Hydraulic Press Machine Market Size 2024-2028

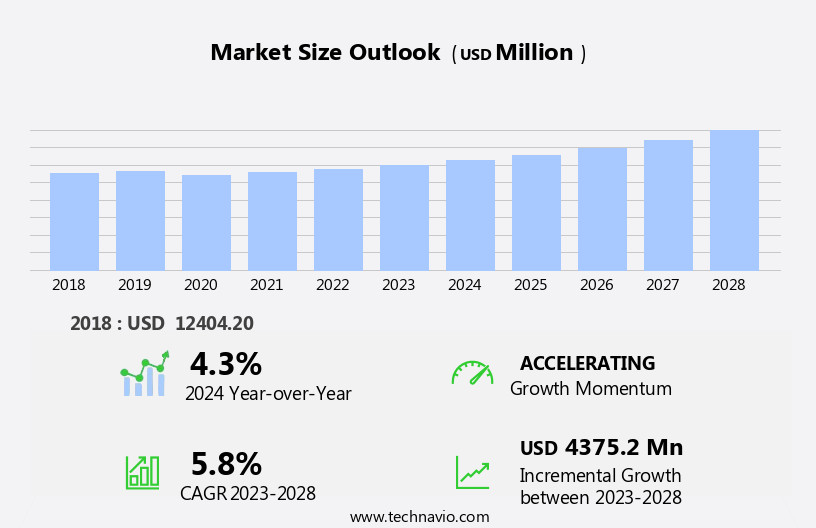

The hydraulic press machine market size is forecast to increase by USD 4.38 billion at a CAGR of 5.8% between 2023 and 2028.

- The market is experiencing significant growth due to the increasing demand for fabricated metal in various industries, particularly in the automotive sector. This sector's expansion is driving the need for advanced hydraulic press machines to produce high-quality, precision-engineered components. Another key trend in the market is the installation of Variable Frequency Drives (VFDs) in hydraulic press machines, which offer energy efficiency, improved productivity, and better control over the press operation. Moreover, technological advancements in sheet hydroforming have opened new opportunities for hydraulic press machine manufacturers. This process allows for the forming of complex shapes and contours in metal sheets, making it an attractive alternative to traditional metal fabrication methods.

- However, the market is not without challenges. Rising raw material costs and increasing competition from alternative manufacturing technologies, such as additive manufacturing, pose significant threats to market growth. To capitalize on the opportunities and navigate these challenges effectively, companies must focus on innovation, energy efficiency, and cost competitiveness. By investing in research and development, implementing lean manufacturing practices, and collaborating with industry partners, hydraulic press machine manufacturers can differentiate themselves in the market and maintain a competitive edge.

What will be the Size of the Hydraulic Press Machine Market during the forecast period?

- The market encompasses various types of presses, including open frame, C-frame, H-frame, and servo presses, each catering to diverse press work requirements. Tonnage capacity is a significant factor influencing the selection of these machines for metal shaping and manufacturing units. Pascals Law governs the functioning of hydraulic presses, utilizing compressive force from liquid pressure to shape metals. Advancements in technology have led to the integration of 3D printing technology and pneumatic presses, enhancing precision and flexibility in metal forming processes. The general machinery industry benefits from these machines' high compressive strength and ability to apply kinetic energy.

- Presses find applications in various sectors, such as automotive manufacturing for lightweight vehicles and the medical industry for producing components with exacting standards. Machine tools like gantry presses and hydraulic cylinders contribute to high-precision manufacturing. Market trends include the adoption of servo presses for their energy efficiency and improved control, as well as the integration of shear stress and embossing capabilities for increased versatility. The market's evolution is driven by the need for greater precision and efficiency in manufacturing processes.

How is this Hydraulic Press Machine Industry segmented?

The hydraulic press machine industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Transportation

- General machinery

- Others

- Type

- C-frame

- H-frame

- 4-post hydraulic press

- Others

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- UK

- North America

- US

- Middle East and Africa

- South America

- APAC

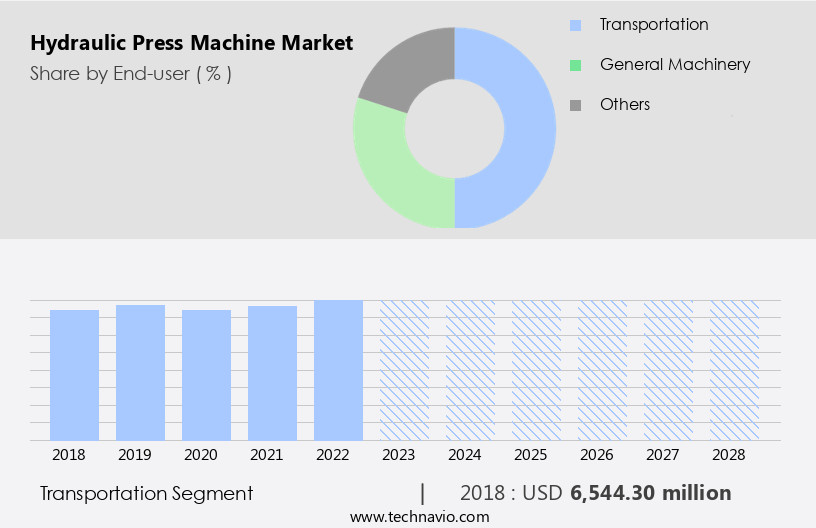

By End-user Insights

The transportation segment is estimated to witness significant growth during the forecast period.

The market encompasses various types of presses, including C-Frame Presses and 4-column hydraulic presses, which utilize liquid pressure to generate compressive force through hydraulic cylinders. Smart Technologies play a significant role in enhancing the functionality of these machines through automation, remote monitoring, and the integration of Internet of Things and Variable Frequency Drives. The General Machinery industry relies heavily on hydraulic presses for metal shaping processes such as stamping, trimming, and press work. Aerospace, plastic processing, laminating, and medical industries are key end-users of these machines. Composite materials, rubber processing, and fabricated metal are among the materials being formed using hydraulic presses.

Infrastructure Development initiatives in various sectors, including oil & gas industries and construction, have led to increased demand for heavy-duty forming and portable presses. Servo Presses and Servo-Hydraulic Presses offer higher precision and are widely adopted for high-precision manufacturing applications. The market also witnesses the adoption of advanced technologies such as Artificial Intelligence, 3D printing, and Sustainable Manufacturing, which contribute to increased efficiency and productivity. The growing demand for lightweight vehicles and the increasing use of sensors and programmable systems further propel market growth. Precision and compressive strength are crucial factors in the selection of hydraulic presses, with various tonnage capacities available to cater to diverse industry requirements.

The market is expected to continue evolving, with ongoing research and development in areas such as kinetic energy recovery, ergonomic design, and the integration of Pascals law principles.

Get a glance at the market report of share of various segments Request Free Sample

The Transportation segment was valued at USD 6.54 billion in 2018 and showed a gradual increase during the forecast period.

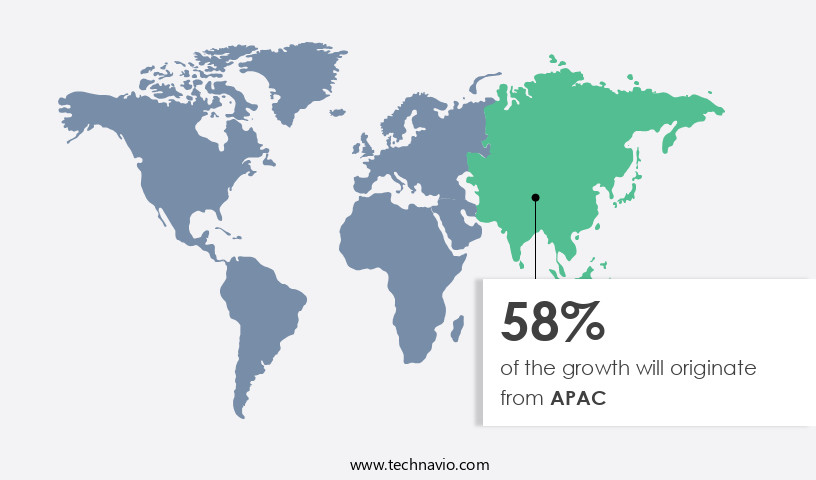

Regional Analysis

APAC is estimated to contribute 58% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in Asia Pacific (APAC) is experiencing significant growth due to the expanding automotive and general machinery industries in the region. China, India, Japan, South Korea, Thailand, and Indonesia are key contributors to this market growth. In India, initiatives like Skill India and Make in India have fostered a favorable business environment, attracting manufacturers from developed economies to establish manufacturing units. The high demand for automobiles, general machinery, and electronic goods in APAC is driving the need for hydraulic press machines. These machines are integral to various industries, including metal forming, construction, forging, and fabricated metal production, among others.

In the automotive sector, they are used for stamping, trimming, and blanking processes. In the general machinery industry, they are employed for press work, laminating, and moulding. Hydraulic press machines are also crucial in the aerospace, medical, and electrical & electronics industries for applications such as metal shaping, precision forming, and 3D printing. The integration of smart technologies, automated systems, variable frequency drives, and sensors in hydraulic press machines is enhancing their capabilities and efficiency. Additionally, the adoption of servo-hydraulic presses, open frame presses, and H-frame hydraulic presses is increasing. The use of composite materials, shear stress, and tonnage capacity are essential factors influencing the market trends.

The market is also witnessing the adoption of sustainable manufacturing practices and the integration of artificial intelligence and kinetic energy recovery systems to improve productivity and reduce energy consumption. Infrastructure development and the oil & gas industries are other significant end-users of hydraulic press machines.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Hydraulic Press Machine Industry?

- Surge in demand for fabricated metal in automotive sector is the key driver of the market.

- The market has experienced notable growth, primarily due to the automotive industry's expanding requirements. This trend can be attributed to several factors. For instance, the increasing preference for electric vehicles (EVs) has led to a surge in production as governments worldwide encourage cleaner transportation alternatives. In 2020, electric car sales in the US reportedly rose by 43%, according to the US Department of Energy.

- Additionally, stricter pollution regulations have forced automakers to adopt lightweight materials like aluminum and high-strength steel to reduce emissions. Between 2019 and 2020, European carmakers managed to decrease average CO2 emissions by 22% through the use of these materials, as reported by the European Automobile Manufacturers Association.

What are the market trends shaping the Hydraulic Press Machine Industry?

- Installation of VFDs in hydraulic press machines is the upcoming market trend.

- Over the past three decades, there was a common belief that the market for hydraulic press machines would wane due to the rising preference for electric press machines. However, advancements in technology and the integration of electric motors to power hydraulic pumps have led to improved production output and efficiency for hydraulic press machines. Electric motors, which serve as the power source for hydraulic pumps, are primarily driven by alternating current and operate on voltage levels ranging from 120V to 600V.

- This innovation has enabled hydraulic press machines to remain competitive in the manufacturing industry. Despite earlier perceptions, hydraulic press machines continue to play a significant role in manufacturing processes, offering advantages such as greater force and precision compared to electric press machines.

What challenges does the Hydraulic Press Machine Industry face during its growth?

- Advances in sheet hydroforming is a key challenge affecting the industry growth.

- Hydraulic press machines are essential tools in metal fabrication, enabling the creation of precise bends in metallic sheets using a matched punch-and-die set. For a single bend, these machines offer convenience and simplicity. However, when multiple bends are required, the need to frequently change die sets results in decreased production output due to the additional time spent. Moreover, the operator must check the angle for each bend, which depends on their expertise, further increasing production time.

- These factors present challenges in the market, making efficiency and accuracy key considerations for companies and end-users alike.

Exclusive Customer Landscape

The hydraulic press machine market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the hydraulic press machine market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, hydraulic press machine market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Andritz AG - Hydraulic press machines, including hydraulic test presses and forming presses, deliver dependable performance for diverse industrial applications. These advanced machines, offered by the company, ensure efficient manufacturing processes and high-quality output. Engineered for durability and precision, they cater to various industries, enhancing productivity and profitability.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Andritz AG

- Betenbender Manufacturing Inc.

- Amino North America Corp.

- AP and T AB

- Asai Corp.

- Beckwood Press

- Dake

- DEES Hydraulic Industrial Co. Ltd.

- Dieffenbacher GmbH

- Eagle Press Equipment Co. Ltd.

- G.Siempelkamp GmbH and Co. KG

- Komatsu Ltd.

- Macrodyne Technologies Inc.

- Osterwalder AG

- Schuler AG

- SMS group GmbH

- SUTHERLAND PRESSES

- Worcester Presses Ltd

- Yangli Group Corporation Ltd.

- Yoshizuka Seiki Co Ltd

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a diverse range of machinery used in various industries for shaping and processing materials through the application of compressive force. These machines, which include C-frame presses and 4-column hydraulic presses, utilize hydraulic cylinders to generate the necessary pressure. Liquid pressure plays a crucial role in the operation of hydraulic presses. The general machinery industry relies heavily on these machines for tasks such as stamping, trimming, and mechanical press work. Composite materials, metals, ceramics, and even non-traditional materials like rubber are processed using hydraulic presses. Advancements in technology have led to the integration of smart technologies and automated systems into hydraulic presses.

These innovations include variable frequency drives, sensors, servo-hydraulic presses, and programmable systems. The Internet of Things (IoT) has also made remote monitoring and control possible, enhancing efficiency and productivity. Hydraulic presses find applications in numerous industries, including aerospace, automotive, electrical & electronics, construction, and the oil & gas industries. In the aerospace sector, these machines are used for manufacturing high-precision components. In the automotive industry, they are employed in the production of lightweight vehicles. In the electrical & electronics industry, they are used for manufacturing intricate components. The hydraulic press market is witnessing significant growth due to the increasing demand for precision manufacturing and the adoption of sustainable manufacturing practices.

The market is also driven by the need for high-performance machinery in infrastructure development and the production assembly lines of various industries. Advancements in technology have led to the development of new types of hydraulic presses, such as gantry presses, H-frame presses, and open frame presses. These machines offer advantages such as increased tonnage capacity, improved precision, and ergonomic design. The hydraulic press market is also witnessing the integration of advanced technologies like artificial intelligence and 3D printing technology. These innovations are expected to revolutionize the industry by enabling the production of complex components with minimal human intervention. The market for hydraulic presses is diverse and dynamic, with new technologies and applications constantly emerging.

The market's evolution is driven by various factors, including the demand for high-performance machinery, the adoption of sustainable manufacturing practices, and the integration of advanced technologies. Pascal's Law, which describes the relationship between pressure and area, plays a fundamental role in the operation of hydraulic presses. The ability to generate compressive force through the transfer of liquid pressure is a key advantage of these machines. In conclusion, the market is a dynamic and evolving industry that plays a crucial role in various sectors. The market's growth is driven by the demand for high-performance machinery, the adoption of sustainable manufacturing practices, and the integration of advanced technologies.

The future of the hydraulic press market looks promising, with new applications and innovations constantly emerging.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

174 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.8% |

|

Market growth 2024-2028 |

USD 4375.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.3 |

|

Key countries |

China, Japan, Germany, US, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Hydraulic Press Machine Market Research and Growth Report?

- CAGR of the Hydraulic Press Machine industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the hydraulic press machine market growth of industry companies

We can help! Our analysts can customize this hydraulic press machine market research report to meet your requirements.