Italy Factory Automation And Industrial Controls Market Size 2024-2028

The Italy factory automation and industrial controls market size is forecast to increase by USD 2.42 billion at a CAGR of 7.6% between 2023 and 2028.

- The market is witnessing significant growth due to several key trends. The need for simplifying complex manufacturing activities is driving the adoption of advanced automation systems. Virtualization of automation control systems is another trend gaining traction, as it enables remote access and management of industrial processes. Italy is at the forefront of Industry 4.0 adoption, with a strong emphasis on smart manufacturing, digital twins, cloud-based automation, edge computing, and M2M networking. However, the lack of effective interoperability among different automation systems poses a major challenge to market growth. This report provides an in-depth analysis of these trends and the market growth factors shaping the Italian Factory Automation and Industrial Controls Market. It offers insights into the opportunities and challenges that lie ahead for market participants. The report also provides a comprehensive analysis of the market landscape, including the drivers, challenges, and future outlook. By understanding these trends and factors, businesses can make informed decisions and capitalize on the opportunities In the Italian Factory Automation and Industrial Controls Market.

What will be the size of the Italy Factory Automation And Industrial Controls Market during the forecast period?

- The Italian factory automation and industrial controls market is experiencing significant growth due to increasing focus on cost reduction, process optimization, and digital transformation in various industries, including oil and gas, energy utilities, and manufacturing. Industrial cybersecurity is a major concern, driving the demand for advanced security solutions. Predictive maintenance, human-robot collaboration, and AI-enabled automation components are also key trends. The market is witnessing a shift towards remote monitoring, operational efficiency, and energy saving, driven by labor scarcity and the need for industrial automation consulting.

- Furthermore, technology adoption is accelerating, with the integration of IoT, data analytics, and sensor networks into automation solutions. The market is expected to continue growing, with a focus on advanced manufacturing, autonomous systems, and industrial robotics.

How is this market segmented and which is the largest segment?

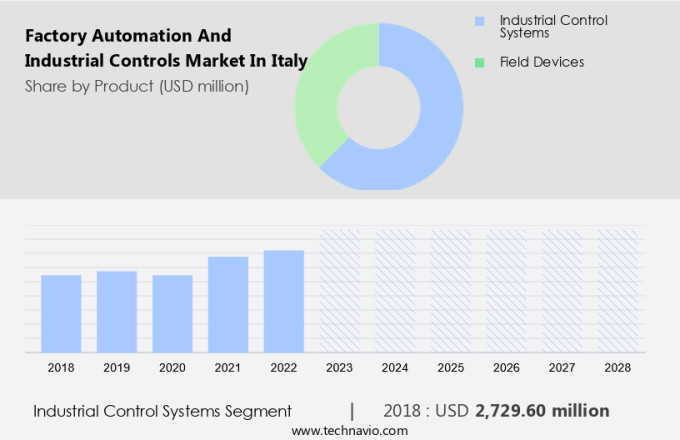

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Product

- Industrial control systems

- Field devices

- End-user

- General industry

- Automotive

- Consumer goods

- Others

- Geography

- Italy

By Product Insights

- The industrial control systems segment is estimated to witness significant growth during the forecast period.

Industrial control systems play a crucial role in optimizing manufacturing processes by automating and monitoring various operations in factories and industrial sectors. The market for industrial control systems in Italy is poised for growth due to the increasing demand for real-time traffic behavior monitoring, machine-to-machine communication, and cloud computing in industrial applications. Additionally, the need to minimize downtime, streamline processes, and reduce operational expenses is driving the adoption of advanced industrial control systems. Sensors and anomaly detection systems are becoming increasingly important in industrial settings to ensure efficient production and prevent potential cyber-attacks. The integration of nanotechnology and nanoscale assembly systems may further enhance the capabilities of industrial control systems In the future. Overall, the market for industrial control systems in Italy is expected to grow steadily during the forecast period, driven by the evolving needs of the industrial sectors, including railway and network industries.

Get a glance at the market share of various segments Request Free Sample

The industrial control systems segment was valued at USD 2.73 billion in 2018 and showed a gradual increase during the forecast period.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in adoption of Italy Factory Automation And Industrial Controls Market?

Need for simplification of complex manufacturing activities is the key driver of the market.

- In today's industrial landscape, the integration of factory automation and industrial controls technology has become essential for maintaining productivity and operational efficiency in various sectors, including oil & gas, manufacturing, transportation, and energy utilities. The increasing complexity of production processes, driven by customized product requirements and cyclic demand, necessitates advanced technology equipment and intelligent devices. Industrial control systems, such as SCADA, DCS, and PLCs, play a crucial role in monitoring and managing these intricate processes, systems, and logistics. Moreover, the advent of technologies like IoT, machine learning, AI, and deep learning has led to the development of collaborative robotics, context-aware systems, and predictive maintenance solutions.

- Moreover, these technologies enable real-time traffic behavior monitoring, anomaly detection, and operational cost reduction. Nanotechnology and nanoscale assembly systems have further enhanced the capabilities of industrial automation, leading to high-yield implementation and flexible manufacturing. However, the growing interconnectivity of industrial systems poses a significant cybersecurity risk, with cyber-attacks on industrial control networks becoming increasingly common. To mitigate these risks, it is essential to prioritize security in industrial IoT and SCADA systems, ensuring that connected devices are secure and communication protocols are strong.

What are the market trends shaping the Italy Factory Automation And Industrial Controls Market?

Virtualization of automation control systems is the upcoming trend In the market.

- Factory automation and industrial controls in Italy are experiencing significant advancements, particularly in sectors such as oil & gas, manufacturing, transportation, and energy utilities. The integration of technology equipment, including nanotech sensors, programmable logic controllers, and SCADA systems, is driving productivity and operational efficiency. The use of connectivity, such as machine-to-machine communication and Internet of Things (IoT) technologies, enables real-time data analysis and predictive maintenance. Cybersecurity remains a critical concern, with the increasing risk of cyber-attacks targeting industrial control systems. Industrial automation is becoming more intelligent, with the implementation of AI, deep learning, and cobots that exhibit context awareness.

- In addition, flexible manufacturing systems and collaborative robotics are also gaining popularity, enabling high yield and efficient assembly workflows. Nanotechnology and nanoscale assembly systems are revolutionizing the manufacturing process, with applications in semiconductor & electronics, healthcare, and agriculture. Industrial IoT is transforming logistics and operations processing, with real-time traffic behavior monitoring and predictive maintenance. Cloud computing and programmable, intelligent devices enable remote monitoring and control of industrial processes. The implementation of cybersecurity measures, such as secure communication protocols and remote terminal units, is essential to mitigate the risks of cyber-attacks. The use of AI, machine learning, and computer vision technologies can enhance operational efficiency and decision-making capabilities.

What challenges does Italy Factory Automation And Industrial Controls Market face during the growth?

Lack of effective interoperability is a key challenge affecting the market growth.

- The Italian factory automation and industrial controls market faces challenges due to the lack of effective interoperability between various automation solutions and control technologies. End-users in industries such as oil and gas, power, chemicals and petrochemicals, and water and wastewater encounter interoperability issues when the interface fails to support the latest factory automation systems. This challenge arises from the increasing complexity of modern industrial systems and facilities, which incorporate multiple devices and systems with diverse configurations. Integrating these systems poses a significant hurdle for end-users, as compatibility and interoperability become major concerns. The implementation of advanced technologies like nanotech sensors, machine-to-machine communication, IoT, and AI in industrial automation systems further complicates the integration process.

- Additionally, cybersecurity threats, such as cyber-attacks, pose a significant risk to the operational efficiency of industrial control systems. To mitigate these challenges, skilled professionals are required to ensure the successful implementation of these advanced technologies while maintaining operational cost efficiency. Industrial sectors, including manufacturing, transportation, healthcare, and energy utilities, are increasingly adopting intelligent devices, collaborative robotics, context awareness, and predictive maintenance systems to enhance productivity and operational efficiency. These technologies require seamless connectivity and communication between various devices and systems, making interoperability a crucial factor for the growth of the Italian factory automation and industrial controls market.

Exclusive Italy Factory Automation And Industrial Controls Market Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the market.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- 3D Automazione Srl

- ABB

- Cd Automation S.r.l.

- Comau Spa

- CTA ELECTRONICS SRL

- Emerson Electric Co.

- FANUC Corp.

- Fuji Electric Co. Ltd.

- Honeywell International Inc.

- Mitsubishi Electric Corp.

- OMRON Corp.

- PROTEO ENGINEERING SRL

- Robert Bosch GmbH

- Rockwell Automation Inc.

- Schneider Electric SE

- SDI Automazione indutriale SPA

- Siemens AG

- Sitec Srl

- Yaskawa Electric Corp.

- Yokogawa Electric Corp.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Italy, renowned for its rich cultural heritage and industrial prowess, is at the forefront of embracing advanced technology to drive productivity and efficiency in its manufacturing sectors. The adoption of factory automation and industrial controls is a testament to this technological evolution. In this article, we delve into the market dynamics of this burgeoning industry, focusing on the unique aspects of the Italian market. Factory automation refers to the use of technology to control and monitor industrial processes, increasing efficiency and reducing human intervention.

Moreover, industrial controls, on the other hand, are the systems used to regulate and optimize various industrial processes. Both these technologies are integral to the modern industrial landscape, enabling high-yield production and operational efficiency. The Italian market for factory automation and industrial controls is characterized by a strong focus on connectivity and communication. The Internet of Things (IoT) is transforming the way industries operate, with intelligent devices exchanging data in real-time to optimize processes and improve decision-making. This trend is particularly prominent in sectors such as transportation, energy utilities, and manufacturing. The implementation of programmable logic controllers (PLCs) and SCADA systems is widespread in Italy, enabling real-time monitoring and control of industrial processes.

In addition, these systems allow for flexible manufacturing and predictive maintenance, reducing downtime and increasing productivity. Moreover, the integration of artificial intelligence (AI) and machine learning algorithms is revolutionizing the way industries operate, with context-aware systems making informed decisions based on data. The Italian market for factory automation and industrial controls is also witnessing an increase in the adoption of collaborative robotics, or cobots. These robots work alongside human operators, automating repetitive tasks and enhancing safety. The use of nanotechnology, such as nanoscale assembly systems and nanotech sensors, is another emerging trend In the Italian market. These technologies offer high precision and flexibility, making them ideal for applications in semiconductor & electronics manufacturing.

Furthermore, the competitive landscape of the Italian market is diverse, with a strong presence of local and international players. The adoption of factory automation and industrial controls is driven by the need for operational efficiency, reduced operational costs, and the desire to stay competitive in a globalized economy. However, the Italian market is not without its challenges. Cybersecurity is a major concern, with the increasing interconnectivity of industrial processes making them vulnerable to cyber-attacks. The shortage of skilled professionals In the field of factory automation and industrial controls is another challenge.

In addition, with a strong focus on connectivity, communication, and advanced technologies, the Italian industry is well-positioned to drive productivity and efficiency in its manufacturing sectors. However, challenges such as cybersecurity and the shortage of skilled professionals must be addressed to fully realize the potential of this industry. In the coming years, we can expect to see continued innovation and growth In the Italian market for factory automation and industrial controls. The integration of AI, machine learning, and nanotechnology is set to transform the way industries operate, with real-time data analysis and predictive maintenance becoming the norm. The future is bright for this industry, with endless opportunities for growth and innovation.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

141 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 7.6% |

|

Market growth 2024-2028 |

USD 2.42 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

6.9 |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across Italy

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements Get in touch