Aluminum Nitride (ANI) Powder Market Size 2025-2029

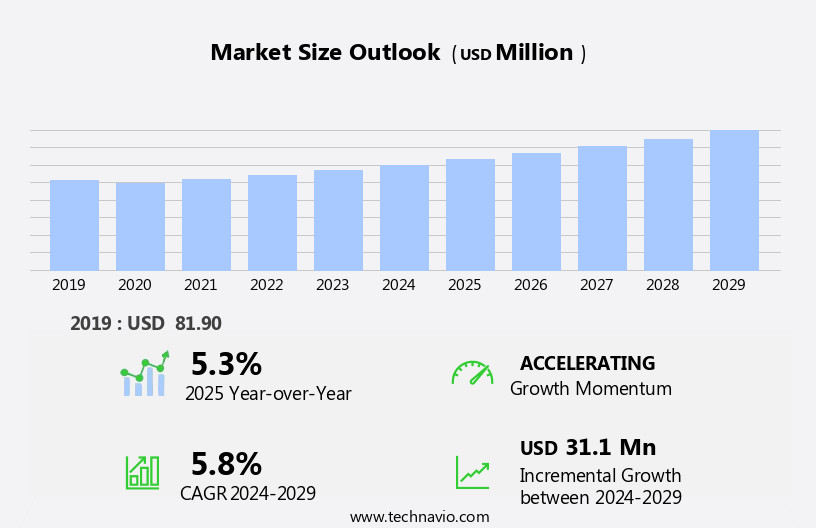

The aluminum nitride (ani) powder market size is forecast to increase by USD 31.1 million at a CAGR of 5.8% between 2024 and 2029.

- The market is experiencing significant growth due to the excellent thermal conductivity property of ANI, which is a key driver for its increasing adoption in various industries, particularly in the semiconductor sector. The semiconductor industry's expansion is fueled by the rising demand for electronic devices, such as smartphones, laptops, and servers, leading to an increased need for efficient heat management solutions. However, the market growth is facing challenges due to the slowdown of the manufacturing sector in China, a major consumer of ANI. This economic downturn is causing a decrease in demand for ANI in the electronics industry, as well as in other sectors such as automotive and aerospace.

- Despite this, the long-term outlook for the ANI Powder Market remains positive, with opportunities arising from the ongoing development of advanced technologies, such as 5G and the Internet of Things (IoT), which require high-performance materials for thermal management applications. Companies seeking to capitalize on these opportunities must stay informed of market trends and be agile in their business strategies to navigate the challenges effectively.

What will be the Size of the Aluminum Nitride (ANI) Powder Market during the forecast period?

- The aluminum nitride (AIN) powder market encompasses the production and supply of high-performance aluminum nitride, a versatile ceramic material renowned for its exceptional thermal conductivity, hexagonal crystal structure, and excellent electrical insulation qualities. AIN powder is derived from carbo thermal reduction of aluminum and gaus ammonia. Its unique properties make it an optimum material for various industries, including telecommunications and electronics, where it is utilized in the manufacturing of heat sinks, electrical components, and thermal management systems. The global AIN powder market is driven by the increasing demand for lightweight, high-performance materials in the electronics industry. The material's exceptional electrical insulation rate, mechanical strength, and thermal expansion properties make it a preferred choice for high-reliability applications.

- Moreover, the growing emphasis on environmentally friendly practices in manufacturing processes further boosts the market's growth. The market is expected to continue expanding, driven by the increasing adoption of AIN powder in advanced technologies, such as heat sinks for high-power electronic components and thermal management solutions for electric vehicles.

How is this Aluminum Nitride (ANI) Powder Industry segmented?

The aluminum nitride (ani) powder industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Technique

- Direct nitridation

- Carbothermal reduction

- Application

- Thermal conductive material

- Electrical component

- Others

- Grade Type

- High purity

- Standard grade

- Ultra-fine

- Form Factor

- Dry powder

- Wet processed powder

- Geography

- APAC

- Australia

- China

- India

- Japan

- South Korea

- North America

- US

- Canada

- Europe

- France

- Germany

- UK

- Middle East and Africa

- South America

- APAC

By Technique Insights

The direct nitridation segment is estimated to witness significant growth during the forecast period.

The market is driven by the increasing demand for high-performance materials in various industries. ANI powder, with its hexagonal crystal structure and electrical insulation qualities, is a high-demand ceramic material. Its production primarily involves direct nitridation or carbothermal reduction using gaus ammonia. The market is witnessing significant growth due to the technological advancements in the semiconductor manufacturing industry, telecommunications, and power electronics. ANI powder's high thermal conductivity, mechanical strength, and electrical insulation rate make it an optimum material for electronic substrates, chip carriers, heat sinks, and electronic components. The market is also influenced by the technological growth in the electric vehicle industry, where ANI powder is used for heat dissipation in power electronics and battery management systems.

The future trend is towards the use of high-purity ANI powder in energy-efficient devices, such as heat sink materials and ceramic substrates for electronic components. The market is expected to experience a steady demand-supply balance, with technological factors playing a crucial role in its growth.

Get a glance at the market report of share of various segments Request Free Sample

The Direct nitridation segment was valued at USD 51.80 million in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

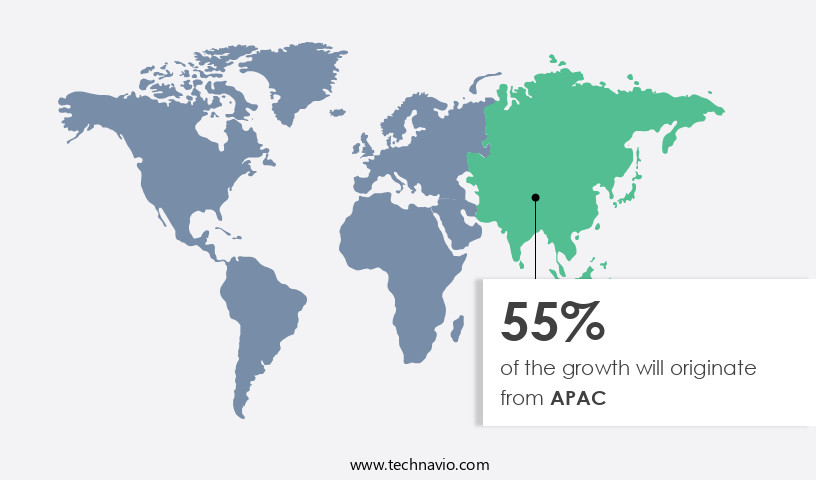

APAC is estimated to contribute 55% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

Aluminum nitride (ANI) powder is a high-performance ceramic material widely used as an intermediate in the manufacturing of LEDs and semiconductors. In 2023, the APAC region dominated the global ANI powder market due to its significant production and consumption. Key consumers of ANI in APAC include China, Japan, South Korea, India, Australia, New Zealand, and Indonesia. The region's rapid market growth is driven by its manufacturing industrial base and the increasing global demand for LEDs and semiconductors. Notable contributors to the global semiconductor and industrial LED sectors are China, Japan, Taiwan, Vietnam, South Korea, Singapore, and Malaysia.

ANI powder's unique properties, such as high thermal conductivity, hexagonal crystal structure, and electrical insulation qualities, make it an optimum material for various applications, including electric cars, thermal management, and high-performance ceramics. Its use in electric vehicles and power electronics contributes to energy-efficient devices, while its deep UV transparency and thermal expansion properties make it ideal for use in electronic substrates, chip carriers, and heat sinks. The market's future trend is expected to be influenced by technological growth in the telecommunications industry and the increasing demand for high-purity ANI powder as a substrate material in semiconductor manufacturing. ANI powder's environmental friendliness, high electrical insulation rate, and desirable thermal management properties further enhance its appeal.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Aluminum Nitride (ANI) Powder Industry?

- Excellent thermal conductivity property of ANI is the key driver of the market.

- ANI powder, a crucial material in the manufacturing of ceramic substrates, offers significant advantages in various industries. In solar panels, ANI-based ceramic substrates effectively collect heat from sun rays due to their high thermal conductivity. Similarly, in electronics, semiconductor packaging, and power electronics, thermal conductivity of adhesives can be enhanced by incorporating ANI powder as a filler material. Compared to other high conductivity ceramic materials like beryllium oxide (BeO) and cubic boron nitride (c-BN), ANI is preferred due to its numerous benefits.

- BeO, which is being replaced in applications such as RF windows, crucibles, and other semiconductor equipment parts due to its toxic nature, is being superseded by ANI. The production process of c-BN is more complex, making ANI a more viable option. Thus, ANI powder plays a pivotal role in enhancing thermal conductivity in various applications, making it a preferred choice over other high conductivity ceramics.

What are the market trends shaping the Aluminum Nitride (ANI) Powder Industry?

- Increasing demand for semiconductors is the upcoming market trend.

- Semiconductor materials, including Aluminum Nitride (ANI), exhibit unique properties that make them essential components in various industries. ANI is known for its ability to act as both an insulator and a partial conductor, which facilitates rapid switching and modulation in circuits. This property is achieved when external factors, such as electric fields, temperature, and light, influence the semiconductor material. The external factors cause electrons in ANI to cross the narrow bandgap between the valence band and the conduction band. This short distance between the bands allows for efficient electron transition in the presence of electric or magnetic fields.

- The semiconductor industry relies heavily on materials like ANI due to their versatility and ability to modulate current flow, enabling the production of advanced electronic devices. In summary, Aluminum Nitride (ANI) is a vital semiconductor material that offers the unique property of being both an insulator and a conductor when influenced by external factors. Its short bandgap distance enables efficient electron transition, making it an indispensable component in the semiconductor industry for the production of advanced electronic devices.

What challenges does the Aluminum Nitride (ANI) Powder Industry face during its growth?

- Slowdown of manufacturing sector in China is a key challenge affecting the industry growth.

- Aluminum Nitride (ANI) powder is a significant industrial material, with China being a major producer and consumer due to its extensive manufacturing sector. China manufactures various products, including metals and alloys, automotive and aircraft components, industrial machinery, and electrical and electronic devices. However, the Chinese economy and manufacturing sector are currently facing challenges. A global export decline and low foreign investments have impacted the industry, causing manufacturing overcapacity and decreasing profits for some companies.

- Additionally, the rising cost of labor in China is reducing its appeal as a preferred investment destination. Despite these challenges, the demand for high purity alumina, including ANI powder, remains strong due to its diverse applications in various industries.

Exclusive Customer Landscape

The aluminum nitride (ani) powder market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the aluminum nitride (ani) powder market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, aluminum nitride (ani) powder market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Accumet Materials Co. - The company specializes in the production of high-density alumina ceramic components using aluminum nitride powder. This powder can be processed through uniaxial or cold isostatic pressing and sintering techniques. Additionally, the company provides Ready to Press Alumina Powders for streamlined manufacturing processes. Our offerings cater to various industries, aligning with our commitment to delivering superior ceramic solutions.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Accumet Materials Co.

- American Elements

- HexaTech Inc.

- Liaoning Desunmet Special Ceramics Manufacturing Co. Ltd.

- MARUWA CO. LTD.

- Merck KGaA

- Nano Research Elements Inc.

- Nanoshel LLC

- Resonac Holdings Corp.

- Shandong Pengcheng Advanced Ceramics Co. Ltd.

- SkySpring Nanomaterials Inc.

- Surmet Corp.

- Thermo Fisher Scientific Inc.

- Thrutek Applied Materials Co. Ltd.

- Tokuyama Corp.

- TOYO ALUMINIUM K.K.

- Xiamen JuCi Technology Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Aluminum nitride (Ani), a vital ceramic material, is renowned for its unique properties, making it a preferred choice in various industries. Its hexagonal crystal structure is a significant factor contributing to its high thermal conductivity, which makes it an excellent material for thermal management applications. The production of aluminum nitride powder involves several processes, including carbothermal reduction using gaus ammonia. This process results in a high-purity powder, which is essential for the material's optimal electrical insulation qualities and mechanical strength. The demand for aluminum nitride in the electronics industry is driven by its high thermal conductivity and electrical insulation rate.

It is widely used in the manufacturing of electronic substrates, chip carriers, and other electronic components. The material's thermal expansion properties make it an ideal heat sink material, ensuring safety and functionality in high-performance electronic devices. The technological growth in the telecommunications industry has led to an increased demand for aluminum nitride in the production of high-performance ceramics. Its deep UV transparent properties make it an excellent material for optical applications, including heat sinks and other thermal management systems. The use of aluminum nitride in the semiconductor manufacturing sector is another significant market for this material. Its high thermal conductivity and electrical insulation qualities make it an ideal substrate material for power electronics and energy-efficient devices.

Environmentally friendly practices have become increasingly important in various industries, and aluminum nitride's production process is no exception. Direct nitridation and carbothermal reduction are two production methods that minimize the environmental impact of aluminum nitride production. The future trend in the aluminum nitride market is towards the development of new applications in emerging industries, such as electric vehicles and renewable energy. The material's high thermal conductivity and electrical insulation properties make it an excellent material for heat dissipation in electric cars and power electronics. The aluminum nitride market is influenced by both demand-side and supply-side factors. The demand for high-performance materials in various industries is driving the growth of the market, while the supply side is influenced by technological factors, such as the development of new production methods and the availability of high-purity aluminum nitride powder.

In , aluminum nitride is a versatile and essential ceramic material with unique properties that make it an ideal material for various applications in the electronics, telecommunications, and semiconductor manufacturing industries. Its production process is continuously evolving to meet the demands of these industries and to minimize its environmental impact. The future of the aluminum nitride market lies in the development of new applications in emerging industries, such as electric vehicles and renewable energy.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

233 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.8% |

|

Market growth 2025-2029 |

USD 31.1 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

5.3 |

|

Key countries |

US, China, Japan, India, South Korea, Canada, Australia, UK, Germany, and France |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Aluminum Nitride (ANI) Powder Market Research and Growth Report?

- CAGR of the Aluminum Nitride (ANI) Powder industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the aluminum nitride (ani) powder market growth of industry companies

We can help! Our analysts can customize this aluminum nitride (ani) powder market research report to meet your requirements.