Polyisoprene Rubber Market Size 2024-2028

The polyisoprene rubber market size is forecast to increase by USD 227 million at a CAGR of 8.5% between 2023 and 2028. The market is experiencing significant growth due to various driving factors. One key trend is the increasing demand for polyisoprene rubber in the healthcare sector, particularly for use in catheters, fluid transport tubing, and surgical tubing. In addition, the construction industry is also a significant consumer of polyisoprene rubber, utilizing it for industrial gloves and other applications. Another growing market is the production of condoms, which require high-quality, consistent materials. Furthermore, the shift towards the use of biomass-derived polyisoprene rubber is gaining momentum due to its environmental benefits, such as reduced CO2 emissions compared to traditional synthetic rubber production methods.

What will be the Size of the Market During the Forecast Period?

Polyisoprene rubber, a synthetic elastomer derived from isoprene monomer, has gained significant traction in various industries due to its unique properties. This elastomeric material offers excellent weather resistance, making it an ideal choice for applications in sectors such as automotive and medical. Isoprene monomer, the primary raw material for producing polyisoprene rubber, is derived from petroleum or natural sources like the Hevea brasiliensis tree. The polymer structure of polyisoprene rubber is identical to that of natural rubber, providing it with similar elasticity and flexibility. However, its synthetic nature offers additional benefits, including improved weather resistance and resistance to pathogens.

Moreover, the automotive sector is a significant consumer of polyisoprene rubber. Its use in the production of tires, belts, and sealants ensures improved performance and durability in extreme weather conditions. In the medical sector, this material is extensively used in the manufacturing of medical devices, such as medical gloves and balloons, due to its biocompatibility and resistance to tears and punctures. Adhesives and sealants are another major application area for polyisoprene rubber. Its ability to form strong bonds and withstand various temperatures and weather conditions makes it an excellent choice for these applications. Moreover, its resistance to pathogens makes it suitable for use in medical applications, such as wound care and medical equipment.

Furthermore, polyisoprene rubber's weather resistance also makes it an attractive alternative to natural rubber in various industries. Its use in the production of contraceptives, such as wearable contraceptives and condom designs, offers enhanced protection against unplanned pregnancies and sexually transmitted infections. The market is expected to grow due to its versatility and unique properties. Its applications span across various industries, including automotive, medical, and industrial, making it a valuable raw material for manufacturers. As the demand for high-performance materials continues to grow, the market for polyisoprene rubber is poised to expand. In conclusion, polyisoprene rubber is a valuable synthetic elastomer with unique properties that make it an ideal choice for various applications.

Market Segmentation

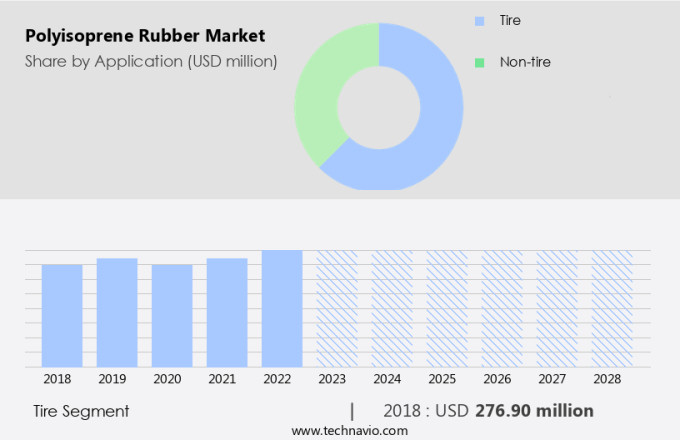

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Tire

- Non-tire

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- North America

- US

- South America

- Middle East and Africa

- APAC

By Application Insights

The tire segment is estimated to witness significant growth during the forecast period. The market is experiencing significant growth, particularly in the tire manufacturing sector. The increasing global demand for automobiles, with sales reaching approximately 66.7 million units in 2021 compared to 63.8 million units in 2020, is a primary driving factor. In tire production, black-loaded compounds are extensively used due to their advantages in producing specific critical compounds, ensuring quality, uniformity, and improved flow properties.

Furthermore, these properties enable tire manufacturers to meet stringent tire standards, such as steel-reinforced radial tires. In developed economies, the tire industry relies heavily on polyisoprene rubber to meet the high-performance demands of premium tires. This synthetic elastomer, with the chemical formula C5H8, is a crucial component in the tire industry.

Get a glance at the market share of various segments Request Free Sample

The tire segment accounted for USD 276.90 million in 2018 and showed a gradual increase during the forecast period.

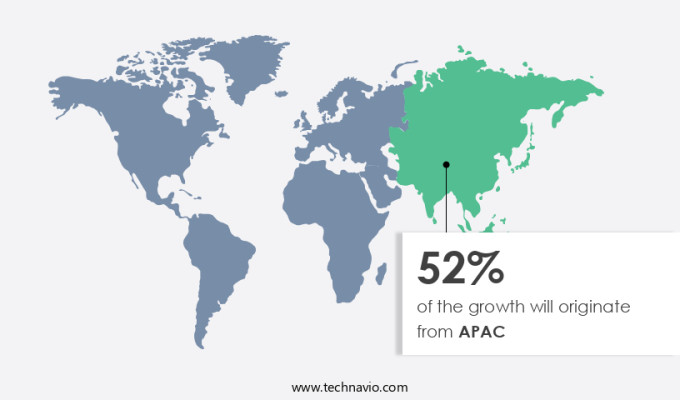

Regional Insights

APAC is estimated to contribute 52% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period. The increased use of polyisoprene rubber in end-user industries, especially in tire production applications will facilitate the polyisoprene rubber market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Market Driver

Increasing demand from the tire industry is the key driver of the market. Polyisoprene rubber holds significant importance in various industries, with the tire sector being a major consumer. The automotive industry is the largest market for polyisoprene rubber due to its extensive usage in tire production, including automobile, bicycle, and aviation tires. The increasing prices of natural rubber have led tire manufacturers to seek alternatives, and polyisoprene rubber, being an affordable synthetic option, has gained popularity.

Furthermore, synthetic rubber's adoption is not only due to cost savings but also because of its enhanced product quality. It increases the tensile strength of tires, contributing to their durability and improved rolling resistance. These features make polyisoprene rubber an ideal choice for passenger car and motorcycle tires, providing superior grip performances. Beyond tires, polyisoprene rubber also finds applications in other industries such as belts, footwear, medical accessories, medical gloves, and medical balloons. In summary, the versatility and affordability of polyisoprene rubber make it an indispensable component in various industries, with the tire sector leading the market.

Market Trends

Rising demand for biomass-derived polyisoprene rubber is the upcoming trend in the market. The production of synthetic rubber utilizing bio-based feedstock is an emerging trend in the industry. The drive towards sustainability is fueling the rapid advancement of renewable chemicals used in rubber manufacturing. The escalating costs and unpredictable availability of monomers and natural rubber have encouraged the adoption of renewable feedstock in the synthesis of synthetic rubber. Key market participants are actively investing in producing polyisoprene rubber from bio-sources. They are forging alliances with industrial biotech companies to progress the commercial production of bio-based raw materials.

Furthermore, this shift towards sustainable rubber production is gaining traction in various sectors, including medical, industrial, and consumer goods, such as catheters, fluid transport tubing, surgical tubing, industrial gloves, construction sectors, condoms, and more.

Market Challenge

Recovery of the natural rubber market is a key challenge affecting the market growth. The Synthetic Isoprene market, specifically in the sectors of Adhesives and Sealants, has experienced significant growth due to the advantages offered by polyisoprene rubber. This raw material, which can be both synthetic and derived from natural rubber, boasts superior weather-resistant properties, making it an ideal choice for various applications. In the medical device industry, for instance, its use is prevalent due to its biocompatibility and flexibility. In the Automotive sector, the adoption of polyisoprene rubber in vehicle manufacturing has increased due to its durability and resistance to extreme temperatures.

Further, the recent increase in natural rubber prices has been a significant factor contributing to the growth of the synthetic isoprene market. This trend can be attributed to various factors, including the Organization of the Petroleum Exporting Countries' (OPEC) decision to cut crude oil supply, which led to a rise in crude oil prices. Consequently, the prices of natural rubber, a primary raw material for synthetic isoprene production, also increased. This development has made synthetic isoprene a more cost-effective alternative, leading to its increased adoption in various industries. In conclusion, the synthetic isoprene market is poised for continued growth in the US market due to its versatility, durability, and weather-resistant properties.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

JSR Corp.: The company offers polyisoprene rubbers for tires, belts, various industrial products, shoes, adhesives, rubber threads, rubber bands, surgical gloves, and balloon catheter.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Bridgestone Corp.

- Chemspec Ltd.

- China Petrochemical Corp.

- DuPont de Nemours Inc.

- Eni SpA

- JSR Corp.

- Kent Elastomer Products Inc.

- Kraton Corp.

- KURARAY Co. Ltd.

- Lanxess AG

- Lotte Corp.

- Ningbo Jinhai ChenguangChemical Corp.

- Puyang United Chemical Co. Ltd.

- Qingdao Tpi New Material Co. Ltd.

- SIBUR Holding PJSC

- Sintez Kauchuk JSC

- The Goodyear Tire and Rubber Co.

- TotalEnergies SE

- Yokohama Rubber Co. Ltd.

- Zeon Corp.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The synthetic isoprene market is witnessing significant growth due to the increasing demand for polyisoprene rubber in various industries. This synthetic elastomer is widely used in the production of tires, belts, footwear, medical accessories, and adhesives and sealants. In the automotive sector, polyisoprene is preferred for its weather-resistant properties, making it an ideal choice for tire manufacturing. The medical devices industry is another major consumer of polyisoprene rubber. It is extensively used in the production of medical gloves, catheters, fluid transport tubing, and surgical tubing. The material's excellent resistance to pathogens makes it a popular choice in medical supplies.

Further, the construction sector also utilizes polyisoprene rubber in the production of industrial gloves, providing workers with enhanced protection against harsh environments. The material's versatility extends to the production of condoms, where it offers superior wearability, resealability, and needle penetration resistance. The tire manufacturing industry's shift towards producing tires for electric and driverless cars is expected to further boost the demand for polyisoprene rubber. However, the increasing focus on reducing CO2 emissions and the availability of substitute materials like polystyrene, butadiene, and neoprene may pose a challenge to the market's growth. Polyisoprene rubber, also known as C5H8, is a synthetic elastomer derived from the isoprene monomer.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

148 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 8.5% |

|

Market growth 2024-2028 |

USD 227 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

7.66 |

|

Regional analysis |

APAC, Europe, North America, South America, and Middle East and Africa |

|

Performing market contribution |

APAC at 52% |

|

Key countries |

China, US, Japan, Germany, and Russia |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

Bridgestone Corp., Chemspec Ltd., China Petrochemical Corp., DuPont de Nemours Inc., Eni SpA, JSR Corp., Kent Elastomer Products Inc., Kraton Corp., KURARAY Co. Ltd., Lanxess AG, Lotte Corp., Ningbo Jinhai ChenguangChemical Corp., Puyang United Chemical Co. Ltd., Qingdao Tpi New Material Co. Ltd., SIBUR Holding PJSC, Sintez Kauchuk JSC, The Goodyear Tire and Rubber Co., TotalEnergies SE, Yokohama Rubber Co. Ltd., and Zeon Corp. |

|

Market dynamics |

Parent market analysis, market growth inducers and obstacles, market forecast, fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, market condition analysis for the forecast period |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch