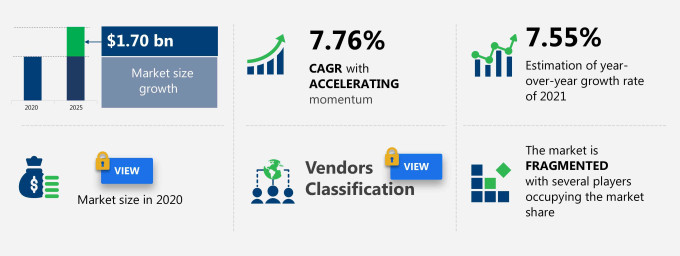

The industrial robot sensors market share is expected to increase by USD 1.70 billion from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 7.76%. This industrial robot sensors market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. The industrial robot sensors market report also offers information on several market vendors, including ATI Industrial Automation, DAIHEN Corp., FANUC Corp., FUTEK Advanced Sensor Technology Inc., Honeywell International Inc., OMRON Corp., OnRobot A/S, Rockwell Automation Inc., Seiko Epson Corp., and Velodyne Lidar Inc. among others. Furthermore, this report extensively covers industrial robot sensors market segmentation by product (vision systems, force/torque sensors, proximity sensors, collision detection sensors, and safety sensors), application (material handling, welding, assembly line, and others), and geography (APAC, Europe, North America, South America, and MEA).

What will the Industrial Robot Sensors Market Size be During the Forecast Period?

Download the Free Report Sample to Unlock the Industrial Robot Sensors Market Size for the Forecast Period and Other Important Statistics

Industrial Robot Sensors Market: Key Drivers, Trends, and Challenges

Based on our research output, there has been a neutral impact on the market growth during and post COVID-19 era. The technological improvements in vision systems is notably driving the industrial robot sensors market growth, although factors such as challenges in delivering high quality at low cost may impede market growth. Industrial robot sensors are a specialized category within industrial sensors, designed to enhance the precision and efficiency of automated manufacturing processes. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the industrial robot sensors industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Industrial Robot Sensors Market Driver

One of the key factors driving the industrial robot sensors market growth is the technological improvements in vision systems. To enhance vision systems and sustain leadership in vision-guided robotics, vendors are consistently working on advancing their product offerings through better technologies. One such technology is visual servoing, which comprises providing feedback with the help of vision sensors to influence the motion of a robot or other machine. It mainly involves three approaches: 3D, hybrid, and image-based visual servoing. The technology eliminated the need for extensive camera calibration and allowed better control of the robot's components. Another major field of innovation and improvement is LiDAR, which is especially used in autonomous mobile robots. The development of technologies will mainly be driven by venture capital investments for software and hardware enhancements. In terms of application, the use of enhanced vision systems will help in applications such as bin-picking. By using LiDAR, the robot employed can have a better view and an enhanced capability in viewing the objects clearly.

Key Industrial Robot Sensors Market Trend

Increase in adoption of safety systems in industrial robots are the major trend influencing the industrial robot sensors market growth. Prominence has been given to cobots due to their multiple safety features and lack of expenditure for safety equipment. The common trade-off for cobots is low speed and payload, unlike traditional industrial robots. However, safety has been a priority even for traditional industrial robots, as most OEMs have designed their own specific safety drives in robot controllers. Traditional robots can also interact with human beings as they comply with ANSI/RIA R15.06-2012 standards. Some of the safety drives are more practical for environments where industrial robots have been incorporated for a longer time. Like cobots, traditional robots are increasingly being augmented with vision systems and sensors to prevent collision and trauma. However, this is an area, which is likely to be explored extensively in the future and include techniques such as fast detection of collisions and force-torque monitoring.

Key Industrial Robot Sensors Market Challenge

Delivering high quality at low cost is one of the key challenges hindering the industrial robot sensors market growth. Robotics engineers, along with system developers, are continuously researching on adding more products that have enhanced quality in their portfolios. However, a major challenge for industrial robot sensors manufacturers has been the size of the industry, which is not large enough to drive the economies of scale. But, economies of scale are essential to bringing down the costs of developing new sensors. A major factor that drives up the cost of sensors is the need for customization to ensure that it delivers the accuracy and reliability, which is expected from a robotic system. The cost of sensors has fallen over the years, especially due to the availability of off-the-shelf varieties of sensors, which are mainly used in industrial automation systems. However, a sensor customized for application-specific robots will be technologically advanced, hence more expensive. The sensors for robots use careful engineering, hand wiring, and expensive components. As the market for industrial robots gains traction, it is essential that suppliers of industrial robot sensors provide easily customizable and affordable robot sensors.

This industrial robot sensors market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the global industrial robot sensors market as a part of the global industrial machinery market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the industrial robot sensors market during the forecast period.

Who are the Major Industrial Robot Sensors Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- ATI Industrial Automation

- DAIHEN Corp.

- FANUC Corp.

- FUTEK Advanced Sensor Technology Inc.

- Honeywell International Inc.

- OMRON Corp.

- OnRobot A/S

- Rockwell Automation Inc.

- Seiko Epson Corp.

- Velodyne Lidar Inc.

This statistical study of the industrial robot sensors market encompasses successful business strategies deployed by the key vendors. The industrial robot sensors market is fragmented and the vendors are deploying growth strategies such as R&D activities for diversified industries to compete in the market.

Product Insights and News

- ATI Industrial Automation - The company offers robotic tool changer which provides the flexibility to automatically change end-effectors or other peripheral tooling.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The industrial robot sensors market forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Industrial Robot Sensors Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the industrial robot sensors market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The report has further elucidated on other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Industrial Robot Sensors Market?

For more insights on the market share of various regions Request for a FREE sample now!

62% of the market’s growth will originate from APAC during the forecast period. China and Japan are the key markets for industrial robot sensors in APAC. Market growth in this region will be slower than the growth of the market in other regions.

Favorable government legislation and investments have facilitated the growth of the manufacturing industry in APAC, thus boosting the development of infrastructure and related industries such as robots and sensors. Thus, the industrial robot sensors market in APAC has grown considerably, making it a preferred manufacturing hub. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

COVID Impact and Recovery Analysis

In the second half of 2020, the lifting of lockdowns in many countries across the region resulted in the resumption of operations in the above-mentioned sectors. Many countries in the region have started COVID-19 vaccination drives, which will have a positive impact on the market. In the long run, after the pandemic is contained, the huge demand for industrial robot sensors from the above-mentioned sectors is expected to contribute to the growth of the market in the region during the forecast period.

What are the Revenue-generating Product Segments in the Industrial Robot Sensors Market?

To gain further insights on the market contribution of various segments Request for a FREE sample

The industrial robot sensors market share growth by the visions systems will be significant during the forecast period. The vision system of the global industrial robot sensors market is expected to grow consistently during the forecast period due to the emergence of industrial robots that can be used for assembling and material handling.

Besides the above-mentioned factors, the post COVID-19 impact has brought forth a slowdown in or fast tracked the demand for the service or product. This report provides an accurate prediction of the contribution of all the segments to the growth of the industrial robot sensors market size and actionable market insights on post COVID-19 impact on each segment.

|

Industrial Robot Sensors Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 7.76% |

|

Market growth 2021-2025 |

USD 1.70 billion |

|

Market structure |

Fragmented |

|

YoY growth (%) |

7.55 |

|

Regional analysis |

APAC, Europe, North America, South America, and MEA |

|

Performing market contribution |

APAC at 62% |

|

Key consumer countries |

China, Japan, and Germany |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

ATI Industrial Automation, DAIHEN Corp., FANUC Corp., FUTEK Advanced Sensor Technology Inc., Honeywell International Inc., OMRON Corp., OnRobot A/S, Rockwell Automation Inc., Seiko Epson Corp., and Velodyne Lidar Inc. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Industrial Robot Sensors Market Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive industrial robot sensors market growth during the next five years

- Precise estimation of the industrial robot sensors market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the industrial robot sensors industry across APAC, Europe, North America, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of industrial robot sensors market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch