Scientific Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a diverse range of technologies and applications, serving various industries including food, health, and beverage sectors. This market is driven by the growing demand for convenient, high-quality, and extended shelf life products. Chemicals play a crucial role In the food spray drying process, influencing product quality and shelf life. Maltodextrin, a common food additive, is often used as a carrier for active ingredients during spray drying. Plant-based proteins, such as soy, pea, and rice proteins, are also popular choices for spray drying due to their nutritional value and texture. Supercritical CO2 encapsulation and particle engineering are advanced technologies used In the food spray drying process.

These methods enable the creation of uniform particles with controlled size, shape, and composition. They are particularly useful for delivering sensitive active ingredients, such as enzymes, probiotics, and drugs, with improved bioavailability and controlled release properties. Biodegradable polymers and bioceramics are gaining popularity In the food spray drying industry due to their eco-friendly nature and potential to enhance powder properties. Nozzle atomizers are essential components of spray drying systems, enabling the conversion of liquid feeds into fine droplets for efficient drying. The pharmaceutical industry also utilizes spray drying technology for the production of dry powdered products, including drugs, enzymes, and nutraceuticals.

The advantages of spray drying in this sector include thermal efficiency, low temperatures, and the ability to produce powders with desired particle size and shape. Environmental concerns are increasingly influencing the food spray drying market, with a focus on eco-friendly equipment and inert gases to minimize emissions. Automated systems and temperature tracking are essential features for ensuring product consistency and meeting food safety laws. Specialty proteins, such as solubility functionality in instant coffee and powdered milk, and baby formula, are major applications of food spray drying. Heat-sensitive products, including fruits and vegetables, require careful handling during the spray drying process to preserve their nutritional value and texture.

Traditional drying methods, such as sun drying and oven drying, are being replaced by faster and more efficient spray drying processes. The convenience foods and processed foods industries rely heavily on spray drying for the production of nutrients, functional foods, and beverages. In conclusion, the market is a dynamic and evolving industry, driven by the demand for high-quality, convenient, and extended shelf life products. Technological advancements, environmental concerns, and regulatory requirements continue to shape the market, offering opportunities for innovation and growth.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

191 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.36% |

|

Market growth 2024-2028 |

USD 551.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.11 |

|

Key countries |

US, China, Germany, Japan, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Food Spray Drying Equipment Market Research and Growth Report?

- CAGR of the Food Spray Drying Equipment industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the food spray drying equipment market growth of industry companies

We can help! Our analysts can customize this food spray drying equipment market research report to meet your requirements.