Thermoplastic Micro Molding Market Size 2024-2028

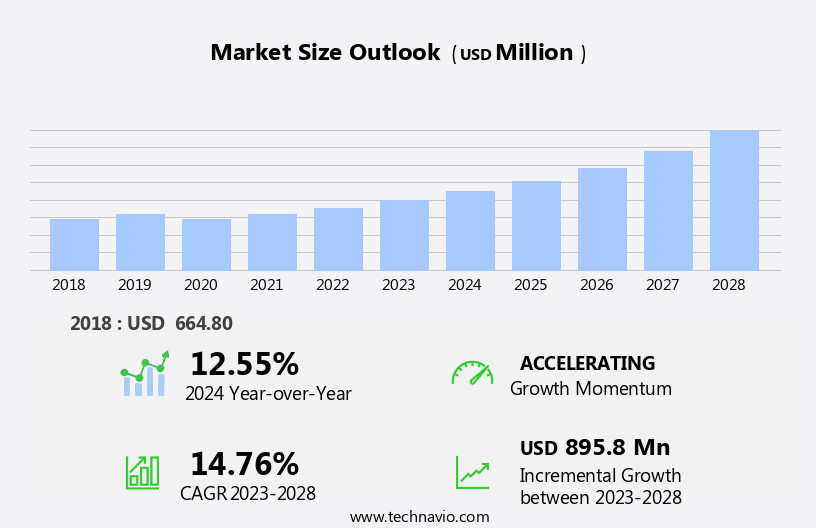

The thermoplastic micro molding market size is forecast to increase by USD 895.8 million at a CAGR of 14.76% between 2023 and 2028.

What will be the Size of the Thermoplastic Micro Molding Market during the forecast period?

How is this Thermoplastic Micro Molding Industry segmented?

The thermoplastic micro molding industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Medical

- Electronics

- Automotive

- Packaging

- Others

- Geography

- APAC

- China

- Japan

- South Korea

- Europe

- Germany

- France

- North America

- US

- South America

- Middle East and Africa

- APAC

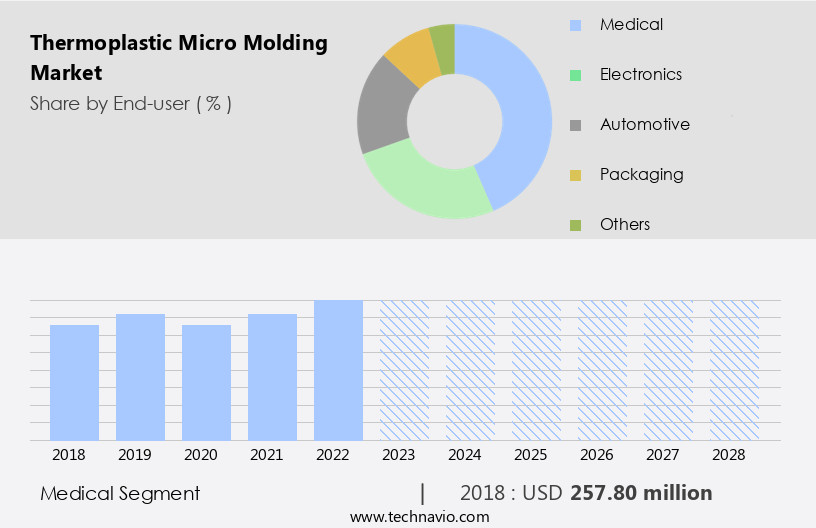

By End-user Insights

The medical segment is estimated to witness significant growth during the forecast period.Thermoplastic micro molding plays a crucial role in various industries, including automobiles, medical, healthcare, micro-optics, electronics, and aerospace technologies. In the automotive sector, it is used for manufacturing micro gear wheels, interior parts, and enabling vehicle weight reduction. The medical industry leverages thermoplastic micro molding for producing precise, biocompatible components for hearing aids, implantable medical devices, and microfluidic devices. In the electronics sector, thermoplastic micro molding is employed for manufacturing high-precision, consistent, and repeatable electronic components such as SIM card connectors, pin connectors, single, multi-mode ferrules, and coax plugs. The materials commonly used In thermoplastic micro molding include Polyetheretherketone (PEEK), Liquid crystal polymer (LCP), Polyoxymethylene (POM), Polycarbonate (PC), Polyamide (PA), Polyethylene (PE), and others.

This cost-effective solution is suitable for high-volume production and is increasingly being adopted In the manufacturing of wearable devices, miniature electronics, smartwatches, fitness trackers, and sensors. The accuracy, consistency, and repeatability offered by thermoplastic micro molding make it an ideal choice for various applications In the medical, electronics, and aerospace industries.

Get a glance at the market report of share of various segments Request Free Sample

The Medical segment was valued at USD 257.80 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 47% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market is experiencing significant growth in APAC, driven by the automotive, medical, and electronics industries. The automotive sector's expansion in APAC, particularly in countries like India, Indonesia, Thailand, and Vietnam, is fueled by increasing demand. This growth is propelling the need for thermoplastic micro molding in automotive manufacturing, with China, Japan, and India being major contributors. The healthcare industry in APAC is thriving due to rising income levels, population growth, disease prevalence, and heightened health awareness. The electronics sector's growth In the region is attributed to the increasing demand for miniaturized components in wearable devices, smartwatches, fitness trackers, implantable medical devices, microfluidic devices, and more.

Thermoplastic micro molding is a cost-effective solution for manufacturing precise, consistent, and repeatable plastic components with tight tolerances for these industries. Key thermoplastic materials used include Polyetheretherketone (PEEK), Liquid crystal polymer (LCP), Polyoxymethylene (POM), Polycarbonate (PC), Polyamide (PA), Polyethylene (PE), and others. The manufacturing process involves injecting thermoplastic material into a mold cavity under specific temperature and pressure conditions. The resulting components are used in various applications, including micro gear wheels, interior parts, vehicle weight reduction, medical devices, aerospace technologies, and more. The thermoplastic micro molding process offers advantages such as accuracy, consistency, and repeatability, making it an essential technology for the electronics, aerospace, and medical industries.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Thermoplastic Micro Molding Industry?

- Strong demand from automotive industry is the key driver of the market.

- The market is experiencing significant growth due to increasing demand from the automotive industry. In this sector, thermoplastic micro molding is increasingly utilized for interior and exterior applications, replacing traditional materials like metal and other engineering thermoplastics. The advantages of thermoplastic micro molding, such as UV protection, optimal balance of stiffness, cold temperature impact resistance, and low thermal expansion, make it an ideal choice for automobile manufacturing. Moreover, rising disposable incomes, particularly in emerging economies, are driving the demand for vehicles and attracting first-time buyers. The expanding middle class populations in China, India, Brazil, and South Korea, with increasing household earnings, are expected to fuel the growth of the automotive industry.

- Consequently, The market is poised for continued expansion, providing numerous opportunities for market participants.

What are the market trends shaping the Thermoplastic Micro Molding Industry?

- Increasing opportunities in APAC is the upcoming market trend.

- Thermoplastic micro molding holds significance In the automotive industry for manufacturing various components such as doors, acoustic panels, instrument panels, anti-vibration panels, seats, and airbags. The material's desirable properties, including elasticity, strength, chemical resistance, and high-temperature performance, make it an ideal choice for automotive applications. The Asia Pacific (APAC) region is projected to witness the fastest growth In the market. Factors contributing to this growth include the expanding automotive industry and increasing purchasing power of consumers in APAC. China, in particular, is a major contributor to the automotive market's growth due to strong government support and favorable tax incentives.

- In conclusion, the automotive industry's growth in APAC, driven by rising consumer purchasing power and government initiatives, is expected to fuel the demand for thermoplastic micro molding In the coming years.

What challenges does the Thermoplastic Micro Molding Industry face during its growth?

- Increasing disparity between demand and supply is a key challenge affecting the industry growth.

- The market experienced significant disparities between supply and demand in 2020. Notably, Latin America is a leading region exhibiting these disparities, with a demand exceeding 6.8 million metric tons. This trend is primarily driven by the expanding middle-class population In the region. Furthermore, India and China are anticipated to contribute to the global deficit In thermoplastic micro molding supply and demand In the forthcoming years, with India projected to have a deficit of approximately 3 million metric tons. These market dynamics highlight the growing demand for thermoplastic micro molding products, particularly in emerging economies.

Exclusive Customer Landscape

The thermoplastic micro molding market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the thermoplastic micro molding market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, thermoplastic micro molding market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

ACCU Mold LLC - The company specializes In thermoplastic micro molding solutions, ideal for intricate applications such as diffractive optics and micro lenses. This advanced manufacturing process ensures precision and consistency in product design, enhancing search engine visibility for our clients In the research and development sector. Our offerings cater to various industries, aligning with the company's commitment to innovation and quality.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ACCU Mold LLC

- Advanced Plastiform Inc.

- American Precision Products

- EPTAM Precision

- Isometric Micro Molding Inc.

- Makuta Inc.

- MTD Micro Molding

- Natech Plastics Inc.

- PRECIKAM Inc.

- Rapidwerks Inc.

- Scientific Molding Corp. Ltd.

- Sovrin Plastics

- Springboard Manufacturing

- STAMM AG

- Star Rapid

- Veejay Plastic Injection Molding Co.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Thermoplastic micro molding is a manufacturing process that produces intricately detailed plastic components with high precision and accuracy. This technique is widely used in various industries, including automobiles, medical, healthcare, micro-optics, electronic industries, and aerospace technologies. The process involves injecting molten thermoplastic material into a mold cavity under specific temperature and pressure conditions. Thermoplastic micro molding offers several advantages over traditional manufacturing methods. It enables the production of complex geometries with tight tolerances, making it an ideal choice for creating micro gear wheels, interior parts, and other intricate components. The use of thermoplastic materials also results in lighter weight parts, contributing to vehicle weight reduction and increased fuel efficiency In the automotive industry.

In the medical industry, thermoplastic micro molding plays a crucial role In the manufacturing of various medical devices. These include hearing aids, implantable medical devices, microfluidic devices, and surgical instruments. The biocompatibility of thermoplastic materials ensures that these components are safe for use in patient care. The electronics sector is another major consumer of thermoplastic micro molded components. These components are used in various applications, including electronic components, sim card connectors, pin connectors, single-mode and multi-mode ferrules, coax plugs, and miniature electronics. The miniaturization trend in consumer goods such as wearable devices, smartwatches, fitness trackers, and smartphones is driving the demand for thermoplastic micro molded components.

The aerospace industry also benefits from thermoplastic micro molding due to its ability to produce high-precision components for aerospace technologies. These components include sensors, telecommunications equipment, and microelectromechanical systems. The cost-effectiveness of thermoplastic micro molding makes it a preferred choice for high-volume production. The thermoplastic materials commonly used in micro molding include polyetheretherketone (PEEK), liquid crystal polymer (LCP), polyoxymethylene (POM), polycarbonate (PC), polyamide (PA), polyethylene (PE), and others. The choice of material depends on the specific application requirements, such as biocompatibility, wear resistance, and temperature resistance. The manufacturing process of thermoplastic micro molding requires precise temperature and pressure control to ensure accuracy, consistency, and repeatability.

The process involves several stages, including material preparation, molding, cooling, and ejection. The use of advanced automation and control systems ensures that the process is efficient and cost-effective. In conclusion, thermoplastic micro molding is a versatile manufacturing process that offers several advantages over traditional manufacturing methods. It is widely used in various industries, including automotive, medical, healthcare, electronics, and aerospace, to produce intricately detailed components with high precision and accuracy. The use of thermoplastic materials enables the production of lightweight parts, contributing to vehicle weight reduction and increased fuel efficiency. The miniaturization trend in consumer goods is driving the demand for thermoplastic micro molded components, making it a growing market with significant potential for innovation and growth.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

137 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 14.76% |

|

Market growth 2024-2028 |

USD 895.8 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

12.55 |

|

Key countries |

US, China, Japan, Germany, France, and South Korea |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Thermoplastic Micro Molding Market Research and Growth Report?

- CAGR of the Thermoplastic Micro Molding industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the thermoplastic micro molding market growth of industry companies

We can help! Our analysts can customize this thermoplastic micro molding market research report to meet your requirements.