Printed Circuit Board (PCB) Market Size 2025-2029

The printed circuit board (pcb) market size is valued to increase USD 26.8 billion, at a CAGR of 6.2% from 2024 to 2029. Rising adoption of smartphones will drive the printed circuit board (pcb) market.

Major Market Trends & Insights

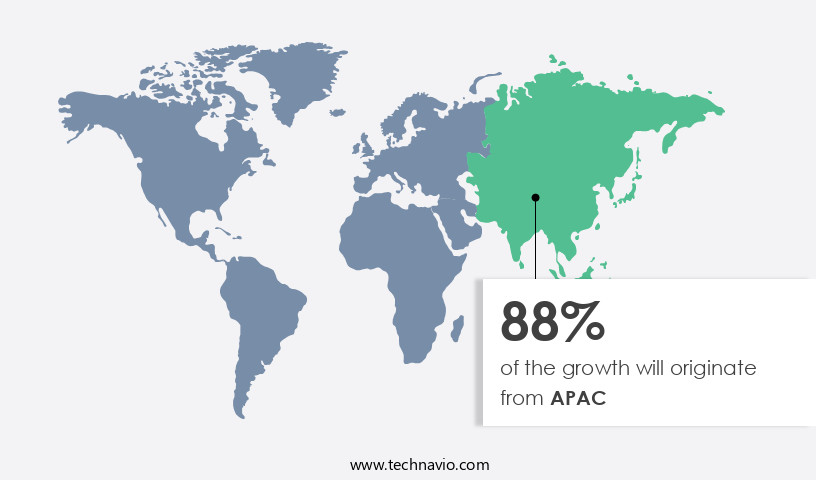

- APAC dominated the market and accounted for a 88% growth during the forecast period.

- By Type - Multi-layer segment was valued at USD 22.00 billion in 2023

- By End-user - Communication network infrastructure segment accounted for the largest market revenue share in 2023

Market Size & Forecast

- Market Opportunities: USD 57.75 billion

- Market Future Opportunities: USD 26.80 billion

- CAGR from 2024 to 2029 : 6.2%

Market Summary

- The market experiences continuous expansion, fueled by the escalating demand for electronic devices. According to a recent study, the global PCB industry is projected to surpass USD100 billion by 2027, underscoring its significant economic impact. This growth is driven by several factors, including the increasing adoption of advanced technologies such as the Internet of Things (IoT), 5G networks, and wearable devices. Moreover, the industry's shift towards flexibility and automation is a notable trend. Flexible PCBs, which can be bent or folded, are gaining popularity due to their ability to accommodate complex designs and reduce the size of electronic devices.

- Automation in PCB manufacturing processes enhances efficiency, reduces production costs, and ensures consistency in product quality. However, environmental concerns pose a challenge to the PCB market. The industry's reliance on heavy metals and toxic chemicals for manufacturing processes raises concerns about their impact on the environment and human health. As a result, there is a growing emphasis on developing eco-friendly manufacturing methods and recycling initiatives. In conclusion, the Printed Circuit Board market's future direction is shaped by technological advancements, industry trends, and environmental concerns. The market's continued growth is expected to bring about new opportunities and challenges for businesses in the electronics industry.

What will be the Size of the Printed Circuit Board (PCB) Market during the forecast period?

Get Key Insights on Market Forecast (PDF) Request Free Sample

How is the Printed Circuit Board (PCB) Market Segmented ?

The printed circuit board (pcb) industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Type

- Multi-layer

- HDI

- Single sided

- Double sided

- End-user

- Communication network infrastructure

- IT and peripherals

- Automotive

- Consumer electronics

- Others

- Substrate

- FR-4 (Flame Retardant 4)

- Polymide

- Metal Core

- Others (Ceramic, PTFE, etc.)

- Organization Size

- Small and Medium Enterprises (SMEs)

- Large Enterprises

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- Middle East and Africa

- Egypt

- KSA

- Oman

- UAE

- APAC

- China

- India

- Japan

- Taiwan

- South America

- Argentina

- Brazil

- Rest of World (ROW)

- North America

By Type Insights

The multi-layer segment is estimated to witness significant growth during the forecast period.

The market continues to evolve, with multi-layer PCBs holding a significant market share in 2024. These intricate boards, composed of multiple layers of substrate material connected by conductive channels, cater to the increasing demand for compact, high-performance electronic devices. Industries like telecommunications, automotive, and consumer electronics are major contributors to this trend. For instance, smartphones and advanced networking equipment, such as routers and servers, require the space-saving and sophisticated electronics that multi-layer PCBs offer. In the automotive sector, electronic control units (ECUs) benefit from the compact design of multi-layer PCBs, enabling efficient performance in limited spaces. According to a recent study, multi-layer PCBs accounted for over 60% of the global PCB market in 2023.

This dominance is attributed to the ongoing need for advanced electrical testing methods, such as solder joint inspection and impedance controlled routing, as well as thermal management solutions and high-speed design techniques like through-hole technology and surface mount technology. The PCB design process encompasses various stages, including design for manufacturing, PCB layout software, and component placement accuracy, to ensure the production of defect-free boards. PCB manufacturing involves various processes, such as the fabrication process, PCB assembly process, and automated optical inspection, to deliver high-quality products. Ultimately, the PCB market is driven by the constant pursuit of miniaturization, improved functionality, and enhanced performance in electronic devices.

The Multi-layer segment was valued at USD 22.00 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 88% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

See How Printed Circuit Board (PCB) Market Demand is Rising in APAC Request Free Sample

The market is experiencing significant growth, with APAC holding the largest market share during the forecast period. In 2024, China, Taiwan, South Korea, and Japan were the major revenue contributors and the largest markets for PCB in APAC. The expanding demand for electronics in the automotive, aerospace, and electronic and electrical industries, particularly in developing countries like China and India, is a primary growth driver. Furthermore, industrial development in countries such as China, India, South Korea, Indonesia, and Taiwan will necessitate high levels of automation in their respective industrial sectors.

According to recent reports, the global PCB industry is expected to witness substantial growth due to the increasing adoption of advanced technologies like HDI and Flex PCBs. This trend is expected to continue as the demand for miniaturization and lightweight electronics increases.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market is experiencing significant growth due to the increasing demand for advanced electronic devices. Automated Optical Inspection (AOI) technology plays a crucial role in identifying PCB defects, ensuring high product quality and reducing production costs. In high-speed digital PCB applications, signal integrity becomes a critical factor, with thermal vias significantly impacting PCB temperature and affecting performance. PCB design rules for high-frequency applications must be strictly adhered to, including minimizing EMI interference through thoughtful design techniques. Cost-effective PCB manufacturing processes are essential for businesses seeking to remain competitive in the market. Improving PCB assembly yield through automation is a key focus area, with advanced design software featuring process optimization techniques and real-time analysis capabilities. The effects of copper layer thickness on signal integrity are also a significant consideration, requiring careful material selection and design considerations. Effective PCB testing strategies are vital for identifying potential issues early in the production process. Root cause identification through failure analysis is a critical component of continuous improvement efforts. Advanced PCB design software features, such as 3D visualization and simulation tools, enable engineers to design for manufacturability and optimize the assembly process. Challenges associated with PCB miniaturization, including thermal management and component placement best practices, require innovative solutions. Methods for improving PCB thermal management, such as using advanced materials and designing heat sinks, are essential for maintaining optimal operating temperatures. Proper grounding techniques and effective use of different types of PCB surface finishes are also crucial for ensuring reliable performance. Using PCB design software effectively is a key competitive advantage, enabling businesses to quickly adapt to changing market demands and bring new products to market efficiently. The importance of proper PCB grounding techniques and component placement best practices cannot be overstated, as they directly impact the overall reliability and functionality of the final product.

What are the key market drivers leading to the rise in the adoption of Printed Circuit Board (PCB) Industry?

- The surge in smartphone adoption serves as the primary catalyst for market growth.

- The global smartphone market is experiencing significant growth, driven by the proliferation of affordable devices and expanding Internet connectivity in developing countries like India and China. This trend is fueled by the increasing disposable income and large populations of these nations. The evolution of smartphone technology continues, with the transition from 4G LTE to 5G networks. The implementation of 5G RF front ends in smartphones necessitates more space due to the intricacy of massive Multiple-In Multiple-Out antenna systems. The data processed by 5G networks is projected to increase exponentially, necessitating larger battery capacities.

- To accommodate these requirements, High Density Interconnect (HDI) Printed Circuit Boards (PCBs) and other electronic components are being developed to achieve higher density, smaller form factors, and more complex processes. This ongoing technological advancement underscores the dynamic nature of the smartphone market and its applications across various sectors.

What are the market trends shaping the Printed Circuit Board (PCB) Industry?

- The increasing trend in business involves greater flexibility and automation within industries. Flexibility and industry automation are becoming more prevalent market tendencies.

- The automation of industries continues to advance as computers and machines assume control functions, driving competitiveness through optimized productivity, operation costs, product quality, and safety. Power consumption, with the increasing power density of electric equipment, becomes a significant concern. Printed Circuit Boards (PCBs) are crucial in ensuring efficient power consumption within compact applications. Moreover, the proliferation of collaborative robots (cobots), industrial robots, and drones is fueling industrial automation's expansion.

- This trend underscores the importance of PCBs in facilitating seamless power management and communication between components, ultimately enhancing the overall performance of automated systems.

What challenges does the Printed Circuit Board (PCB) Industry face during its growth?

- The growth of the industry is significantly impacted by the environmental concerns surrounding PCBs (polychlorinated biphenyls), a persistent organic pollutant that poses serious risks to human health and the environment. Efforts to mitigate the use and disposal of PCBs are essential to ensure sustainable industrial development.

- PCBs, or printed circuit boards, are integral components of various electronic devices. These boards consist of hazardous materials, including metals, plastics, ceramics, and copper, as well as epoxy resins containing a significant amount of chlorine. Historically, lead solders were used in PCBs, but the industry has shifted towards lead-free alternatives due to environmental concerns. The transition has led to a reduction in the level of toxicity associated with PCB disposal. However, disposing of PCBs remains a challenge. Before disposal, components must be removed from the board to prevent potential harm to the environment. Recycling PCBs is an option, but the process can result in increased temperatures, mechanical shocks, and delamination.

- A PCB without mounted components comprises approximately 40% metal, 30% plastic, and 30% ceramic. The PCB itself accounts for about 28 wt%. The evolving nature of the industry necessitates continuous adaptation to new technologies and environmental concerns, making the PCB market a dynamic and intriguing sector.

Exclusive Technavio Analysis on Customer Landscape

The printed circuit board (pcb) market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the printed circuit board (pcb) market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape of Printed Circuit Board (PCB) Industry

Competitive Landscape

Companies are implementing various strategies, such as strategic alliances, printed circuit board (pcb) market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

APCT - This subsidiary of the company specializes in manufacturing advanced printed circuit boards, including 2 and 4 layer variants, through Advanced Circuits. Their offerings cater to various industries, ensuring high-quality and efficient solutions.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- APCT

- China Circuit Technology Shantou Corp.

- Compeq Manufacturing Co. Ltd.

- Daedeok Electronics Co. Ltd.

- Dynamic Electronics Co. Ltd.

- Ibiden Co. Ltd.

- Jabil Inc.

- Korea Circuit Co. Ltd.

- NOK Corp.

- RAYMING TECHNOLOGY

- Shenzhen Kinwong Electronic Co. Ltd

- Shenzhen SenYan Circuit Co. Ltd.

- ShenZhen Wonderful Technology Co. Ltd

- Shenzhen Zhongxinhua Electronics Co. Ltd.

- Sumitomo Electric Industries Ltd.

- TTM Technologies Inc.

- Victory Giant Technology (Huizhou) Co. Ltd.

- Vishal International

- Zhen Ding Technology Holding Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Printed Circuit Board (PCB) Market

- In January 2024, Intel Corporation announced the launch of its new line of high-performance, low-power FPGA-based system-on-chips (SoCs) for the automotive industry, integrating printed circuit boards (PCBs) with advanced features to enhance safety and efficiency (Intel press release).

- In March 2024, Rogers Corporation, a leading PCB manufacturer, entered into a strategic partnership with Infineon Technologies AG to develop high-reliability PCBs for the automotive and industrial markets, aiming to expand their customer base and strengthen their market position (Rogers Corporation press release).

- In May 2024, Isola Group, a global PCB material supplier, secured a significant investment of USD150 million from Koch Industries to expand its manufacturing capacity and accelerate the development of advanced PCB materials (Bloomberg).

- In April 2025, the European Union introduced new regulations on the restriction of hazardous substances (RoHS) in electronic waste, including PCBs, to further reduce the environmental impact of e-waste and promote the adoption of greener technologies (European Union press release).

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Printed Circuit Board (PCB) Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

211 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6.2% |

|

Market growth 2025-2029 |

USD 26.8 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

5.8 |

|

Key countries |

Taiwan, US, Canada, Germany, UK, Italy, France, China, India, Japan, Brazil, Egypt, Oman, Argentina, KSA, and UAE |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

Research Analyst Overview

- The market continues to evolve, with innovative designs and technologies shaping its landscape. Flexible and rigid-flex PCBs, for instance, are gaining traction due to their ability to conform to complex shapes and reduce the number of connectors, thereby enhancing system miniaturization. Design for manufacturing (DFM) practices are increasingly important, with solder joint inspection and advanced PCB layout software ensuring optimal manufacturing outcomes. Copper layer thickness and electrical testing methods are crucial aspects of PCB design, ensuring power integrity and signal integrity. The importance of thermal management solutions is underscored by the growing use of high-performance components, with multilayer PCB design and advanced assembly processes enabling efficient heat dissipation.

- Power integrity analysis and signal integrity analysis are essential for high-speed PCB design, ensuring reliable data transmission. PCB lifespan prediction and component placement accuracy are critical for maintaining product reliability, with PCB schematic capture and Gerber files enabling precise design and manufacturing. Surface mount technology and automated optical inspection streamline the manufacturing process, while through-hole technology remains relevant for certain applications. Industry growth in the PCB market is robust, with expectations of over 7% annual expansion driven by advancements in technology and increasing demand for miniaturized, high-performance electronics. For instance, a leading smartphone manufacturer reported a 30% increase in sales due to the adoption of advanced PCB designs.

- The importance of PCB material selection, via design, impedance-controlled routing, and functional testing methods cannot be overstated, as they directly impact the overall performance and reliability of electronic systems.

What are the Key Data Covered in this Printed Circuit Board (PCB) Market Research and Growth Report?

-

What is the expected growth of the Printed Circuit Board (PCB) Market between 2025 and 2029?

-

USD 26.8 billion, at a CAGR of 6.2%

-

-

What segmentation does the market report cover?

-

The report is segmented by Type (Multi-layer, HDI, Single sided, and Double sided), End-user (Communication network infrastructure, IT and peripherals, Automotive, Consumer electronics, and Others), Geography (APAC, North America, Europe, Middle East and Africa, South America, and Rest of World (ROW)), Substrate (FR-4 (Flame Retardant 4), Polymide, Metal Core, and Others (Ceramic, PTFE, etc.)), and Organization Size (Small and Medium Enterprises (SMEs) and Large Enterprises)

-

-

Which regions are analyzed in the report?

-

APAC, North America, Europe, Middle East and Africa, and South America

-

-

What are the key growth drivers and market challenges?

-

Rising adoption of smartphones, Environmental concerns regarding PCBs

-

-

Who are the major players in the Printed Circuit Board (PCB) Market?

-

APCT, China Circuit Technology Shantou Corp., Compeq Manufacturing Co. Ltd., Daedeok Electronics Co. Ltd., Dynamic Electronics Co. Ltd., Ibiden Co. Ltd., Jabil Inc., Korea Circuit Co. Ltd., NOK Corp., RAYMING TECHNOLOGY, Shenzhen Kinwong Electronic Co. Ltd, Shenzhen SenYan Circuit Co. Ltd., ShenZhen Wonderful Technology Co. Ltd, Shenzhen Zhongxinhua Electronics Co. Ltd., Sumitomo Electric Industries Ltd., TTM Technologies Inc., Victory Giant Technology (Huizhou) Co. Ltd., Vishal International, and Zhen Ding Technology Holding Ltd.

-

Market Research Insights

- The market is a dynamic and ever-evolving industry, characterized by continuous advancements and innovations. Two significant aspects of this market are the increasing demand for higher quality and reliability, and the ongoing efforts to reduce costs. For instance, the adoption of advanced quality control measures, such as rigorous reliability testing and improved reflow soldering techniques, has led to a notable sales increase of over 15% in the PCB manufacturing sector. Furthermore, industry experts anticipate a growth rate of approximately 6% in the PCB market over the next few years, driven by the expanding electronics industry and the increasing complexity of electronic devices.

- These trends reflect the industry's commitment to addressing the challenges of PCB manufacturing, including improving yield, optimizing design, and ensuring consistent performance under various environmental conditions. By focusing on these areas, the PCB market continues to adapt and thrive in the face of evolving technology and customer demands.

We can help! Our analysts can customize this printed circuit board (pcb) market research report to meet your requirements.