Fatigue Testing Machine Market Size 2024-2028

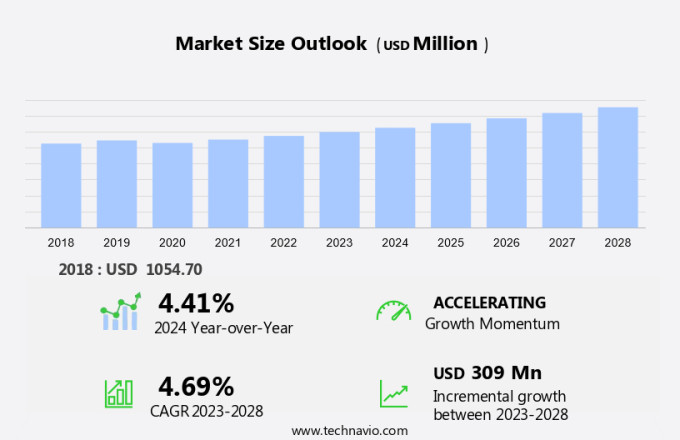

The fatigue testing machine market size is estimated to grow by USD 309 million at a CAGR of 4.69% between 2023 and 2028. The market is experiencing significant growth, driven by increasing regulatory compliance requirements for preventing accidents in various industries. The advent of new types of materials used in manufacturing by end-users necessitates the use of advanced fatigue testing machines to ensure product durability and safety. Additionally, the growing availability of pre-used variants and rental fatigue testing machines has made these machines more accessible to small and medium-sized enterprises, thereby expanding the market's reach. This trend is expected to continue as industries prioritize safety and quality in their manufacturing processes. Furthermore, technological advancements in fatigue testing machines, such as automated testing and data analysis, are enhancing their efficiency and accuracy, making them indispensable tools for ensuring product reliability and longevity.

What will be the Size of the Market During the Forecast Period?

For More Highlights About this Report, Request Free Sample

Market Dynamic and Customer Landscape

The market encompasses a range of machinery used to evaluate the durability and endurance of materials such as Rubber, Metals, Alloys, Plastic, and others under cyclic loading conditions. This market caters to various industries, including Aerospace, General industrial, Construction, Defense, and Automobile. Three main categories of fatigue testing machines exist: Low-capacity, Mid-capacity, and High-capacity. These machines are essential for testing materials used in Nitinol wire, Titanium, Nickel, and other components. The demand for electric and hybrid vehicles is driving the market growth, as these vehicles require rigorous testing to ensure safety and longevity. Fatigue testing machines are crucial for assessing the performance and reliability of materials under various stress conditions, ensuring the safety and efficiency of numerous applications.

Key Market Driver

Growing regulatory compliance requirements for preventing accidents are notably driving the market growth. Fatigue testing machines play a crucial role in the manufacturing and research sectors, particularly in the testing of materials such as Rubber, Metals, Alloys, Plastics, and Nitinol wire. These machines are essential in various industries, including Aerospace, General industrial, Construction, Defense, and Automobile. In the Aerospace sector, fatigue testing is vital for ensuring the durability and reliability of materials used in Aircraft, spacecraft, and satellites. Midcapacity fatigue tester and Highcapacity fatigue tester are commonly used for testing suspension systems, engine parts, and chassis components in the Automobile industry. The demand for electric and hybrid vehicles is driving the need for advanced fatigue testing machines to ensure the longevity of these complex systems.

In addition, fatigue testing is also used in the Manufacturing sector, Research Institutes, and Laboratories for Materials Science. Dynamic and Static tests are employed to evaluate the fatigue behavior of materials under various loading conditions. The Industrial sector also uses fatigue testing machines for testing materials used in Bicycles, golf clubs, and athletic gear. Titanium, Nickel, and other alloys, as well as composites, are frequently tested using these machines. Thus, such factors are driving the growth of the market during the forecast period.

Significant Market Trends

The advent of new types of materials for manufacturing by end-users is the key trend in the market. Manufacturers are experimenting with new types of materials in manufacturing processes to meet the changing requirements of end-users. For instance, in the automotive and aerospace industries, many new grades of advanced high-strength steel are being used, such as advanced high-strength steel (AHSS) 101. The welding of high strength needs to be done with caution as it is prone to cracks compared with mild steel. The high-strength steel, therefore, requires a higher level of inspection. It increases the requirement for fatigue testing machines to identify issues associated with welding. OEMs are increasingly adopting lightweight materials for the vehicle body, chassis, interior, and other applications. Lightweight materials are one of the top priorities among OEM manufacturers.

Moreover, advanced materials such as carbon fiber composites offer unparalleled strength-to-weight ratios, allowing aircraft manufacturers to shed tons of weight in structural components while maintaining or even improving their integrity. This weight reduction translates directly into fuel efficiency, increased range, and lower emissions for aircraft. However, these revolutionary materials require sophisticated testing approaches to understand their behavior fully under varying conditions. Integrating different advanced materials seamlessly in aircraft demands innovative joining techniques. This has led to the development and testing of advanced adhesives, welding processes, and even laser-based methods to ensure robust and durable connections. This opens opportunities for fatigue testing machine vendors that specialize in evaluating fatigue resistance. These factors will increase the demand for fatigue testing machines, fueling market growth during the forecast period.

Major Market Challenge

The growing availability of pre-used variants and rental fatigue testing machines is the major challenge that affects the growth of the market. Companies operating in the market are focusing on developing fatigue testing machines with improved features. All end-users cannot, however, invest in updated variants of fatigue testing machines frequently. Many end-users also prefer purchasing pre-used fatigue testing machines, which are available at much lower costs compared with new units. End-users can get information regarding the availability of such models through advertisements in printed media. The pre-used variants can also be availed from various online portals, such as Machinio. Increasing end-user inclination toward pre-used models of fatigue testing machines will negatively impact the sales of new units, which will hinder the potential growth of the market in focus during the forecast period.

Moreover, end-users can also avail of fatigue testing machines on a rental basis. By using rented fatigue testing machines, end-users can save additional costs, such as service costs and maintenance costs. Owing to this, they can also save on the initial purchase costs associated with fatigue testing machines. Some of the vendors offering fatigue testing machines on a rental basis are Victor Manufacturing Sdn Bhd and Tailored Test Solutions Ltd. The cost-saving benefits offered by rental equipment may encourage more end-users to avail of such services and negatively impact the sales of new units, which will hinder the growth of the market in focus during the forecast period.

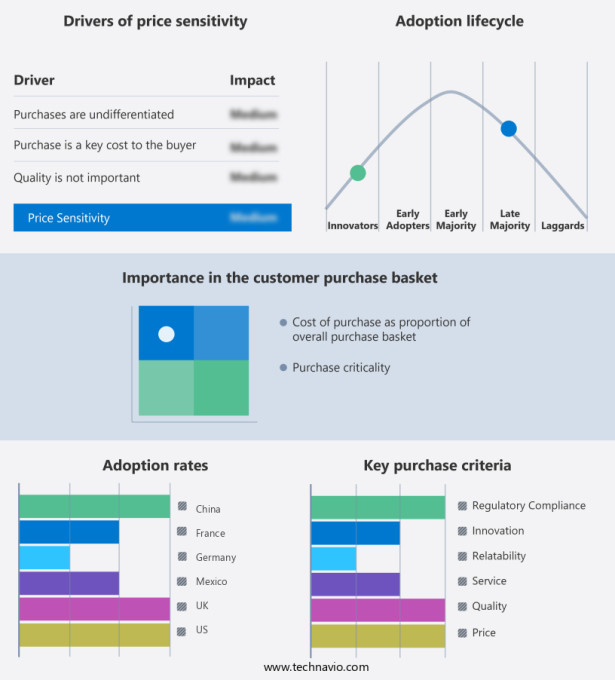

Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

ADMET Inc. - The company offers fatigue testing machine such as eXpert 5900 series electrodynamic testing system for determining the durability of materials and components in tension, compression, or flexure.

The market research and growth report also includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ADMET Inc.

- Aimil Ltd.

- Blue Star Ltd.

- Ducom Instruments

- Ektron Tek Co. Ltd.

- FINE GROUP

- Fine Manufacturing Industries

- Fuel Instruments and Engineers Pvt. Ltd.

- HOVERLABS

- Hydraulic and Engineering Instruments

- Illinois Tool Works Inc.

- Kalpak Instruments and Controls

- Montana Tech Components AG

- Presto Group

- Russenberger Prufmaschinen AG

- S S S Instruments

- SE Test Lab Instruments I Pvt. Ltd.

- Shimadzu Corp.

- Testing lab instruments

- ZwickRoell GmbH and Co. KG

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Market Segmentation

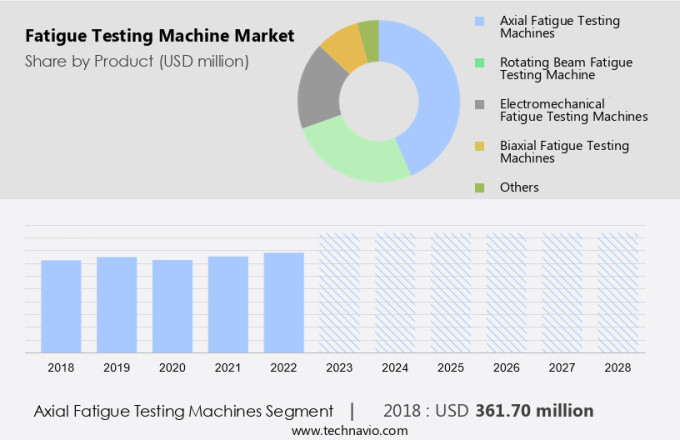

By Product

The Axial fatigue testing machines segment is estimated to witness significant growth during the forecast period. Axial fatigue testing machines are essential machinery used in Materials Science and Manufacturing industries for evaluating the endurance limit of various materials, including Rubber, Metals, Alloys, Plastics, and Composites. These machines apply an axial tensile force that oscillates in a sinusoidal waveform of constant frequency within the elastic range.

Get a glance at the market share of various regions Download the PDF Sample

The axial fatigue testing machines segment was the largest and was valued at USD 361.70 million in 2018. They are primarily utilized for static and dynamic mechanical fatigue tests on components, such as suspension systems, engine parts, chassis components, and alloys used in the Aerospace, Defense, and Automobile industries. Additionally, they find applications in testing materials for Bicycles, golf clubs, athletic gear, and other structural components. The demand for electric and hybrid vehicles is increasing the need for fatigue testing machines in the Automobile sector. Laboratories, Research Institutes, and Industrial Sector rely on these machines for testing materials under various conditions. High-capacity fatigue testers can test large components, while mid-capacity testers cater to smaller components. Nitinol wire, Titanium, Nickel, and other materials undergo fatigue testing using these machines. The market for fatigue testing machines is expanding, with vendors offering advanced features and solutions.

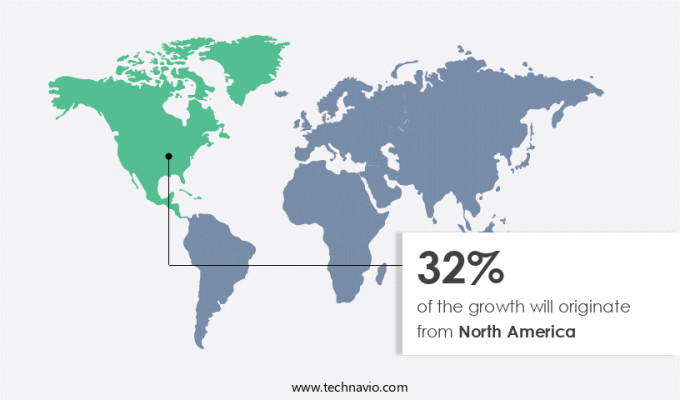

By Region

For more insights on the market share of various regions Download PDF Sample now!

North America is estimated to contribute 32% to the growth of the global market during the forecast period. Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period. Fatigue testing machines play a crucial role in assessing the durability and reliability of various materials, including Rubber, Metals, Alloys, and Plastics, used in diverse industries. These machines are integral to the manufacturing sector, particularly in the production of suspension systems, engine parts, and chassis components for the automobile industry, as well as in the aerospace sector for the testing of Nitinol wire, Titanium, and Nickel used in aircraft, spacecraft, satellites, and other high-performance applications. Midcapacity and high capacity fatigue testers are employed in laboratories, research institutes, and industrial sectors for static and dynamic tests to evaluate the fatigue properties of materials.

Further, the demand for fatigue testing machines is on the rise due to the increasing production of electric and hybrid vehicles, which necessitate rigorous testing to ensure the longevity and safety of their components. Additionally, fatigue testing machines find extensive use in the medical industry for testing implants and other medical devices, as well as in the general industrial, construction, defense, and even in the production of bicycles, golf clubs, and athletic gear. The market for fatigue testing machines is expected to grow significantly due to the increasing emphasis on materials science and the need for improved manufacturing processes.

Segment Overview

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million " for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Product Outlook

- Axial fatigue testing machines

- Rotating beam fatigue testing machine

- Electromechanical fatigue testing machines

- Biaxial fatigue testing machines

- Others

- Application Outlook

- Automotive industry

- Aerospace industry

- Composite industry

- Medical industry

- Others

- Region Outlook

- APAC

- China

- India

- North America

- The U.S.

- Canada

- Europe

- The U.K.

- Germany

- France

- Rest of Europe

- South America

- Brazil

- Argentina

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

- APAC

You may also interested in the below market reports

- Shape Memory Alloy (Sma) Market Analysis North America, APAC, Europe, South America, Middle East and Africa - US, China, Germany, France, Japan - Size and Forecast

- Military Wearable Sensors Market Analysis North America, Europe, APAC, Middle East and Africa, South America - US, China, Germany, France, Russia - Size and Forecast

- Automotive Adaptive Front Lighting System Market Analysis Europe, North America, APAC, South America, Middle East and Africa - US, China, Germany, UK, Japan - Size and Forecast

Market Analyst Overview

The market is experiencing robust growth due to its critical role in assessing material durability across various sectors. Mid-capacity fatigue testers and high-capacity fatigue testers are pivotal in industries such as Aerospace, Defense, Automobile, and General industrial applications. These machines test a wide range of materials, including rubber, metals, alloys, and plastics to ensure reliability. Key materials like nitinol wire, titanium, and nickel are frequently subjected to fatigue tests to verify their performance in suspension systems, engine parts, chassis components, and other critical applications. The demand for electric and hybrid vehicles, alongside advancements in Materials Science, has spurred the need for advanced fatigue testing machines. These machines are integral to manufacturing, construction, and medical laboratories, where static tests and dynamic tests are conducted. Furthermore, the growth in research institutes, aircraft, spacecraft, satellites, bicycles, golf clubs, and athletic gear underscores the expanding market for fatigue testing machinery.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

210 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.69% |

|

Market Growth 2024-2028 |

USD 309 million |

|

Market structure |

Concentrated |

|

YoY growth 2023-2024(%) |

4.41 |

|

Regional analysis |

North America, Europe, APAC, South America, and Middle East and Africa |

|

Performing market contribution |

North America at 32% |

|

Key countries |

US, China, Mexico, Germany, France, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

ADMET Inc., Aimil Ltd., Blue Star Ltd., Ducom Instruments, Ektron Tek Co. Ltd., FINE GROUP, Fine Manufacturing Industries, Fuel Instruments and Engineers Pvt. Ltd., HOVERLABS, Hydraulic and Engineering Instruments, Illinois Tool Works Inc., Kalpak Instruments and Controls, Montana Tech Components AG, Presto Group, Russenberger Prufmaschinen AG, S S S Instruments, SE Test Lab Instruments I Pvt. Ltd., Shimadzu Corp., Testing lab instruments, and ZwickRoell GmbH and Co. KG |

|

Market dynamics |

Parent market analysis, Market Forecasting, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, Market condition analysis for market forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting of the market between 2024 and 2028

- Precise estimation of the size of the market size and its contribution to the parent market

- Accurate predictions about upcoming market trends and analysis and changes in consumer behavior

- Growth of the market industry across Europe, North America, APAC, South America, and Middle East and Africa

- Thorough market growth analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive market analysis and report on the factors that will challenge the market research and growth of market companies