Liquid Nitrogen Market Size 2025-2029

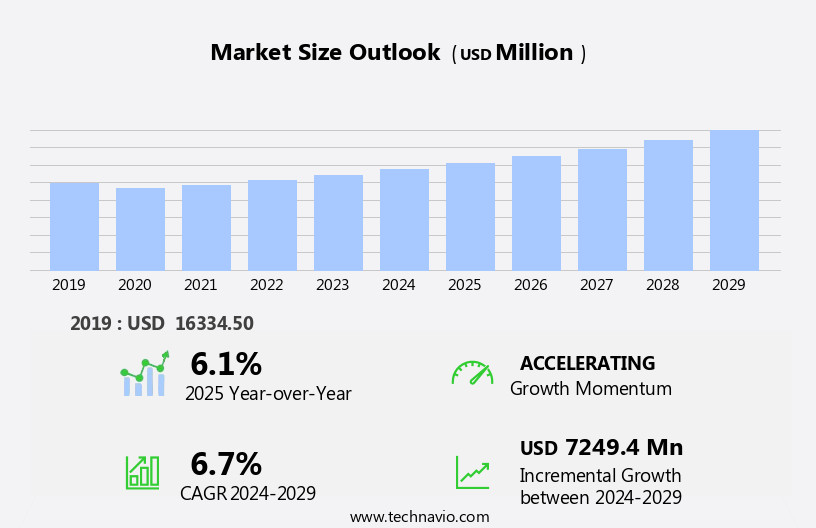

The liquid nitrogen market size is forecast to increase by USD 7.25 billion, at a CAGR of 6.7% between 2024 and 2029.

- The market is characterized by robust growth, driven by escalating demand from various sectors, particularly in the healthcare industry, where it is utilized as a jet medium in petroleum engineering for cryosurgery and preserving organs. This application segment is poised for significant expansion due to the increasing prevalence of chronic diseases and the rising number of organ transplantations. However, the market faces challenges stemming from the volatile prices of liquid nitrogen, which can impact profitability for manufacturers and end-users alike. This price instability is influenced by factors such as production costs, transportation, and supply and demand dynamics.

- Another challenge arises from the safety concerns associated with handling and storing liquid nitrogen due to its extremely low temperature and high pressures. Companies must invest in robust safety infrastructure and adhere to stringent regulatory requirements to mitigate risks and ensure customer confidence. In the food and beverage industry, liquid nitrogen is increasingly used for producing innovative and high-quality products, such as frozen desserts and specialty drinks, catering to consumers' evolving preferences. Additionally, the electronics sector leverages liquid nitrogen for cooling and quenching processes, enabling the production of advanced semiconductors and other high-tech components. To capitalize on the market's growth potential and navigate the challenges effectively, companies must focus on optimizing their supply chain and production processes, investing in safety infrastructure, and exploring opportunities in emerging applications.

- By staying informed of market trends and proactively addressing challenges, businesses can position themselves for long-term success in the dynamic the market.

What will be the Size of the Liquid Nitrogen Market during the forecast period?

The market continues to evolve, driven by the diverse applications of this versatile substance across various sectors. Cryogenic vaporization transforms nitrogen gas into its liquid state, which is utilized in numerous industries for cryogenic temperature control, material testing, and cryogenic propulsion, among others. Nitrogen gas condensation plays a crucial role in the production of liquid nitrogen, while nitrogen gas storage solutions ensure its safe and efficient handling. Cryogenic level sensing and cryogenic pressure regulation are essential components of nitrogen gas distribution systems, enabling seamless transportation and delivery. Nitrogen gas pipelines facilitate the large-scale transportation of this essential industrial gas, while nitrogen gas purification ensures the highest levels of nitrogen purity for specific applications.

Nitrogen gas monitoring and cryogenic leak detection are integral to maintaining safety practices and optimizing processes. In the medical field, liquid nitrogen is used for cryotherapy, while in the food industry, it is employed for preservation. Nitrogen gas is also a vital component in semiconductor manufacturing, vacuum insulation, and cryogenic energy efficiency. The aerospace industry relies on liquid nitrogen for cryogenic fuel and cryogenic refrigeration, while Cryogenic Insulation is essential for maintaining low temperatures in various applications. Nitrogen gas cost and production methods continue to be key market dynamics, with ongoing research and innovation driving advancements in nitrogen gas dewars, cryogenic energy efficiency, and cryogenic process optimization.

How is this Liquid Nitrogen Industry segmented?

The liquid nitrogen industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Application

- Chemical/pharma/biotech

- Food and beverages

- Metal manufacturing and construction

- Others

- Usage

- Coolant

- Refrigerant

- Technology

- Cryogenic distillation

- Pressure swing adsorption

- Others

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South America

- Brazil

- Rest of World (ROW)

- North America

By Application Insights

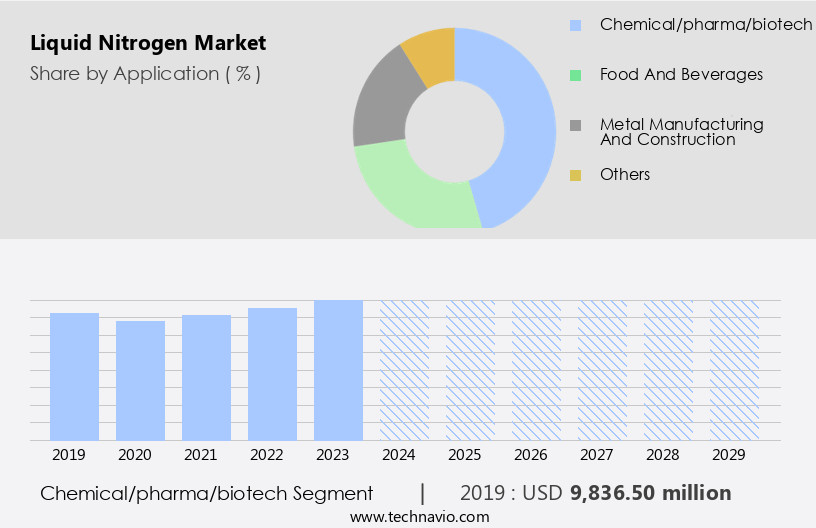

The chemical/pharma/biotech segment is estimated to witness significant growth during the forecast period.

In the realm of industrial applications, liquid nitrogen plays a pivotal role, particularly in the chemical industry. Its primary functions include pressurizing gases and transporting liquids via pipelines through cryogenic vaporization. Additionally, it inerts chemicals, cools reactors, shields them from oxygen exposure, and aids in the treatment of volatile organic compounds (VOCs). The environmental significance of liquid nitrogen is noteworthy, as it serves as an effective refrigerant that condenses VOCs at low temperatures, thereby reducing emissions and promoting product recovery and recycling. Indirect heat exchange is the method of application for liquid nitrogen as a refrigerant, while warmed nitrogen is utilized for purging and blanketing purposes.

The applications of liquid nitrogen extend to various industries, including food preservation using dewar flasks, semiconductor manufacturing, medical cryotherapy, and the aerospace industry. Cryogenic temperature control, pressure regulation, level sensing, and energy efficiency are essential aspects of handling and utilizing liquid nitrogen. Furthermore, nitrogen gas purification, distribution, transportation, and storage are integral processes in maintaining its quality and ensuring safety practices. Cryogenic insulation, leak detection, process optimization, and fuel for cryogenic refrigeration and propulsion systems are additional applications. Superconducting magnets also benefit from the application of liquid nitrogen for cooling and maintaining extremely low temperatures.

The Chemical/pharma/biotech segment was valued at USD 9.84 billion in 2019 and showed a gradual increase during the forecast period.

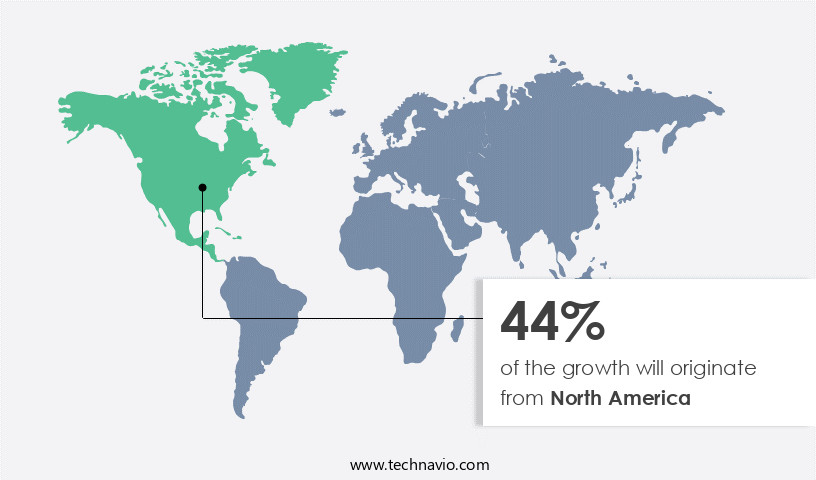

Regional Analysis

North America is estimated to contribute 44% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

In North America, the market showcases significant potential across various industries, including healthcare, food and beverage, chemicals, electronics, and metal manufacturing. Liquid nitrogen's unique properties make it an indispensable cryogenic fluid. In healthcare, it plays a crucial role in the transportation and storage of biological samples, cryopreservation of cells, and various medical procedures. The food and beverage industry utilizes liquid nitrogen for rapid freezing and preservation, ensuring product quality and longevity. In chemical processes, liquid nitrogen is employed for inerting, purging, and as a cooling agent. The electronics industry leverages liquid nitrogen for cooling in semiconductor manufacturing and other high-tech applications.

Additionally, liquid nitrogen is essential in metal manufacturing for cryogenic grinding, cryogenic temperature control, and cryogenic pressure regulation. In the aerospace industry, liquid nitrogen is used as cryogenic fuel and in cryogenic refrigeration and insulation systems. Nitrogen gas production, storage, distribution, and transportation are integral aspects of the market. Nitrogen gas purification, monitoring, and analysis are essential for maintaining optimal nitrogen gas density and purity levels. Cryogenic level sensing, leak detection, and process optimization ensure safety and efficiency. Vacuum insulation and cryogenic energy efficiency are also critical factors driving market growth. Cryogenic temperature control and cryogenic safety practices are essential for handling liquid nitrogen, ensuring its safe use in various industries.

Superconducting magnets and nitrogen gas dewars are additional applications of liquid nitrogen. Overall, the North American the market is a dynamic and evolving landscape, with extensive applications in various industries.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Liquid Nitrogen Industry?

- The healthcare industry's growing demand is the primary driver propelling market expansion.

- The market is significantly driven by the healthcare industry due to the increasing demand for cryopreservation applications. Cryopreservation is a process that involves freezing and storing biological samples, such as human cells and tissues, for future use in medical treatments. Liquid nitrogen is utilized as a cryoprotectant to preserve these samples, ensuring their viability over an extended period. The healthcare sector's growth is attributed to the rising prevalence of chronic diseases and the need for personalized medicine. For instance, in vitro fertilization (IVF) clinics use liquid nitrogen to preserve embryos, and stem cell banks store stem cells in liquid nitrogen for future use in regenerative medicine.

- Furthermore, the aerospace industry uses liquid nitrogen as a cryogenic fuel and in cryogenic refrigeration systems, while the industrial sector employs it in nitrogen gas production and cryogenic insulation for maintaining low temperatures. Cryogenic safety practices are crucial in these applications to ensure safe handling and storage of liquid nitrogen. Nitrogen gas cost is a significant factor influencing the market's growth, with increasing demand leading to price fluctuations. Additionally, advancements in nitrogen gas analysis technology and the integration of superconducting magnets in various industries are expected to further drive market growth.

What are the market trends shaping the Liquid Nitrogen Industry?

- In the realm of petroleum engineering, the utilization of liquid nitrogen as a jet medium is gaining significant traction as the next market trend. This innovative approach offers numerous advantages, including improved efficiency and enhanced safety in various oil and gas applications.

- Liquid nitrogen, a cryogenic substance, plays a significant role in various industries, particularly in petroleum engineering. In this field, liquid nitrogen undergoes cryogenic vaporization during the process of nitrogen gas condensation, which makes it an effective medium for cleaning oil wells, pipelines, and related equipment. This application is referred to as nitrogen lifting or nitrogen jetting. The process involves injecting the liquid nitrogen at high pressure, causing it to expand rapidly and generate a high-velocity jet stream. This jet stream can dislodge and remove impurities such as blockages, scale, and debris. Nitrogen gas storage and distribution are crucial for ensuring a consistent supply of liquid nitrogen for these applications.

- Cryogenic level sensing and temperature control systems are essential components in the nitrogen gas storage and distribution infrastructure to maintain the required cryogenic conditions. Furthermore, nitrogen gas pipelines facilitate the transportation of nitrogen gas from storage facilities to various industrial sites. In addition to petroleum engineering, liquid nitrogen is also employed in cryogenic propulsion systems and material testing applications due to its extreme cold temperature and unique properties. These applications demonstrate the versatility and importance of liquid nitrogen in various industries.

What challenges does the Liquid Nitrogen Industry face during its growth?

- The volatile pricing of liquid nitrogen poses a significant challenge to the growth of the industry.

- Liquid nitrogen is a critical industrial gas with diverse applications, including cryogenic transport vessels, nitrogen gas purification, medical cryotherapy, nitrogen gas monitoring, cryogenic grinding, and food preservation. The market for this versatile gas is subject to various dynamic factors that influence its pricing and demand. The price of liquid nitrogen is influenced by supply and demand, energy prices, and the cost of raw materials. Fluctuations in these factors can lead to unpredictable pricing, posing challenges for both producers and consumers. Producers face uncertainty regarding revenue and profits due to volatile pricing, while consumers may experience increased costs or supply disruptions.

- In the production of liquid nitrogen, nitrogen gas is cooled to a temperature of -196 degrees Celsius, resulting in a liquid state. Its unique properties, such as low nitrogen gas viscosity and high cryogenic pressure regulation, make it an essential component in various industries. Dewar flasks are commonly used for storing and transporting liquid nitrogen due to their insulating properties. Cryogenic applications, such as medical cryotherapy and food preservation, rely on the unique properties of liquid nitrogen. Medical cryotherapy is used for treating various conditions, including sports injuries and arthritis, while food preservation extends the shelf life of perishable goods.

- Cryogenic grinding is another application that utilizes liquid nitrogen's low temperature to grind materials into fine particles. In conclusion, the market is influenced by various dynamic factors that can lead to volatile pricing. Its unique properties make it an essential component in various industries, from medical applications to food preservation. Producers and consumers alike must navigate the challenges of unpredictable pricing and supply to effectively utilize this versatile gas.

Exclusive Customer Landscape

The liquid nitrogen market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the liquid nitrogen market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, liquid nitrogen market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Air Liquide SA - The company specializes in providing liquid nitrogen solutions for various industries, including food and beverage, healthcare, electronics, and manufacturing.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Air Liquide SA

- Air Products and Chemicals Inc.

- AMCS Corp.

- Asia Industrial Gases Pte. Ltd.

- Asia Technical Gas Co. Pte. Ltd.

- Buzwair Industrial Gases Factories

- Cryomech Inc.

- Goyal Group

- Gulfcryo

- Linde Plc

- Messer SE and Co. KGaA

- MVS Engineering Pvt. Ltd.

- Nippon Sanso Holdings Co. Ltd.

- Statebourne Cryogenics Ltd.

- Yingde Gas Group Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Liquid Nitrogen Market

- In February 2024, Air Liquide, a global leader in gases, announced the expansion of its liquid nitrogen production capacity in the United States. The USD150 million investment aims to increase production by 25%, catering to the growing demand in the energy and industrial sectors (Air Liquide press release, 2024).

- In June 2023, Linde plc and Praxair, Inc. Completed their merger, creating Linde plc, a leading gases and engineering company. The combined entity, with a strong presence in the market, will leverage synergies to enhance its product offerings and global reach (Linde plc press release, 2023).

- In October 2025, Air Products and Chemicals, Inc. Introduced CryoEase, a new liquid nitrogen transportation solution designed to improve safety and efficiency. The innovative system uses advanced insulation and pressure relief technologies, reducing the need for frequent refills and minimizing the risk of cryogenic spills (Air Products and Chemicals press release, 2025).

- In March 2024, the European Union approved new regulations on the use of liquid nitrogen in food processing. The guidelines aim to ensure food safety while reducing the environmental impact of industrial processes. The new rules are expected to drive demand for sustainable and efficient liquid nitrogen solutions in the European market (European Commission press release, 2024).

Research Analyst Overview

- In the dynamic cryogenic market, advancements in cryogenic science continue to drive innovation in various sectors. Cryogenic control systems and maintenance of cryogenic equipment are crucial for ensuring optimal performance and safety. Cryogenic materials science and engineering play a pivotal role in the development of cryogenic instrumentation and sensors, which facilitate cryogenic data analysis and risk assessment. Cryogenic process control and automation rely on cryogenic actuators and thermodynamics, while cryogenic heat transfer and fluid mechanics are essential for efficient energy management. Cryogenic process optimization and safety regulations are key concerns for industry standards, with cryogenic technology and vacuum technology playing a significant role in addressing these challenges.

- Moreover, cryogenic data acquisition and process simulation enable businesses to improve sustainability and enhance overall operational efficiency. Cryogenic environmental monitoring and sustainability are becoming increasingly important, with regulations and industry standards evolving to address these concerns. In summary, the cryogenic market is characterized by continuous innovation in cryogenic science, engineering, and technology, with a focus on safety, efficiency, and sustainability. Cryogenic control systems, maintenance, instrumentation, data analysis, risk assessment, process control, actuators, sensors, thermodynamics, fluid mechanics, simulation, sustainability, industry standards, and vacuum technology are all integral components of this dynamic and evolving industry.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Liquid Nitrogen Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

222 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6.7% |

|

Market growth 2025-2029 |

USD 7249.4 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

6.1 |

|

Key countries |

US, China, Canada, Japan, India, Brazil, UK, Germany, France, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Liquid Nitrogen Market Research and Growth Report?

- CAGR of the Liquid Nitrogen industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, APAC, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the liquid nitrogen market growth of industry companies

We can help! Our analysts can customize this liquid nitrogen market research report to meet your requirements.