Industrial Boiler Market Size 2025-2029

The industrial boiler market size is forecast to increase by USD 3.2 billion at a CAGR of 3.6% between 2024 and 2029.

- The market is witnessing significant growth, driven by the increasing popularity of hybrid boilers that offer energy efficiency and reduced emissions. This shift towards more sustainable energy solutions is further bolstered by the global trend towards renewable energy sources, such as solar and wind, which is leading to an increase in the adoption of electric boilers. However, regulatory hurdles impact adoption, with stringent emissions regulations necessitating costly upgrades and compliance measures. Additionally, supply chain inconsistencies, including raw material availability and price volatility, temper growth potential.

- Additionally, there is a global shift toward solar and wind energy, which is leading to an increased demand for boilers that can effectively integrate with these renewable energy sources. Companies seeking to capitalize on market opportunities must navigate these challenges effectively by investing in research and development for advanced technologies and fostering strong supplier relationships. By doing so, they can differentiate themselves in the market and meet the evolving energy demands of industries.

What will be the Size of the Industrial Boiler Market during the forecast period?

- The market in the US is experiencing significant activity and trends, driven by the need for improved boiler performance, safety, and emissions reduction. Boiler replacement and installation continue to be key focus areas, with a growing emphasis on boiler codes, standards, and certification to ensure safety and compliance with regulations. Boiler combustion optimization and automation systems are increasingly adopted to enhance efficiency and reduce emissions, particularly in power generation applications. Renewable energy sources, such as biomass, are gaining traction in the market, leading to an increased demand for biomass boilers and boiler water treatment solutions. Boiler inspections, maintenance programs, and monitoring are essential for ensuring optimal boiler operation and longevity.

- Fuels used in industrial boilers include oil, coal, and natural gas. The boiler industry focuses on advancements that improve efficiency, reliability, and sustainability across its entire boiler life cycle, from boiler installation and boiler commissioning to boiler repair and boiler life extension. Innovative practices such as boiler optimization, supported by modern boiler control systems and boiler automation systems, ensure seamless operations and enhanced functionality. Continuous boiler monitoring enables real-time tracking, while tools like boiler data analytics, boiler modeling, and boiler simulation allow detailed boiler performance analysis to identify areas for improvement. Efforts toward boiler emissions reduction and boiler efficiency improvement are key in meeting environmental standards. Adherence to boiler standards and boiler regulations compliance ensures safety and legal conformity. Boiler certification and boiler training programs empower operators with necessary skills, while boiler maintenance programs guarantee longevity. Industry-wide boiler innovation continues to push boundaries to optimize operations for diverse applications, ensuring long-term sustainability and efficiency.

How is this Industrial Boiler Industry segmented?

The industrial boiler industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

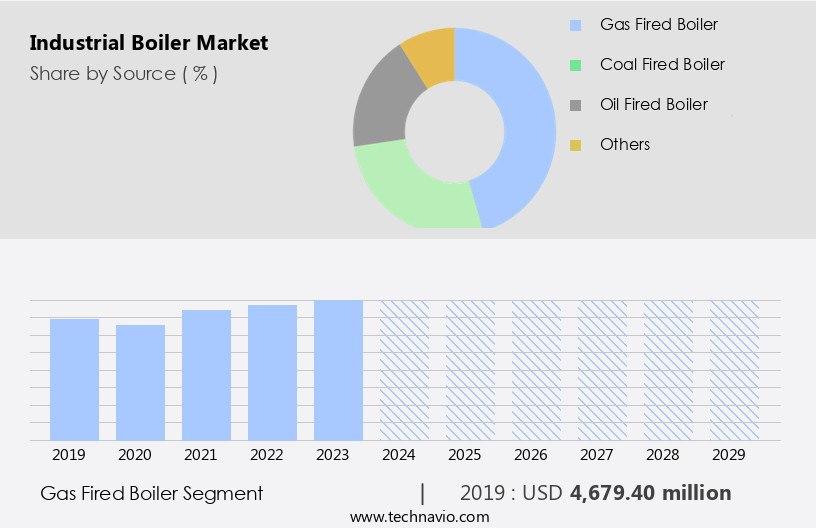

- Source

- Gas fired boiler

- Coal fired boiler

- Oil fired boiler

- Others

- End-user

- Chemicals and petrochemicals

- Food processing

- Paper and pulp

- Power generation

- Others

- Type

- Fire-tube boilers

- Water-tube boilers

- Power Rating

- 10-150 BHP

- 51-300 BHP

- 301-600 BHP

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Source Insights

The gas fired boiler segment is estimated to witness significant growth during the forecast period.

Industrial boilers play a crucial role in various commercial applications, including process heating, power generation, and water heating in industries such as textile mills, food processing, and data centers. Natural gas, an affordable and effective fuel, is widely used in industrial boilers due to its efficiency and lower operating costs compared to other non-renewable resources. According to the US Energy Information Administration (EIA), natural gas-fired combined-cycle plants had the highest capacity utilization percentage among fossil fuels in 2024. This trend is expected to continue, with the capacity utilization percentage of natural gas reaching approximately 80% by 2030.

Boiler safety and emissions control are significant considerations in the market. Regulations, such as Low Nox and Boiler MACT, mandate strict emissions standards for industrial boilers. Boiler components, including economizers, reheaters, superheaters, and blowdown systems, are designed to improve efficiency and reduce emissions. Boiler maintenance and upgrades are essential to ensure optimal performance and longevity. Boiler design and efficiency are critical factors in the market. Condensing boilers, for instance, have higher efficiency levels due to their ability to capture heat from the exhaust gases. Modulating boilers offer improved energy efficiency by adjusting output based on demand.

In the refinery and petrochemical industries, boilers are used to process crude oil and produce chemicals. In the food processing sector, they are employed for cooking, sterilization, and pasteurization. In the pulp & paper industry, they are used for pulping, washing, and cooking. In the primary metal industry, they are used for smelting and melting metals. Boilers are also used in power generation, where they convert fuel into steam to power turbines. In the textile industry, they are used for dyeing and finishing textiles. In the FMCG sector, they are used for producing packaging materials. Boiler rules and regulations mandate the use of materials that can withstand high temperatures and pressures without deformation, stress corrosion, welding issues, or hydrogen embrittlement.

Power generation and large-scale industrial processes require high-capacity boilers, while commercial applications typically require smaller boilers. Boiler inspections and maintenance are essential to ensure safe and efficient operation. Boiler temperature control is crucial to maintain optimal performance and prevent corrosion. The market is driven by the need for efficient and cost-effective water and process heating solutions. Natural gas is a popular fuel due to its affordability and efficiency. Regulations, boiler design, and efficiency are critical factors in the market, along with boiler capacity and maintenance. Renewable energy sources and energy efficiency are emerging trends in the market.

The Gas fired boiler segment was valued at USD 4.68 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 43% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in APAC is experiencing significant growth due to expanding capacities in sectors such as food and beverage, pulp and paper, oil and gas, power generation, steel, and textiles. With approximately 60% of the world's population residing in APAC, the demand for processed food and personal care products is increasing, particularly in developing countries like China, India, Indonesia, Pakistan, Bangladesh, and Vietnam. Urbanization and rising disposable incomes are driving this trend. Additionally, investments in infrastructure, including rail and road networks and modern trade, are improving supply chain efficiency. Boiler components, such as drums, pressure vessels, and accessories, are in high demand for these industries.

High-pressure boilers, condensing boilers, and steam boilers are popular choices for process heating applications. Boiler safety, emissions control, and energy efficiency are key considerations. Boiler design, insulation, and water treatment are essential for optimal performance and longevity. Boiler capacity, fuel consumption, and upgrades are also significant factors. Renewable energy sources, such as biomass and gas, are gaining popularity for boiler applications. Boiler inspections, maintenance, and automation are crucial for ensuring boiler efficiency and reliability. Boiler corrosion and blowdown are common challenges that require effective solutions. The market is dynamic, with ongoing advancements in boiler technology and evolving industry requirements.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Industrial Boiler market drivers leading to the rise in the adoption of Industry?

- The increasing preference for hybrid boilers, characterized by their energy efficiency and cost-effectiveness, is the primary factor fueling market growth in this sector. Hybrid industrial boilers represent an innovative heating solution for energy-intensive industries, such as textile mills and food processing, by combining conventional fuel sources with renewable energy. This integration offers improved efficiency and cost savings, making it an attractive option for businesses. The environmental benefits of hybrid boilers, including reduced carbon emissions and sustainability, align with industry efforts to minimize their carbon footprint. The retirement of coal-fired power plants further fuels the demand for these systems. For instance, Japan Thermal Engineering Company's hybrid boilers can switch between gas and biomass fuel based on availability. Additionally, the higher efficiency rate of hybrid boilers compared to traditional boilers translates into potential cost savings for end-users.

- Boiler design advancements focus on enhancing boiler efficiency, addressing boiler corrosion, and implementing emissions control systems. Low-pressure boilers and hot water boilers are popular choices for industries due to their versatility and adaptability to various process heating applications. Boiler maintenance remains a critical aspect of ensuring optimal performance and longevity, with oil boilers requiring regular inspections and insulation to maintain efficiency.

What are the Industrial Boiler market trends shaping the Industry?

- The rising preference for electric boilers signifies a notable market trend in the heating industry. This shift towards electric boilers is driven by their increasing popularity and efficiency. The market encompasses various types of boilers, including gas, steam, and biomass boilers, used for power generation and heating applications. Gas boilers run on fossil fuels, while steam boilers generate steam for industrial processes. Biomass boilers, on the other hand, utilize renewable energy sources, such as wood chips or agricultural waste, to produce heat. Boiler capacity and temperature are crucial factors influencing the market's growth. Boiler inspections and water treatment are essential to maintain boiler components, including boiler tubes, and ensure their optimal performance. The shift towards low nox emissions and renewable energy sources is driving the demand for advanced boiler technologies.

- Technological advancements in boiler design and manufacturing have led to increased efficiency and reduced emissions, making them more attractive to industries. The global electricity industry's evolution, with decreasing costs and improving reliability, is expanding the application scope of electric steam boilers in industrial processes. As electricity becomes more affordable and accessible, the demand for electric boilers is expected to grow, offering significant opportunities for market participants.

How does Industrial Boiler market faces challenges face during its growth?

- The global transition towards renewable energy sources, particularly solar and wind power, poses a significant challenge yet an exciting opportunity for industry growth. Industrial boilers play a crucial role in various industries, with power generation accounting for a significant portion of the global market revenue. Power boilers, due to their larger size and higher energy requirements, command a higher average selling price than industrial boilers used in sectors like food and beverage, pulp and paper, and textiles. The shift towards renewable energy sources, particularly in developed countries, has led to a decline in the usage of fossil fuel-based power plants as baseload capacity providers. Instead, these plants are now being used to meet peak electricity demand during hours when renewable energy sources fall short.

- Boiler controls, fuel consumption, and energy efficiency are key considerations in the market. Boiler upgrades, retrofits, and the adoption of modulating boilers and boiler automation are trends driving market growth. Fired boilers, coal boilers, and boiler blowdown are common types of industrial boilers, while boiler superheaters enhance the efficiency of the heating process.

Exclusive Customer Landscape

The industrial boiler market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the industrial boiler market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, industrial boiler market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Alfa Laval AB - The company offers industrial boilers such as Aalborg 3 Pass, Aalborg HPNC and Alfa Laval Micro.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Alfa Laval AB

- Andritz AG

- Babcock and Wilcox Enterprises Inc.

- Bharat Heavy Electricals Ltd.

- Byworth Boilers Ltd.

- Cheema Boilers Ltd.

- Cochran Ltd.

- Dongfang Electric Corp. Ltd.

- Forbes Marshall Pvt. Ltd.

- Gammon Engineers and Contractors Pvt. Ltd.

- Harbin Electric Corp.

- IHI Corp.

- John Wood Group PLC

- Mitsubishi Heavy Industries Ltd.

- Parker Boiler Co.

- Rentech Boilers Systems Inc.

- Robert Bosch GmbH

- Siemens AG

- The Cleaver Brooks Co. Inc.

- Thermax Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Industrial Boiler Market

- In February 2023, ABB, a leading technology provider, announced the launch of its new digital offering, ABB Ability⢠Power Generation Services for Industrial Boilers. This solution aims to optimize boiler performance, reduce downtime, and enhance efficiency for industrial customers (ABB Press Release, 2023).

- In March 2024, Siemens Energy and Mitsubishi Heavy Industries, Ltd. (MHI) signed a Memorandum of Understanding (MoU) to collaborate on the development and sales of low-emission industrial boilers. The partnership combines Siemens Energy's expertise in gas turbines and MHI's knowledge in boiler technology, targeting the growing demand for decarbonization in power generation (Siemens Energy Press Release, 2024).

- In May 2025, Kawasaki Heavy Industries Ltd. secured a major order from Saudi Aramco to supply two large-scale industrial boilers for the Marjan Oil Field Expansion Project. The deal, worth approximately USD200 million, underscores Kawasaki's strong presence in the Middle East market and its ability to deliver large-scale projects (Reuters, 2025).

- In October 2025, the European Union (EU) approved the European Industrial Emissions Directive (IED) amendment, which includes stricter emission limits for industrial installations, including boilers. The new regulations aim to further reduce greenhouse gas emissions and improve air quality across Europe (European Commission Press Release, 2025).

Research Analyst Overview

Industrial boilers play a pivotal role in various industries, powering processes that span from power generation and manufacturing to food processing and textile production. The market for industrial boilers is characterized by ongoing dynamics and evolving patterns, shaped by a multitude of factors. Boiler refractory, an essential component of industrial boilers, safeguards the boiler's interior from the harsh conditions of high temperatures and corrosive environments. Boiler regulations, established to ensure safety and efficiency, continue to evolve, driving the market for boiler upgrades and retrofits. Boiler drums, a critical part of the boiler system, undergo constant pressure fluctuations, necessitating robust designs and materials to maintain their integrity.

Boiler pressure, a crucial factor in boiler efficiency, is meticulously monitored and controlled to optimize performance. Boiler accessories, such as economizers and reheaters, enhance the overall efficiency of industrial boilers, contributing to significant fuel savings. High-pressure boilers, a subset of the market, cater to industries requiring intense heat and high steam pressures. Safety remains a paramount concern in the market, with continuous advancements in boiler safety systems and technologies. Condensing boilers, which recover heat from exhaust gases, have gained popularity due to their improved energy efficiency. Data centers, a significant consumer of industrial boilers, demand high-performance, reliable, and energy-efficient boiler systems to maintain their critical operations.

Process heating applications, another major market for industrial boilers, require boilers capable of delivering consistent temperatures and high steam flows. Boiler design and efficiency continue to be key focus areas, with ongoing research and development efforts aimed at optimizing fuel consumption and reducing emissions. Boiler corrosion, a persistent challenge, is being addressed through advanced materials and protective coatings. Emissions control, a critical aspect of industrial boiler operations, is becoming increasingly stringent due to regulatory requirements and environmental concerns. Boiler maintenance and inspections are essential to ensure optimal performance and longevity. The market encompasses a diverse range of applications, from power generation and chemical processing to food processing and textile mills.

Oil boilers, gas boilers, coal boilers, and biomass boilers cater to different fuel sources and industry-specific requirements. Renewable energy integration and boiler water treatment are emerging trends in the market, reflecting the industry's commitment to sustainability and efficiency. Boiler components, including tubes, controls, and insulation, undergo continuous innovation to enhance boiler performance and longevity. In the realm of power generation, industrial boilers play a crucial role in harnessing thermal energy from various fuel sources to generate electricity. Boiler capacity and fuel consumption are essential factors in power generation applications, where efficiency and reliability are paramount. The market is a dynamic and evolving landscape, shaped by a multitude of factors.

From boiler design and efficiency to safety and emissions control, the industry continues to innovate and adapt to meet the ever-changing needs of various industries.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Industrial Boiler Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

249 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.6% |

|

Market growth 2025-2029 |

USD 3.2 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

3.4 |

|

Key countries |

US, China, Japan, India, UK, Canada, Germany, South Korea, Italy, and France |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Industrial Boiler Market Research and Growth Report?

- CAGR of the Industrial Boiler industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the industrial boiler market growth and forecasting

We can help! Our analysts can customize this industrial boiler market research report to meet your requirements.