Neodymium (NdFeB) Magnets Market Size 2025-2029

The neodymium (ndfeb) magnets market size is forecast to increase by USD 7.65 billion, at a CAGR of 8.5% between 2024 and 2029.

- The market is experiencing significant growth, driven by the increasing focus on renewable energy sources and the surging demand for Electric Vehicles (EVs). These magnets are essential components in wind turbines and EV motors, making them indispensable in the transition towards cleaner energy solutions. However, the high cost of production poses a considerable challenge for market participants. The manufacturing process of NdFeB magnets involves the use of rare earth elements, which are scarce and expensive. This scarcity, coupled with the complex production process, contributes to the high production costs. To capitalize on the market opportunities, companies must explore cost-effective production methods and seek alternative sources for rare earth elements.

- Additionally, collaborations and partnerships with raw material suppliers and technology providers can help mitigate the production cost challenge and ensure a steady supply of raw materials. In summary, the market is poised for growth due to the increasing demand from renewable energy and EV sectors, but the high production costs present a significant challenge that requires innovative solutions and strategic partnerships.

What will be the Size of the Neodymium (NdFeB) Magnets Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2019-2023 and forecasts 2025-2029 - in the full report.

Request Free Sample

Neodymium magnets, also known as NdFeB magnets or rare-earth magnets, continue to dominate the magnetic market due to their exceptional magnetic properties and versatile applications. These magnets, primarily composed of neodymium, iron, and boron, exhibit high magnetic moment, strong magnetic field strength, and high energy product. The market dynamics of neodymium magnets are continually evolving, driven by advancements in technology and increasing demand across various sectors. In generator applications, neodymium magnets enhance the efficiency of wind turbines and electric motors. Magnetic bearings and magnetic levitation (maglev) systems utilize these magnets for their ability to support loads without physical contact, ensuring smooth operation and reducing wear and tear.

Hall effect sensors and magnetic moment sensors benefit from the magnetic properties of neodymium magnets, enabling precise measurement and control in various industries. Quality control measures, such as hysteresis loop analysis and magnetic flux leakage detection, ensure the consistency and reliability of these magnets. Neodymium magnets find extensive use in consumer electronics, automotive applications, and medical devices. Their temperature stability makes them suitable for data storage systems and waste management applications. In addition, they are used in magnetic separation processes, magnetic shielding, and precision machining. The magnetic properties of neodymium magnets, including their high magnetic field strength and magnetic flux density, make them essential in motor applications and magnetic field sensors.

Furthermore, their environmental impact and manufacturing processes, such as powder metallurgy and injection molding, continue to be areas of research and development. The supply chain for neodymium magnets is complex, with raw materials sourced from various regions and subject to price volatility. Bonded NdFeB magnets and sintered NdFeB magnets cater to different market needs, with the former offering better dimensional stability and the latter providing higher energy product. As the market for neodymium magnets continues to grow and evolve, the demand for advanced magnetic materials, manufacturing techniques, and quality control measures will persist. The ongoing research and development in this field will undoubtedly lead to new applications and innovations, further solidifying the importance of neodymium magnets in various industries.

How is this Neodymium (NdFeB) Magnets Industry segmented?

The neodymium (ndfeb) magnets industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Type

- Sintered

- Bonded

- End-user

- Automotive

- Electronics

- Power generators

- Medical industry

- Others

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- UK

- APAC

- Australia

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Type Insights

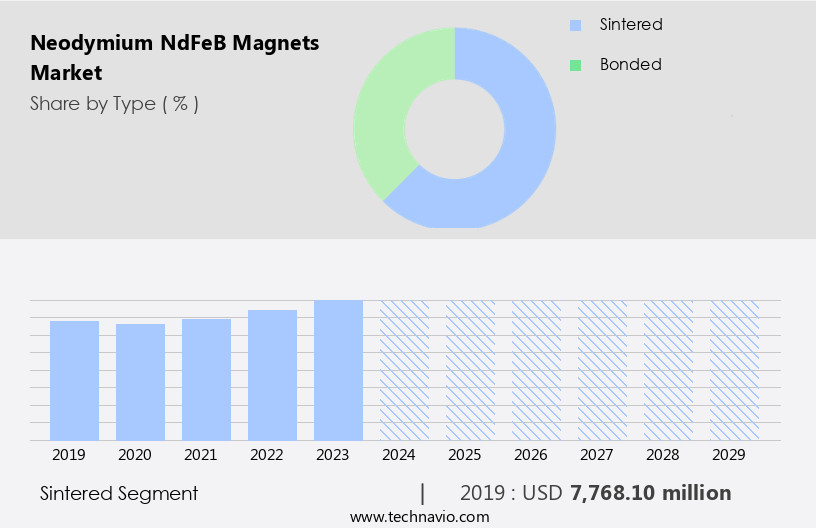

The sintered segment is estimated to witness significant growth during the forecast period.

Neodymium magnets, specifically sintered NdFeB magnets, are renowned for their magnetic properties and efficiency in various industries. Manufactured through the process of compressing and heating a mixture of NdFeB, iron, and boron powders, these magnets offer a high energy density, magnetic loss, and coercivity. This makes them indispensable in numerous applications, including automotive, consumer electronics, medical devices, and renewable energy. In the automotive sector, sintered NdFeB magnets power the motors of Electric Vehicles (EVs), contributing to their propulsion. Meanwhile, in consumer electronics, they are utilized in various devices due to their strong magnetic field and small size. In medical devices, they ensure precision and accuracy through magnetic separation and magnetic field sensors.

Within the renewable energy sector, wind turbines rely on these magnets for their generator applications, enhancing their efficiency and performance. Moreover, sintered NdFeB magnets exhibit excellent corrosion resistance, ensuring longevity in harsh environments. They are also used in magnetic bearings, magnetic levitation systems, and magnetic field sensors. In addition, they are employed in magnetic shielding, surface treatment, injection molded NdFeB, and permanent magnets. Their high magnetic flux density and magnetic field strength make them suitable for motor applications, while their environmental impact is being addressed through advancements in magnet manufacturing and recycling. Furthermore, sintered NdFeB magnets are used in actuator applications, temperature stability, and waste management, showcasing their versatility.

Their magnetic moment and hysteresis loop properties are utilized in various applications, including magnetic flux leakage and fluxgate sensors. The raw materials used in their production, such as bonded NdFeB and energy product, undergo rigorous quality control processes to ensure consistency and reliability. In conclusion, sintered NdFeB magnets play a significant role in various industries due to their exceptional magnetic properties and cost-effectiveness. Their versatility is demonstrated through their use in automotive, consumer electronics, medical devices, renewable energy, and other applications, making them an essential component in numerous technological advancements.

The Sintered segment was valued at USD 7.77 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 53% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in the Asia Pacific (APAC) region is experiencing significant growth due to the increasing demand for high-performance magnets in various industries. Rare-earth magnets, including samarium cobalt and neodymium magnets, are crucial in applications such as wind turbines, consumer electronics, automotive, and generator systems. The APAC region's industrialization and infrastructure development contribute to the market's expansion. Neodymium magnets, specifically, are gaining popularity due to their magnetic properties, including high magnetic field strength, magnetic moment, and energy product. They are used in various applications, such as magnetic bearings, magnetic levitation (maglev) systems, magnetic field sensors, and actuators. In the automotive sector, they are employed in electric vehicles (EVs) to produce efficient and powerful motors, contributing to the demand for lightweight and fuel-efficient vehicles.

Moreover, the medical devices sector relies on neodymium magnets for their temperature stability and magnetic properties. In the energy sector, they are used in magnetic separation processes and in the production of permanent magnets. The ceramic magnets market, a subset of the rare-earth magnets market, is also experiencing growth due to its applications in magnetic field sensors and magnetic shielding. The supply chain for rare-earth magnets is complex, with raw materials sourced primarily from China. However, efforts are being made to reduce reliance on a single supplier through alternative sourcing and recycling initiatives. Quality control is a critical factor in the manufacturing process, with hysteresis loop, demagnetization curve, and magnetic flux leakage being essential considerations.

Furthermore, the environmental impact of rare-earth magnet manufacturing is a concern, with efforts being made to minimize waste and improve the sustainability of the production process. Magnet manufacturing techniques, such as powder metallurgy, injection molding, and sintering, are being refined to improve efficiency and reduce waste. In conclusion, the market in the APAC region is experiencing growth due to the increasing demand for high-performance magnets in various industries. The magnetic properties of neodymium magnets, including high magnetic field strength, magnetic moment, and energy product, make them ideal for applications in automotive, electronics, energy, and healthcare sectors. The complex supply chain and environmental concerns are challenges that the industry must address to ensure sustainable growth.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market is a significant sector in the global magnetic materials industry, driven by its high magnetic strength and versatile applications. Neodymium magnets, also known as rare earth magnets, are primarily used in various industries such as automotive, electronics, renewable energy, and manufacturing. Their magnetic properties make them essential in motors, generators, actuators, and magnetic separators. The market's growth is fueled by increasing demand for energy-efficient technologies and the expanding electric vehicle market. Key players in the value chain include raw material suppliers, magnet manufacturers, and end-users. The market's competitiveness is driven by factors like technological advancements, price volatility, and supply chain disruptions. Regulatory initiatives and trade policies also impact the market's dynamics. Despite challenges, the neodymium magnets market continues to offer opportunities for innovation and growth.

What are the key market drivers leading to the rise in the adoption of Neodymium (NdFeB) Magnets Industry?

- The shift towards renewable energy sources is the primary market trend, with an increasing emphasis placed on sustainable and eco-friendly power solutions.

- The market is witnessing a notable transition towards renewable energy applications. With growing concerns over the environmental impact of traditional energy sources, there is a heightened emphasis on sustainable alternatives, such as solar, bioenergy, tidal energy, and wind energy. NdFeB magnets are essential components in the production of renewable energy solutions, particularly in wind turbines and electric vehicles (EVs), making them indispensable in the global energy transition. Rare-earth magnets, including NdFeB magnets, are crucial due to their high energy product and strong magnetic field. Samarium cobalt magnets are alternative options, but NdFeB magnets offer superior magnetic performance and are more cost-effective.

- The corrosion resistance of NdFeB magnets is another significant advantage, making them suitable for harsh environments. NdFeB magnets' demagnetization curve is another factor contributing to their popularity. The ability to maintain magnetic properties at high temperatures and under strong magnetic fields makes them ideal for various applications, including magnetoresistance sensors, magnetic separation, and consumer electronics. The supply chain for NdFeB magnets is complex due to the rare-earth elements' scarcity. However, advancements in recycling technologies and alternative sources are expected to alleviate supply concerns. Automotive applications are another significant market for NdFeB magnets, with their use in electric motors, hybrid vehicles, and fuel efficiency systems.

- In summary, the market is experiencing significant growth due to the increasing demand for renewable energy solutions and the unique properties of NdFeB magnets. Their role in wind turbines, EVs, and various other applications makes them a critical component of the global energy transition.

What are the market trends shaping the Neodymium (NdFeB) Magnets Industry?

- The professional and knowledgeable response to your inquiry is as follows: The growing demand for electric vehicles (EVs) represents a significant market trend in the transportation industry. This trend is driven by increasing environmental consciousness, advancements in technology, and government incentives to reduce carbon emissions.

- The market is witnessing significant growth due to the increasing adoption of these magnets in various industries, particularly in generator applications for renewable energy systems and electric vehicles (EVs). NdFeB magnets are preferred for their exceptional magnetic properties, including high magnetic moment, strong magnetic field, and narrow hysteresis loop. These magnets are essential in the manufacturing of powerful and efficient electric motors, which are widely used in wind turbines and EVs. In the EV sector, NdFeB magnets are integral to the operation of electric motors, magnetic bearings, and magnetic levitation (maglev) systems. Maglev technology is used in high-speed trains and other transportation applications, offering smooth and efficient motion.

- Moreover, NdFeB magnets are utilized in hall effect sensors, ensuring precise measurement of magnetic fields in various applications, including EVs and industrial automation. Quality control is crucial in the production of NdFeB magnets, as magnetic flux leakage and other defects can significantly impact their performance. In the medical devices and data storage industries, NdFeB magnets are employed for their magnetic properties to enhance functionality and efficiency. Overall, the global demand for NdFeB magnets is expected to continue growing as industries seek more efficient and eco-friendly solutions.

What challenges does the Neodymium (NdFeB) Magnets Industry face during its growth?

- The high production cost of NdFeB magnets poses a significant challenge and impedes the growth of the related industry.

- Neodymium magnets, specifically NdFeB magnets, are known for their high magnetic field strength, making them essential in various industries, including motor applications and magnetic field sensors. However, the production of NdFeB magnets is costly due to the use of expensive raw materials, such as neodymium, boron, and iron, and the labor-intensive extraction and refining process. This high production cost translates to a premium price for NdFeB magnets, which can be a challenge for manufacturers of electronic devices that utilize them, such as high-performance speakers, computer hard drives, and electric vehicles. Despite the cost, NdFeB magnets are preferred for their temperature stability and strong magnetic flux density, outperforming alternatives like ferrite and alnico magnets in many applications.

- Waste management is another area where NdFeB magnets play a crucial role, particularly in magnetic separation systems for recycling applications. The high cost notwithstanding, the demand for NdFeB magnets continues to grow due to their unique properties and wide range of applications.

Exclusive Customer Landscape

The neodymium (ndfeb) magnets market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the neodymium (ndfeb) magnets market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, neodymium (ndfeb) magnets market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Adams Magnetic Products - Specializing in Neodymium magnets, we provide solutions through diverse offerings. Neodymium Magnet Discs, Rings, and Blocks enhance performance in various applications. Our expertise lies in delivering high-quality magnets, ensuring optimal functionality. Neodymium magnets' unique properties offer superior strength and versatility, making them an essential component in numerous industries.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Adams Magnetic Products

- Advanced Technology and Materials Co. Ltd.

- Arnold Magnetic Technologies Corp.

- Daido Steel Co. Ltd.

- DEXTER MAGNETIC TECHNOLOGIES

- Earth Panda Advance Magnetic Material Co.Ltd.

- Goudsmit Magnetics Groep BV

- Guangdong Lingyi Zhizhi Manufacturing Co. Ltd.

- MP MATERIALS CORP.

- Neo Performance Materials Inc.

- Ningbo ketian Magnet Co. Ltd.

- Ningbo Yunsheng Co. Ltd.

- Ningbo Zhaobao Magnet Co. Ltd.

- Proterial Ltd.

- Shin Etsu Chemical Co. Ltd.

- Spear and Jackson

- TDK Corp.

- Vacuumschmelze GmbH and Co. KG

- Zhejiang Innuovo Magnetics Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Neodymium (NdFeB) Magnets Market

- In January 2024, leading Neodymium (NdFeB) magnet manufacturer, Magnets Inc., announced the launch of its new high-performance NdFeB magnet series, named "Magnesforce X," designed for use in electric vehicles and renewable energy applications. This development aimed to strengthen Magnets Inc.'s position in the growing green technology sector (Magnets Inc. Press release).

- In March 2024, Neo-Mag Holdings, a significant Neodymium magnet supplier, entered into a strategic partnership with Tesla Motors to supply high-quality NdFeB magnets for Tesla's expanding electric vehicle lineup. This collaboration was expected to boost Neo-Mag Holdings' revenue and market share in the electric vehicle industry (Tesla Motors press release).

- In May 2024, Neo-Material Technologies, a pioneering Neodymium magnet technology developer, secured a USD25 million Series C funding round led by Khosla Ventures. The investment would be used to accelerate the commercialization of Neo-Material Technologies' innovative, cost-effective, and recyclable NdFeB magnet technology (Neo-Material Technologies press release).

- In January 2025, the European Union passed the new REACH regulation, which significantly increased the reporting requirements for Neodymium magnets containing more than 0.1% of neodymium, europium, gadolinium, terbium, or dysprosium. This regulation aimed to improve the transparency and safety of Neodymium magnet production and use within the EU (European Union press release).

Research Analyst Overview

- Neodymium magnets, specifically NdFeB magnets, are a key component in various industries, including automotive, wind energy, and electronics, due to their strong magnetic properties. The market for these magnets is driven by advancements in material science, particularly in the area of magnetic domains and stress anisotropy. Magnetic saturation and magnetic field lines are crucial factors in the electromagnetic simulation of these materials. Magnetic susceptibility, magnetic force, and magnetic poles are essential parameters in understanding the behavior of magnetic materials. Shape anisotropy and surface engineering play a significant role in optimizing the magnetic properties of NdFeB magnets. Exchange interaction and domain wall motion are important phenomena that influence magnetic hysteresis and the magnetic energy stored in the material.

- Powder characterization and particle size distribution are critical in ensuring consistent quality and performance. Magnetocrystalline anisotropy, magnetoelastic effect, and preisach model are advanced concepts used in the analysis of NdFeB magnets. Magnetic dipole moments and magnetic flux are fundamental concepts in the study of magnetic fields. Recoil permeability and intrinsic coercivity are essential properties that determine the magnetic performance of NdFeB magnets. The demagnetizing factor and squareness ratio are critical factors in optimizing the design and application of NdFeB magnets. Magnetic anisotropy energy and anisotropy fields, such as north pole and south pole, are essential parameters in the characterization and optimization of these magnets.

- Overall, the NdFeB magnet market is dynamic and evolving, driven by advancements in material science and engineering.

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Neodymium (NdFeB) Magnets Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

206 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 8.5% |

|

Market growth 2025-2029 |

USD 7650.5 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

7.7 |

|

Key countries |

China, US, Japan, India, Germany, Canada, South Korea, UK, France, and Australia |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Neodymium (NdFeB) Magnets Market Research and Growth Report?

- CAGR of the Neodymium (NdFeB) Magnets industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the neodymium (ndfeb) magnets market growth of industry companies

We can help! Our analysts can customize this neodymium (ndfeb) magnets market research report to meet your requirements.