Large Circular Knitting Machine Market Size 2024-2028

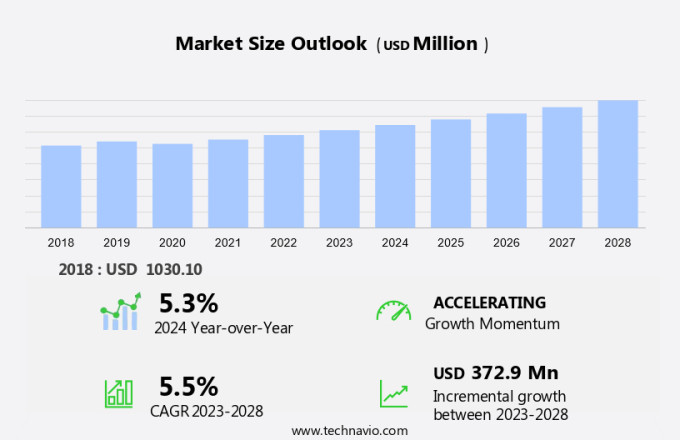

The large circular knitting machine market size is forecast to increase by USD 372.9 million, at a CAGR of 5.5% between 2023 and 2028.

- The market is driven by the growing popularity of knitting as a health-promoting activity and the increasing collaborations between textile companies and fashion brands. Knitting, as a fiber craft, has gained significant traction due to its numerous health benefits, including stress relief, improved focus, and the creation of unique, personalized clothing items. This trend is fueling the demand for large circular knitting machines, which enable mass production of high-quality knitted fabrics. However, the high cost of these machines poses a significant challenge for small and medium-sized enterprises (SMEs) looking to enter the market. The high initial investment required for purchasing and maintaining these machines can act as a barrier to entry, limiting the market access for potential players.

- To capitalize on the market opportunities, companies must focus on offering financing solutions, leasing options, or partnerships to help SMEs overcome financial hurdle. Additionally, investing in research and development to create more cost-effective and energy-efficient machines could provide a competitive edge in the market.

What will be the Size of the Large Circular Knitting Machine Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2018-2022 and forecasts 2024-2028 - in the full report.

Request Free Sample

The market is characterized by its continuous evolution and dynamic nature, with ongoing advancements in production efficiency, knitting innovation, and technological developments shaping the industry. Pattern programming and needle selection play crucial roles in optimizing knitting processes, while safety standards and environmental impact are increasingly prioritized. Knitting diameter and stitch density are essential factors in determining fabric weight and construction, which in turn influence knitting technology and operator training requirements. Machine automation and knitting software have revolutionized the knitting process, enabling increased machine uptime and productivity. Fabric weight, rib knitting, and fabric construction vary widely across sectors, from apparel production to textile manufacturing, requiring machine capacity and reliability to meet diverse industry demands.

Knitting technology advances, such as jacquard knitting and 3D knitting, continue to push the boundaries of knitwear trends and design possibilities. Cost optimization and sustainability practices are essential considerations for manufacturers, with energy consumption and yarn waste reduction becoming key areas of focus. Machine maintenance, technical support, and spare parts availability are essential for ensuring machine reliability and minimizing downtime. Yarn properties, such as tension control and quality, are critical factors in producing high-quality fabrics. The knitting industry remains a dynamic and innovative field, with ongoing research and development driving progress in knitting technology, design, and manufacturing processes.

How is this Large Circular Knitting Machine Industry segmented?

The large circular knitting machine industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Apparel and fashion

- Technical textiles

- Home textiles

- Technology

- Automatic or computerized circular knitting machines

- Manual or mechanical circular knitting machines

- Smart circular knitting machines

- Geography

- North America

- US

- Europe

- France

- Germany

- Spain

- UK

- APAC

- China

- India

- Japan

- Vietnam

- South America

- Brazil

- Rest of World (ROW)

- North America

.

By Application Insights

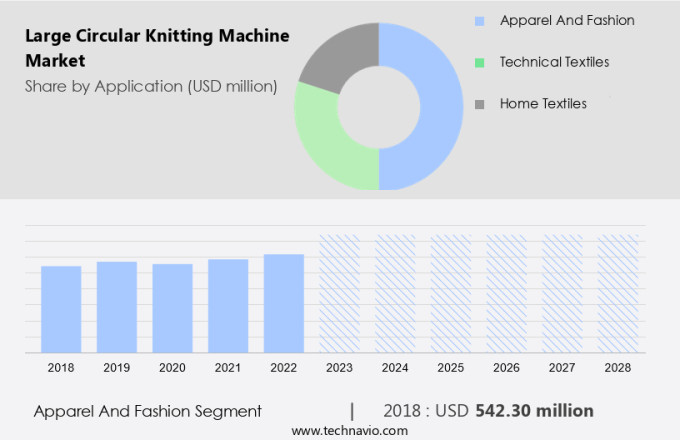

The apparel and fashion segment is estimated to witness significant growth during the forecast period.

The market experiences significant growth, driven primarily by the apparel and fashion industry's increasing demand for high-quality knitted garments. These machines produce a wide array of fabrics for various applications, including casual wear, sportswear, activewear, sleepwear, and workwear. Manufacturers focus on knitting innovation to meet consumer preferences for eco-friendly and comfortable fabrics, such as those made from 100% cotton, organic blends, and sustainable materials. Sustainability practices are increasingly emphasized, with producers adopting fair trade cotton and ethical production methods. Knitting technology advancements include pattern programming, operator training, machine automation, needle selection, yarn tension control, and knitting software.

Additionally, yarn feed systems, quality control, and cylinder diameter are crucial factors influencing machine performance. The market further prioritizes energy consumption reduction, machine uptime optimization, and spare parts availability to ensure machine reliability and cost efficiency. The textile manufacturing sector benefits from these advancements, leading to improved fabric quality and production volume. Knitting technology trends include 3D knitting, automated knitting, and jacquard knitting, among others. The knitwear industry's focus on knitting designs, fashion trends, and knitting process improvements continues to drive market growth.

The Apparel and fashion segment was valued at USD 542.30 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

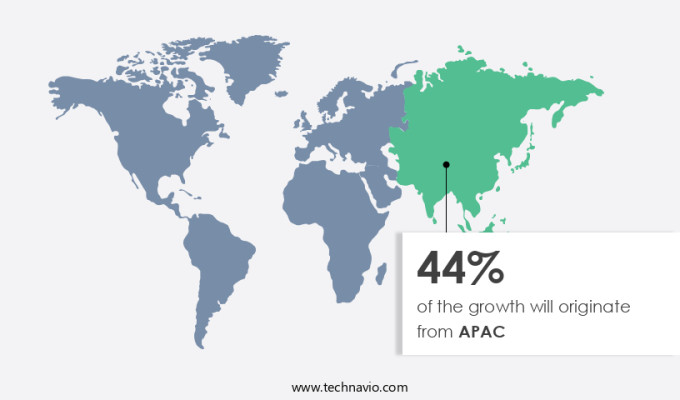

APAC is estimated to contribute 44% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market is experiencing significant growth, with a focus on production efficiency and knitting innovation. In the Asia-Pacific region, countries such as China, India, Japan, South Korea, and Australia are driving this market due to their rich textile heritage and increasing demand for sustainable, technologically advanced products. At the ITMA Asia + CITME event in Shanghai, China, in November 2023, key innovations in circular knitting machinery will be showcased. Groz-Beckert, a global leader in industrial machine needles and precision parts, will exhibit its contributions to various textile sectors, including knitting. Pattern programming, safety standards, environmental impact, and knitting diameter are essential considerations in the market.

Stitch density, knitting technology, operator training, and machine automation are also critical factors. Fabric weight, rib knitting, fabric construction, knitting defects, jacquard knitting, production volume, needle selection, yarn tension control, knitting software, yarn feed system, quality control, sustainability practices, industrial knitting, knitting gauge, fiber types, double knitting, machine uptime, fancy knitting, cost optimization, knitting output, knitting process, knitwear trends, 3D knitting, automated knitting, cylinder diameter, yarn waste, textile trends, apparel production, machine maintenance, technical support, yarn properties, downtime management, and knitwear industry are all integral components of the market. Groz-Beckert's presence at ITMA Asia + CITME underscores the importance of these factors in the market.

The company's commitment to advancing knitting technology and sustainability practices aligns with market trends and consumer preferences. The market is expected to continue evolving, with a focus on energy consumption, circular knitting, spare parts availability, and knitting designs.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Large Circular Knitting Machine Industry?

- The significant health benefits associated with knitting and other fiber crafts serve as the primary market motivator.

- The market is experiencing growth due to the rising trend of knitting and other fiber crafts for health and wellness benefits. Knitting, crocheting, and related activities have gained popularity, particularly among younger demographics and men, as people recognize their therapeutic and cognitive advantages. Research indicates that these crafts can induce relaxation, alleviating stress, anxiety, and even physical pain, offering an alternative form of therapy. Furthermore, engaging in knitting can enhance focus and concentration, thereby improving problem-solving and analytical skills. Knitting machine manufacturers respond to this trend by offering machines with advanced features, such as high yarn quality, machine capacity, machine reliability, and knitting designs that cater to various fashion trends.

- Energy consumption and spare parts availability are also essential considerations for textile manufacturers seeking efficient and reliable circular knitting machines. In conclusion, the market is poised for growth as more people discover the benefits of knitting and related crafts for both personal well-being and professional applications.

What are the market trends shaping the Large Circular Knitting Machine Industry?

- Professional trend: Growing collaborations are increasingly prevalent in today's market. Maintain a knowledgeable stance on this topic: Collaborative partnerships are becoming a mandatory aspect in business success.

- The market is experiencing significant advancements through strategic collaborations between manufacturers and technology providers. One notable instance is the partnership between Santoni and Groz-Beckert in April 2024. This alliance led to the creation of the INNOTAS self-cleaning knitting system, designed to address the growing demand for sustainability and production efficiency in the textile sector. The collaboration resulted in the development of the SAN DUO needle and SNK DUO-OL sinker, which work together to form a self-cleaning mechanism that minimizes yarn soiling. Moreover, knitting innovation continues to drive market growth, with pattern programming and machine automation becoming increasingly essential.

- Safety standards and environmental impact are also crucial considerations, with manufacturers focusing on developing machines with higher knitting diameter, stitch density, and fabric weight capabilities. Rib knitting and fabric construction are also areas of significant interest, as manufacturers seek to address knitting defects and improve overall fabric quality. Operator training and knitting technology are other critical factors shaping the market. As the industry evolves, machine operators require specialized skills to effectively utilize the advanced features of modern knitting machines. Machine automation and digitalization are also transforming the landscape, with manufacturers investing in technology to streamline production processes and improve overall efficiency.

- In conclusion, the market is witnessing a period of innovation and growth, driven by collaborations between manufacturers and technology providers, a focus on sustainability and production efficiency, and the development of advanced knitting technologies. These trends are expected to continue shaping the market in the coming years.

What challenges does the Large Circular Knitting Machine Industry face during its growth?

- The high cost of large circular knitting machines poses a significant challenge to the growth of the industry, as these expensive pieces of equipment are essential for producing high-quality textiles in large quantities.

- The market encompasses advanced technologies that enable industrial-scale production of various textile products. Jacquard knitting, double knitting, and fancy knitting are among the techniques utilized in this sector. Production volume in this market is influenced by several factors, including needle selection, yarn tension control, knitting software, yarn feed system, and quality control. One of the significant challenges is the high cost of these machines. For instance, an Interlock Circular Knitting Machine can cost up to USD 1.9 million, while a Heavy Duty Industrial Circular Knitting Machine is priced around USD 200,000. More specialized machines, such as single-phase latch needle computerized circular knitting machines, can cost approximately USD330,000.

- These substantial upfront investments can deter smaller textile manufacturers or those in emerging markets with limited financial resources. Sustainability practices and cost optimization are crucial considerations in the market. Machine uptime, knitting gauge, and fiber types are essential factors that influence both production efficiency and product quality. As the industry evolves, machine manufacturers and textile producers must focus on innovation and technology integration to maintain competitiveness.

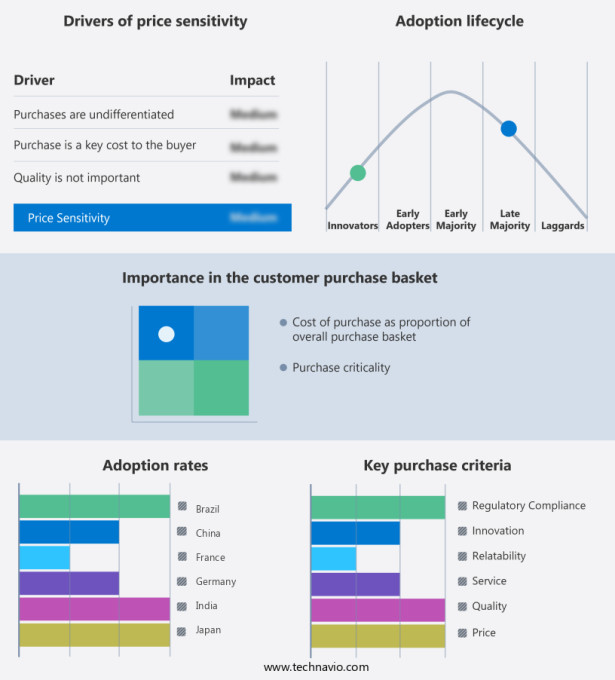

Exclusive Customer Landscape

The large circular knitting machine market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the large circular knitting machine market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, large circular knitting machine market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Fujian Baiyuan Machinery Co Ltd - The company specializes in providing advanced circular knitting machinery, encompassing single jersey, double jersey, and jacquard models.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Fujian Baiyuan Machinery Co Ltd

- FUJIAN TAIFAN INDUSTRIAL Co Ltd.

- FUKUHARA INDUSTRIAL and TRADING Co Ltd

- karl mayer stoll textilmaschinenfabrik Gmbh

- Kauo Heng Precision Machinery Industrial Co Ltd.

- KEUMYONG MACHINERY Co Ltd.

- Lisky Technology Co Ltd.

- Mayer & Cie. GmbH & Co. KG

- ORIZIO Srl

- Santoni Spa

- SHIMA SEIKI MFG Ltd.

- Tayu Machine

- Terrot Textilmaschinen GmbH

- United Texmac Pte Ltd.

- Vanguard Pailung

- Wellknit Textile Technology Co ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Large Circular Knitting Machine Market

- In February 2023, Shandong Yueyue Textile Machinery Co., Ltd. introduced its new series of large circular knitting machines, featuring advanced technology and increased production capacity. These machines, which can produce fabrics up to 54 inches in width, are designed to cater to the growing demand for larger-sized textiles in the fashion industry (Shandong Yueyue Press Release, 2023).

- In April 2024, Italian textile machinery manufacturer, Ratti SpA, announced a strategic partnership with Chinese circular knitting machine manufacturer, Zhejiang Wintom Machinery Co., Ltd. This collaboration aims to bring innovative circular knitting technology to the Chinese market and expand Ratti's global presence (Ratti SpA Press Release, 2024).

- In June 2024, German textile machinery manufacturer, Groz-Beckert, completed the acquisition of a significant stake in Japanese circular knitting machine manufacturer, Toyo Jidoshokki Co., Ltd. This investment will enable Groz-Beckert to expand its product portfolio and strengthen its position in the Asian market (Groz-Beckert Press Release, 2024).

- In November 2025, the European Union granted a significant grant to a consortium of textile machinery manufacturers, including Italian firm, Marzoli, to develop a new generation of energy-efficient circular knitting machines. This initiative is part of the EU's Horizon 2020 research and innovation program and aims to reduce the carbon footprint of the textile industry (European Commission Press Release, 2025).

Research Analyst Overview

- The market encompasses advanced technologies and innovations shaping apparel production. Machine capacity and automation are key trends, with technical support ensuring optimal fabric construction and quality control. Downtime management is crucial for production efficiency, while machine maintenance minimizes knitting defects. Knitting process and design are intertwined, with knitting gauge influencing fabric weight and stitch density. Fashion and textile trends impact knitting patterns, from plain to fancy, and energy consumption is a critical consideration for industrial knitting. Automated knitting, double knitting, and 3D knitting technologies are revolutionizing the knitwear industry. Yarn quality and tension control are essential for producing high-quality fabrics, and operator training enhances overall performance.

- Fiber types and knitting output are also significant factors, with knitting software facilitating design and innovation. Knitting speed and yarn waste management are ongoing concerns for manufacturers, as they strive to minimize costs and maximize efficiency. Knitting technology continues to evolve, driving the industry forward.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Large Circular Knitting Machine Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

203 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.5% |

|

Market growth 2024-2028 |

USD 372.9 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

5.3 |

|

Key countries |

US, China, Japan, India, Vietnam, Germany, UK, France, Spain, and Brazil |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Large Circular Knitting Machine Market Research and Growth Report?

- CAGR of the Large Circular Knitting Machine industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the large circular knitting machine market growth of industry companies

We can help! Our analysts can customize this large circular knitting machine market research report to meet your requirements.