Concrete Fibers Market Size 2025-2029

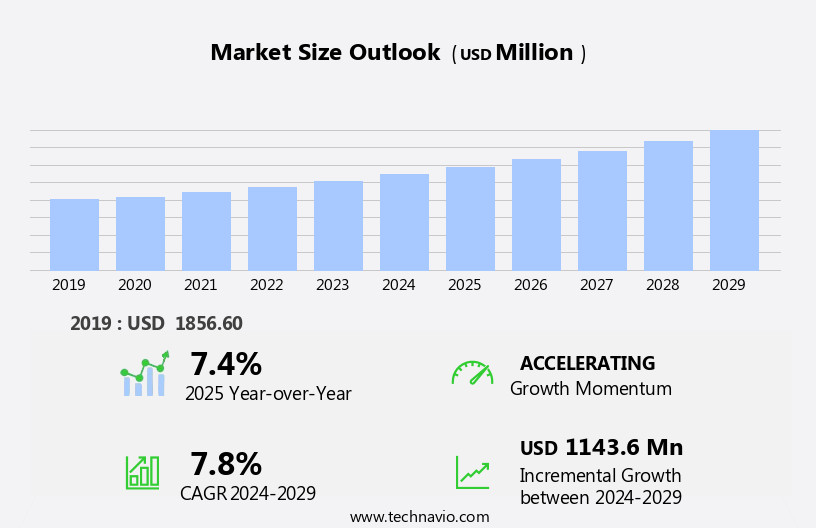

The concrete fibers market size is forecast to increase by USD 1.14 billion at a CAGR of 7.8% between 2024 and 2029.

- The market is experiencing significant growth due to the increasing demand for durable construction materials in various end-use industries, particularly in infrastructure and residential sectors. Technological advancements in fiber engineering have led to the production of high-performance fibers, enhancing the strength, durability, and resilience of concrete structures. However, the high initial cost of fiber-reinforced concrete remains a significant challenge for market growth. Innovations in material science have led to the development of advanced lightweight materials, such as aerated concrete, lightweight steel, and engineered wood, which offer superior insulation properties and reduced construction time. This cost barrier can be addressed through economies of scale, technological innovations, and government incentives to promote the adoption of high-performance building materials. Companies seeking to capitalize on market opportunities should focus on developing cost-effective production methods and expanding their product offerings to cater to diverse end-use industries. The market is expected to witness steady growth in the coming years, with key trends including the increasing use of prefabricated and modular construction, growing demand for net-zero energy buildings, and the integration of smart technologies in construction materials.

- Effective collaboration with industry stakeholders, including construction companies and regulatory bodies, can also help in navigating the challenges and driving market growth. Overall, the market presents significant opportunities for growth, driven by the demand for durable and high-performance construction materials, coupled with technological advancements and strategic partnerships.

What will be the Size of the Concrete Fibers Market during the forecast period?

- The market encompasses various sectors, including performance modeling, quality assurance, and sustainable concrete solutions. Low-carbon concrete and fiber-reinforced polymer (FRP) are gaining traction due to their environmental benefits and improved structural performance. Supply chain management and concrete admixtures, such as fiber distribution networks and smart fibers, ensure efficient production and enhance concrete properties. Computer-aided design (CAD) and concrete simulation enable precise modeling and analysis of fiber-reinforced composites. Recycled concrete and concrete testing are essential for quality control and adherence to standards and regulations. Self-healing concrete and fiber logistics are key components of the circular economy, reducing waste and improving sustainability. One such innovation is the use of bio-based composites, derived from renewable energy sources, in vacuum forming and thermoforming processes. In the marine industry, lightweight materials like recycled plastics are gaining popularity for their fuel efficiency and durability.

- Concrete inspection, structural analysis, and non-destructive testing employ advanced technologies like fiber-optic sensors and digital twin technology to assess concrete structures' integrity. Concrete casting, pouring, and curing processes are optimized through the use of air-entraining agents and 3D printing concrete. Bio-based fibers and water-reducing agents contribute to eco-friendly concrete additives. Robotic concrete construction and building codes ensure efficient and safe construction processes. In addition, the wind energy industry is another significant market for lightweight construction materials, with the use of lightweight steel framing and composite materials in wind turbines. The market continues to evolve with innovations in concrete design, such as self-healing concrete and the integration of digital technologies.

How is this Concrete Fibers Industry segmented?

The concrete fibers industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

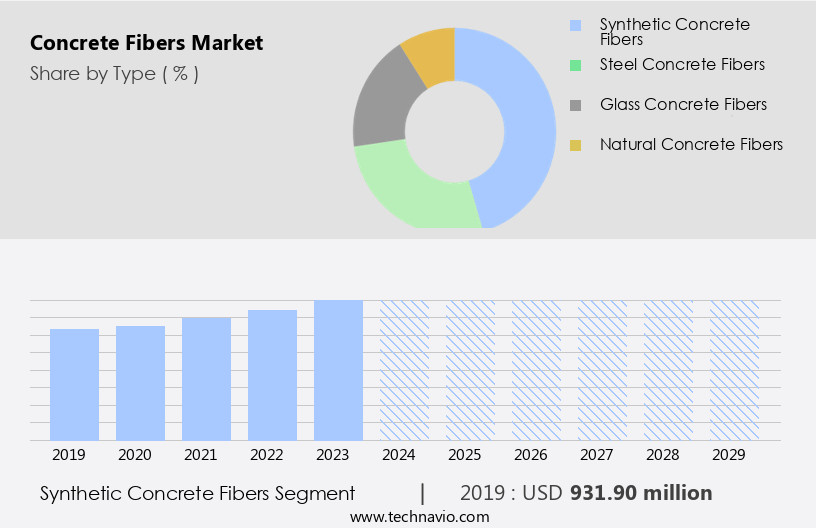

- Type

- Synthetic concrete fibers

- Steel concrete fibers

- Glass concrete fibers

- Natural concrete fibers

- Application

- Transportation

- Infrastructure

- Mining

- Others

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Middle East and Africa

- South America

- North America

By Type Insights

The synthetic concrete fibers segment is estimated to witness significant growth during the forecast period. Synthetic concrete fibers, crafted from materials like polypropylene, polyester, nylon, and polyethylene, play a crucial role in reinforcing concrete and enhancing its mechanical properties. These fibers offer versatility, making them a preferred choice across various construction sectors. Their lightweight nature, corrosion resistance, and chemical stability contribute to their widespread adoption. Micro-synthetic fibers, typically shorter than 19 mm, primarily focus on controlling plastic shrinkage cracking and bolstering early-age concrete performance. In contrast, macro-synthetic fibers, with lengths exceeding 19 mm, are engineered to amplify post-crack load-bearing capacity, toughness, and durability, making them ideal for structural applications, such as slabs-on-grade, tunnel linings, precast elements, industrial flooring, and shotcrete.

Fiber types vary, including polypropylene, glass, carbon, basalt, and steel fibers. Each fiber type offers unique benefits, such as enhanced fire resistance, thermal resistance, alkali resistance, and impact resistance. Fiber certification, fiber volume fraction, and fiber treatment are essential considerations for ensuring fiber quality and performance. Fiber processing techniques, such as fiber blending, fiber distribution, and fiber testing, are crucial to maintaining consistent fiber quality and ensuring optimal fiber dispersion in concrete mix design. The adoption of electric arc furnace technology is also playing a crucial role in enhancing steel production efficiency and sustainability. High-performance concrete, self-consolidating concrete, and fiber-reinforced concrete are some applications that significantly benefit from synthetic fiber reinforcement. Green building initiatives have led to increased demand for eco-friendly materials, including synthetic fibers.

Fiber-reinforced concrete is a sustainable construction solution that offers enhanced durability and reduced material usage. Infrastructure rehabilitation, concrete repair, and concrete restoration projects also rely on synthetic fibers for crack control and structural strengthening, contributing to the market's growth.

Get a glance at the market report of share of various segments Request Free Sample

The Synthetic concrete fibers segment was valued at USD 931.90 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

North America is estimated to contribute 32% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in North America experiences substantial growth due to significant investments in construction and infrastructure projects. Factors such as large-scale expenditures and legislative initiatives, like the Infrastructure Investment and Jobs Act (IIJA), aiming to modernize and expand infrastructure, drive the demand for concrete fibers in the region. In 2023, US construction spending reached an impressive USD 1.6 trillion, covering residential, non-residential, and infrastructure projects. This massive investment necessitates the use of durable and high-performance construction materials, including concrete fibers. These fibers contribute to enhancing the structural integrity and longevity of buildings and infrastructure, making them essential components in large-scale projects.

Concrete fibers offer various benefits, such as improved shear strength, environmental impact reduction, fatigue resistance, and fire resistance. They also contribute to the production of lightweight concrete, which is increasingly popular in residential and commercial construction. Fiber length, diameter, and dispersion play crucial roles in fiber performance, while certification ensures fiber quality. Manufacturers employ various fiber processing techniques to produce macro and micro synthetic fibers, including carbon, glass, steel, basalt, and polypropylene fibers. Net-zero energy buildings, resilient infrastructure, and smart building technologies are becoming the norm, driving the demand for innovative, lightweight construction materials. Fiber treatment and fiber blending further enhance their properties, such as tensile strength, compressive strength, flexural strength, impact resistance, alkali resistance, and corrosion resistance.

The use of eco-friendly materials and sustainable construction practices also influence market trends. In industrial and civil engineering applications, concrete fibers play a vital role in structural strengthening, crack control, and seismic resistance. Concrete repair and infrastructure rehabilitation projects also benefit from the use of these fibers. Fiber testing and fiber characterization are essential for ensuring consistent fiber quality and performance in concrete mix design.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Concrete Fibers Industry?

- Rising demand for durable construction materials is the key driver of the market. The market experiences growth due to the escalating demand for durable construction materials. With urbanization progressing at a rapid pace and infrastructure aging, there is a pressing need for materials capable of enduring harsh environmental conditions, mechanical stress, and prolonged wear. Conventional concrete, despite its widespread usage, is susceptible to issues like cracking, shrinkage, and structural deterioration over time. In response, there is a heightened emphasis on fiber-reinforced concrete, which boasts enhanced strength, durability, and resistance to cracks. This enhancement is achieved by integrating fibers derived from steel, synthetic polymers, glass, or natural materials into the concrete mix. As a result, fiber-reinforced concrete becomes more resilient and suitable for high-performance construction projects.

What are the market trends shaping the Concrete Fibers Industry?

- Technological advancements in fiber engineering is the upcoming market trend. The market is experiencing significant growth due to technological advancements in fiber engineering. Manufacturers are investing heavily in the development of advanced fiber systems to meet the increasing demand for stronger, more durable, and application-specific concrete solutions. One of the most notable innovations is the emergence of hybrid fiber systems, which combine different types of fibers such as steel and synthetic. These systems offer improved crack control at both micro and macro levels, enhanced post-crack load-carrying capacity, and better toughness and impact resistance. This makes them ideal for complex infrastructure applications. The use of hybrid fiber systems allows concrete to better withstand extreme conditions, such as temperature changes and heavy loads, resulting in longer-lasting and more reliable structures. These advancements are driving the growth of the market, providing opportunities for manufacturers to offer innovative solutions to their customers.

What challenges does the Concrete Fibers Industry face during its growth?

- High initial cost of fiber-reinforced concrete is a key challenge affecting the industry growth. The adoption of fiber-reinforced concrete (FRC) in the construction industry is influenced by several factors. While the benefits, including reduced maintenance, enhanced durability, and lower lifecycle costs, are well-documented, the high initial cost of concrete fibers remains a significant barrier. The cost varies depending on the fiber type and application. For instance, steel fibers, commonly used in industrial flooring and tunnel linings, range from USD 1.00 to USD 1.50 per pound, with typical usage rates between 30 to 100 pounds per cubic yard of concrete. This adds an additional cost of USD30 to USD 150 or more per cubic yard compared to conventional concrete. Despite these challenges, the long-term advantages of FRC make it an attractive option for infrastructure and commercial projects. The construction industry continues to explore ways to mitigate the high initial investment and increase the affordability of FRC.

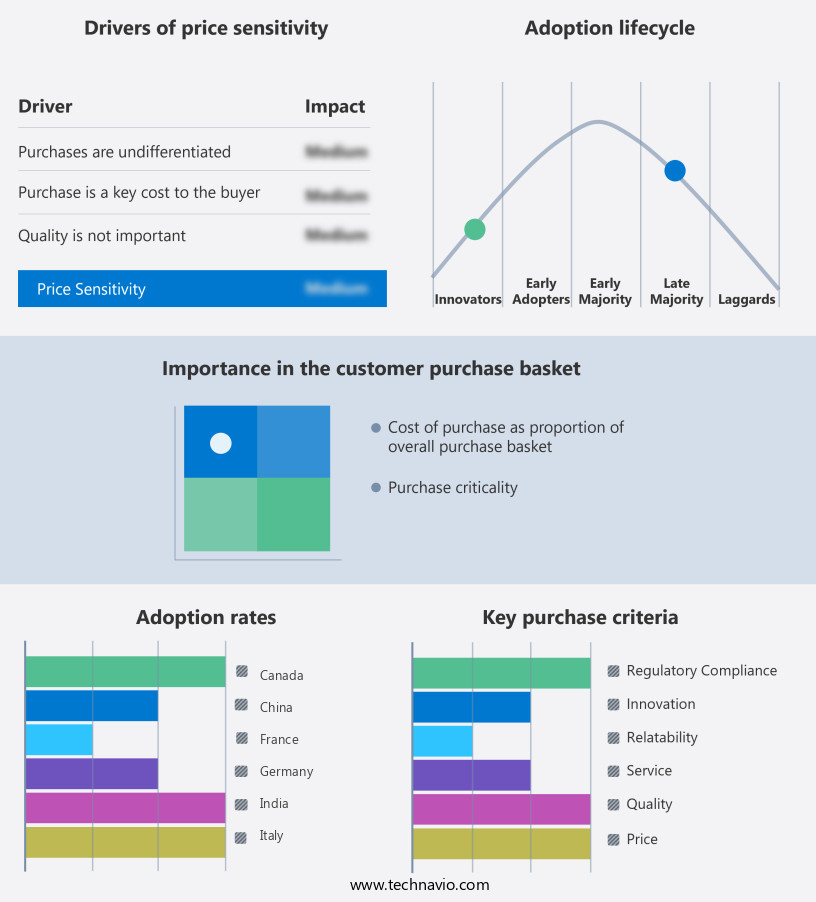

Exclusive Customer Landscape

The concrete fibers market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the concrete fibers market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, concrete fibers market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

ABC Polymer Industries LLC - The company offers FiberForce, its line of high-performance concrete fibers, enhancing infrastructure durability and resilience.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABC Polymer Industries LLC

- BarChip Pty Ltd.

- BASF SE

- CEMEX SAB de CV

- Crafco, Inc

- EPC Engineering and Technologies GmbH

- Fibercon International Inc

- FORTA Corp

- Fosroc International Ltd.

- Heidelberg Materials Australia Group Pty Ltd

- NV Bekaert SA

- Nycon

- Owens Corning

- Ozinga Bros Inc

- Sika AG

- The Euclid Chemical Co.

- W. R. Grace and Co.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The concrete industry continues to evolve, with fiber reinforcement playing an increasingly significant role in enhancing the properties of concrete structures. Fiber reinforcement, which includes carbon, glass, basalt, and synthetic fibers, among others, offers several advantages such as shear strength enhancement, durability improvement, and crack control. One of the primary benefits of fiber reinforcement is the increase in shear strength, which is crucial in structures subjected to heavy loads or lateral forces. The addition of fibers to concrete mix design improves its resistance to shear stress, thereby increasing the overall structural integrity. Moreover, fiber reinforcement contributes to the environmental sustainability of concrete structures through the use of eco-friendly materials. The production and processing of fibers can be optimized to reduce the carbon footprint, making fiber-reinforced concrete a viable option for green building and sustainable construction projects. Fiber length and diameter are essential factors in determining the performance of fiber reinforcement. Longer fibers provide better bond strength and improve the overall tensile and flexural strength of the concrete. Similarly, smaller fiber diameters lead to better fiber dispersion, ensuring uniform distribution throughout the concrete mix. Fiber certification plays a vital role in ensuring the quality and consistency of fiber reinforcement. Proper certification ensures that the fibers meet specific standards for strength, durability, and other performance characteristics.

This, in turn, enhances the reliability and safety of fiber-reinforced concrete structures. Fiber-reinforced concrete is gaining popularity in various sectors, including residential, commercial, and industrial construction. Its lightweight nature makes it an ideal choice for structures requiring reduced weight, such as precast concrete and self-consolidating concrete. Additionally, fiber reinforcement is essential in infrastructure rehabilitation, concrete repair, and structural strengthening, including seismic resistance and fire resistance. The use of fiber reinforcement also offers several benefits in high-performance concrete applications. It improves the compressive strength, thermal resistance, and alkali resistance of concrete, making it suitable for various applications, such as structural concrete and decorative concrete. Fiber manufacturing techniques continue to evolve, with advancements in fiber processing and treatment leading to improved fiber quality control and fiber distribution. These advancements contribute to the overall performance and reliability of fiber-reinforced concrete structures. Fiber reinforcement plays a crucial role in enhancing the properties and performance of concrete structures. Its benefits include increased shear strength, durability, and crack control, as well as improved environmental sustainability and eco-friendliness. The use of fiber reinforcement is gaining popularity across various sectors, and advancements in fiber manufacturing and processing continue to drive innovation and improvements in the industry.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

217 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 7.8% |

|

Market growth 2025-2029 |

USD 1.14 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

7.4 |

|

Key countries |

US, China, UK, Germany, India, Canada, France, South Korea, Japan, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Concrete Fibers Market Research and Growth Report?

- CAGR of the Concrete Fibers industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the concrete fibers market growth of industry companies

We can help! Our analysts can customize this concrete fibers market research report to meet your requirements.