Rotary Seals Market Size 2024-2028

The rotary seals market size is forecast to increase by USD 1.68 billion at a CAGR of 4.54% between 2023 and 2028.

- The market is experiencing significant growth, driven primarily by the high demand in the water and wastewater industry. These seals are essential components in various applications, including pumps and compressors, to prevent leakage and ensure efficient operation. The use of superior quality raw materials, such as elastomers and metals, enhances the durability and performance of rotary seals, making them a preferred choice for numerous industries. However, the market is not without challenges. Frequent failures due to wear and tear, contamination, and extreme operating conditions pose significant risks. To mitigate these challenges, market participants are investing in research and development to produce rotary seals with improved resistance to chemicals, temperature, and pressure.

- Additionally, the adoption of advanced manufacturing techniques, such as 3D printing and nanotechnology, offers opportunities for enhanced product performance and cost savings. Companies seeking to capitalize on market opportunities and navigate challenges effectively should focus on innovation, quality, and customer service.

What will be the Size of the Rotary Seals Market during the forecast period?

- The market in the US is experiencing significant growth, driven by the increasing demand for high-performance seals in various power generation applications, particularly in renewable energy sectors. These seals are essential for containing fluids, toxic gases, and preventing contaminants from entering mechanical systems. Rotary seals offer flexible designs, custom profiles, and advanced materials such as ceramic composites and elastomer materials for enhanced corrosion resistance, longevity performance, and wear resistance. In industrial settings, rotary seals are used extensively in oil and gas, hydraulic systems, and chemical processing industries. They ensure lubricant retention, dust protection, and pressure tolerance, contributing to improved system efficiency and reliability.

- Rotary seals come in various types, including mechanical face seals, lip seals, labyrinth seals, and static seals, each catering to specific temperature ranges and fluid compatibility requirements. The market is influenced by regulations, focusing on seal durability, vibration control, and materials science. The shift towards electric vehicles and sustainable energy sources is further expanding the market's scope. Advanced materials like silicon carbide and the development of new production techniques continue to drive innovation in the rotary seals industry. Despite challenges from failures and wear resistance, the market is expected to continue its upward trajectory, offering substantial opportunities for growth.

How is this Rotary Seals Industry segmented?

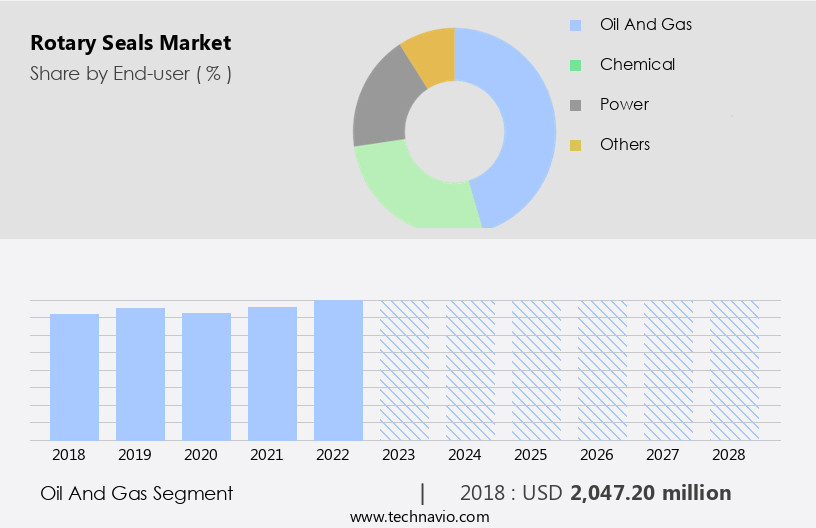

The rotary seals industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Oil and gas

- Chemical

- Power

- Others

- Application

- Automotive

- Industrial Machinery

- Aerospace

- Pumps

- Product Type

- Mechanical Seals

- Lip Seals

- O-Rings

- Radial Shaft Seals

- Material

- Rubber

- PTFE

- Silicone

- Metal

- Geography

- APAC

- China

- India

- Japan

- South Korea

- Europe

- France

- Germany

- Italy

- Spain

- UK

- North America

- US

- Canada

- Mexico

- Middle East and Africa

- UAE

- South America

- Brazil

- APAC

By End-user Insights

The oil and gas segment is estimated to witness significant growth during the forecast period.

Rotary seals play a crucial role in various industries, particularly in mechanical systems used in oil and gas, medical equipment, and renewable energy. In the oil and gas sector, these seals are essential in applications such as main oil line pumps, booster pumps, and crude export pumps due to the high usage of caustic, corrosive, abrasive, and acidic fluids and toxic gases. The expanding oil and gas production facilities and pipeline networks are driving the demand for rotary seals, which are engineered to ensure chemical compatibility and high-pressure resistance. Similarly, in the medical equipment industry, application-specific seals, including V-ring seals and lip seals, are employed to maintain the sterility and hygiene standards required in healthcare settings.

In the field of semiconductors, non-metallic rotary seals are utilized for their excellent wear resistance and chemical compatibility. The renewable energy sector, including wind and hydropower, relies on rotary seals for their energy efficiency and ability to operate under high temperatures and pressures. In the realm of electric vehicles, smart seals with real-time monitoring capabilities are gaining popularity for their role in enhancing power transmission and extending battery life. In the realm of instrumentation, rotary seals made of advanced materials like PTFE, ceramic composites, thermoplastics, and thermoplastic elastomers are used to ensure precise measurement and control in various industrial settings.

These materials offer superior properties such as high temperature tolerance, flexibility, and chemical resistance. In mechanical systems, rotary seals are used in gearboxes, pumps, and turbines to prevent leakage and contamination. The increasing industrialization and manufacturing activities necessitate the use of high-performance seals that can withstand the rigors of heavy-duty machinery and motors. In the chemical industry, rotary seals are designed to meet specific requirements, such as wear resistance, chemical compatibility, and regulatory standards. These seals are used in various applications, including wastewater treatment, mixers, and hydraulic systems. In the marine industry, rotary seals are used to ensure the safe and efficient operation of various mechanical systems, including pumps, valves, and propellers.

In the power sector, rotary seals are employed in turbines and generators to maintain optimal performance and efficiency. In summary, the rotary seal market is driven by the increasing demand for equipment in various industries, including oil and gas, medical, semiconductors, renewable energy, and chemical. The market is characterized by the use of advanced materials, smart technologies, and application-specific designs to meet the unique requirements of various industries. The demand for rotary seals is expected to continue growing as industries invest in new technologies and expand their operations.

Get a glance at the market report of share of various segments Request Free Sample

The Oil and gas segment was valued at USD 2.05 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 45% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market encompasses a range of sealing solutions for various industries, including Medical Equipment, Semiconductors, Renewable Energy, and Industrial Settings. Application-specific seals, such as V-ring seals and lip seals, are widely used in Mechanical Systems, Pumps, and Machinery. Non-metallic seals, including those made of Polyurethanes and Thermoplastics, offer advantages in terms of chemical compatibility and wear resistance. Advanced materials, such as PTFE, Ceramic composites, and Spring less designs, are increasingly utilized for high-performance applications, including in High pressure systems, Turbines, and Gearboxes. Smart technologies, such as IoT-enabled seals and Mechanical face seals, enable real-time monitoring and improved efficiency in various sectors.

In the Medical Equipment industry, application-specific seals ensure the purity of fluids and protect against contaminants, while meeting hygiene regulations. In the Chemical industry, seals must withstand toxic gases and corrosive substances, necessitating advanced materials and engineering systems. In the Oil and Gas sector, seals must operate under extreme temperatures and pressures, requiring high-performance materials and manufacturing techniques. Increasing industrialization and manufacturing activities drive the demand for seals in various industries. Material combinations, such as PTFE lip seals with silicon carbide, offer enhanced wear resistance and chemical compatibility. Smart seals, including those with flexible inner lips and temperature tolerance, improve efficiency and reliability in various applications.

Regulations and regulatory standards play a significant role in the market, with an emphasis on safety, efficiency, and environmental considerations. In the Aerospace and Automotive industries, seals must meet stringent safety and performance requirements, while in the Marine industry, seals must withstand harsh environmental conditions. In summary, the market is driven by the need for efficient, reliable, and advanced sealing solutions in various industries, including Medical Equipment, Semiconductors, Renewable Energy, and Industrial Settings. Material combinations, manufacturing techniques, and smart technologies are key trends shaping the market. Regulations and safety considerations are critical factors influencing market growth.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Rotary Seals Industry?

- High demand for rotary seals in the water and wastewater industry is the key driver of the market.

- Rotary seals have gained significance in various industries beyond oil and gas and manufacturing. Wastewater treatment plants are emerging as a notable end-user sector due to the increasing number of such facilities. These plants utilize rotary seals for sealing agitators and pumps. The global water and wastewater equipment market is poised for growth during the forecast period, driven by factors such as population growth, expanding manufacturing activities, and rising oil and gas production.

- Water is an essential resource for numerous industries, including food and beverage, pharmaceuticals, and pulp and paper. As water usage increases in these sectors, the demand for reliable sealing solutions like rotary seals is expected to escalate.

What are the market trends shaping the Rotary Seals Industry?

- Use of superior quality raw materials is the upcoming market trend.

- Rotary seals are essential components engineered to perform effectively in challenging environmental conditions and temperature extremes, ranging from -32°F to 1832°F. To meet these demands, superior quality raw materials, including high-grade steel alloys, are utilized. Aluminum, Monel, and copper are employed as metal covers, while expanded graphite functions as a filler material. In the manufacturing of non-metallic rotary seals, high-quality materials such as rubber, silicone, fluoroelastomer, aramid fiber, carbon fiber, cellulose fiber, glass fiber, and mineral fiber are preferred.

- These materials offer superior tensile strength, durability, stability, and resistance to chemicals and acids, thereby increasing their deployment across various industries and extending the operational life of seals.

What challenges does the Rotary Seals Industry face during its growth?

- Frequent failures with rotary seals is a key challenge affecting the industry growth.

- Rotary seals play a crucial role in the proper functioning of pumps by acting as a barrier between the pump's chamber and the external environment. These seals prevent the leakage of fluids and ensure the pump's efficiency. However, their failure can significantly impact the pump's performance and overall operation. Some reasons for rotary seal failure include running the pump dry and exposing the seal to thermal shock. Running a pump dry can accelerate seal wear and tear, potentially causing irreversible damage.

- Thermal shock, which occurs when the seal is exposed to a sudden temperature change, can shatter the seal in less than 30 seconds. To mitigate these risks, it is essential to select the appropriate rotary seal for the specific application and ensure its error-free installation. Failure to do so can result in costly repairs and downtime.

Exclusive Customer Landscape

The rotary seals market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the rotary seals market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, rotary seals market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

SKF Group (Sweden) - The company specializes in manufacturing and supplying advanced rotary seal solutions, including Matrix seals for pumps, gearboxes, and conveyors. These seals enhance system efficiency and durability, ensuring optimal performance in various industrial applications. By utilizing cutting-edge materials and engineering techniques, our products cater to diverse industries and applications, providing reliable and cost-effective solutions for our clients.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- SKF Group (Sweden)

- Trelleborg AB (Sweden)

- Freudenberg Sealing Technologies (Germany)

- Parker Hannifin Corporation (United States)

- John Crane (United States)

- EagleBurgmann (Germany)

- Flowserve Corporation (United States)

- Garlock Sealing Technologies (United States)

- James Walker Group Ltd. (United Kingdom)

- Bal Seal Engineering Inc. (United States)

- Chesterton Company (United States)

- Daemar Inc. (Canada)

- KACO GmbH + Co. KG (Germany)

- NOK Corporation (Japan)

- Simrit (Germany)

- Seals Eastern Inc. (United States)

- Max Spare Ltd. (India)

- Klinger Ltd. (United Kingdom)

- Seal & Design Inc. (United States)

- Technetics Group (United States)

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The rotary seal market encompasses a diverse range of sealing solutions designed to prevent the leakage of fluids, gases, and contaminants in various industrial applications. These seals play a crucial role in ensuring the efficient operation and longevity of mechanical systems, machinery, and equipment across numerous industries. Application-specific seals, such as V-ring seals and lip seals, are commonly utilized in industries like semiconductors, renewable energy, and aerospace and automotive. In the semiconductor industry, seals made of non-metallic materials, such as polyurethanes and thermoplastics, are preferred due to their chemical compatibility and ability to withstand high temperatures. In the renewable energy sector, rotary seals are essential components in centrifuges, pumps, and turbines, ensuring the efficient transfer and containment of fluids and gases.

Seals made of advanced materials, such as ceramic composites and silicon carbide, offer superior wear resistance and temperature tolerance, making them suitable for high-performance applications. The increasing industrialization and production techniques have led to the development of innovative sealing solutions. For instance, spring less seals and labyrinth seals have gained popularity due to their energy efficiency and ability to handle high pressures. In addition, the integration of smart technologies, such as real-time monitoring and IoT-enabled seals, has enabled predictive maintenance and improved system performance. Mechanical seals, including lip seals and mechanical face seals, are widely used in industries like oil and gas, chemical, and wastewater treatment.

These seals offer superior containment and leakage prevention, ensuring the safe and efficient operation of machinery and equipment. Regulations and hygiene standards play a significant role in the design and application of rotary seals. For instance, in the pharmaceutical and food industries, seals made of elastomers and PTFE are preferred due to their chemical compatibility and ability to meet stringent hygiene regulations. In the aerospace and automotive industries, seals made of metallic materials and advanced materials, such as ceramic composites and silicon carbide, are used to ensure the safe and efficient operation of machinery and equipment under extreme conditions. The rotary seal market is driven by the increasing demand for efficient and reliable sealing solutions in various industries.

Factors such as increasing industrialization, manufacturing activities, and regulatory standards are expected to fuel the growth of the market. In , the rotary seal market is a dynamic and diverse industry, with a wide range of sealing solutions catering to various applications and industries. The development of innovative materials, manufacturing techniques, and smart technologies is expected to drive the growth of the market and offer new opportunities for manufacturers and suppliers.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

151 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.54% |

|

Market growth 2024-2028 |

USD 1682.9 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.24 |

|

Key countries |

US, China, Japan, Germany, France, Spain, Canada, India, South Korea, France, Japan, Italy, Brazil, UAE, UK, Spain, Rest of World (ROW), and Mexico |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Rotary Seals Market Research and Growth Report?

- CAGR of the Rotary Seals industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the rotary seals market growth of industry companies

We can help! Our analysts can customize this rotary seals market research report to meet your requirements.