Sandblasting Media Market Size 2024-2028

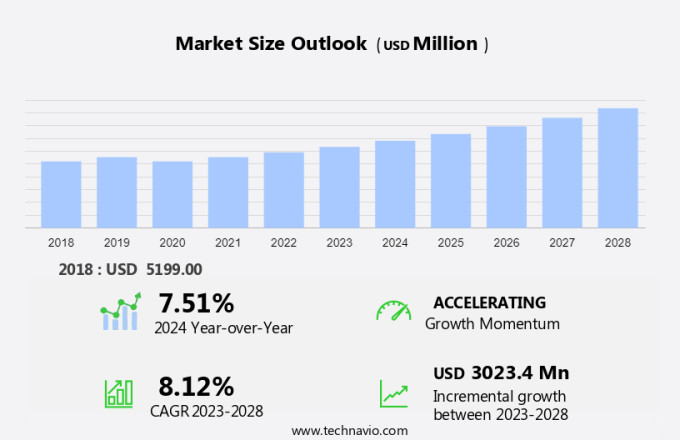

The sandblasting media market size is forecast to increase by USD 3.02 billion at a CAGR of 8.12% between 2023 and 2028.

- The market is experiencing significant growth due to the rapid expansion of industries such as aerospace, healthcare, and furnishing. These sectors are increasingly adopting sandblasting techniques for surface preparation and finishing, driving market demand. Sandblasting media is used in various industries, including manufacturing, construction, and solid waste management, for applications such as rust removal, coating preparation, and surface cleaning. Recyclable media, including soft metals, wood, fiberglass, stone, plastic, and composition materials, are gaining popularity for their eco-friendliness. Additionally, the leveraging of e-commerce platforms to increase market penetration and the growing use of automation in sandblasting processes are key trends propelling market growth. Automation not only enhances efficiency but also reduces labor costs and ensures consistent quality. Overall, these factors are expected to fuel market expansion in the coming years.

What will the size of the market be during the forecast period?

- The market is witnessing significant advancements driven by the increasing demand for efficient and cost-effective surface preparation solutions in various industries. Sandblasting media, also known as abrasive media, is used to clean and prepare surfaces for painting, rust removal, and other industrial processes. Several factors are contributing to the growth of the market. The manufacturing sector, particularly in the production of concrete and automotive industries, relies heavily on sandblasting media for surface preparation. In addition, the petrochemical industry utilizes sandblasting media for rust removal and etch surface profile enhancement. Automation technologies have gained popularity in the market due to their ability to improve manufacturing lead times and reduce labor costs. Automated data collection and automated blast control systems are increasingly being adopted to optimize production processes and ensure consistent quality. The market offers a wide range of media types, including glass beads, silica abrasives, metal grit, coal stag, and air devices. The choice of media depends on the specific application and the Mohs hardness scale of the surface being prepared. Recyclable media options are also available, making sandblasting a more sustainable process.

- Advanced technology has led to the development of hard programs and automatic floor remedy systems, which can significantly increase productivity and reduce downtime. These systems allow for precise control of the sandblasting process, ensuring optimal surface preparation results. In the realm of sandblasting media, rust removal is a critical application. Sandblasting media effectively removes rust, leaving a clean and prepared surface for coating applications. The use of sandblasting media in rust removal is particularly important in industries such as construction, where structures may have been exposed to the elements for extended periods. The market is expected to continue growing due to its versatility and efficiency.

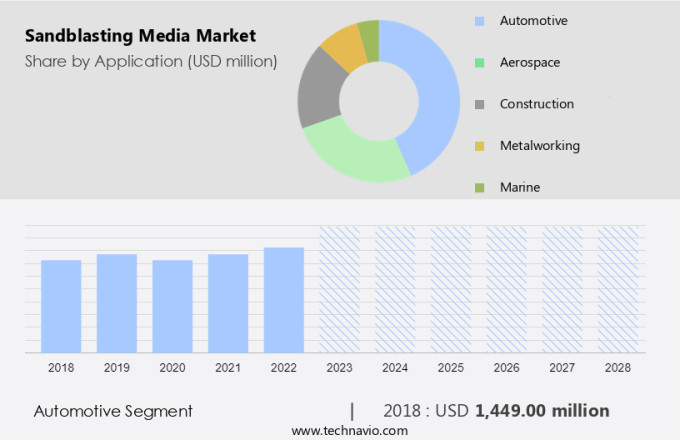

How is this market segmented and which is the largest segment?

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Automotive

- Aerospace

- Construction

- Metalworking

- Marine

- Product

- Aluminum oxide

- Si sand

- Steel shot

- Glass

- Others

- Geography

- North America

- US

- APAC

- China

- India

- Europe

- Germany

- UK

- South America

- Middle East and Africa

- North America

By Application Insights

- The automotive segment is estimated to witness significant growth during the forecast period.

The market encompasses a wide range of materials used for etching surface profiles in various industries. Long-lasting media, such as refractories and angular shapes like walnut shells, are commonly utilized due to their durability and effectiveness. De-burring, de-flashing, casting, molding, and production of electrical parts, automotive parts, turbines, and aircraft engines are key applications. Fine metals like steel, aluminum, copper, and zinc are often targeted in the metalworking segment. Media options include sand, grits, coal stags, glass beads, and silica abrasives, catering to construction activities and hard programs. Automatic floor remedies and production industry processes further expand the market scope.

Consequently, the automotive industry will continue to generate significant demand for sandblasting media in the coming years. This media is primarily used for surface finishing and vehicle polishing, as well as in the refurbishment of used vehicles. Other types of media, such as sodium bicarbonate, corn cob, staurolite, coal slag, copper slag, Si sand, garnet, dry ice, iron slag, nut shells, and various slags, are also employed in diverse applications based on their unique properties. Sandblasting media is an essential component in the manufacturing process, contributing to the production of high-quality metal products.

Get a glance at the market report of share of various segments Request Free Sample

The automotive segment was valued at USD 1.45 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

- APAC is estimated to contribute 35% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

The market encompasses a wide range of materials used for etching surface profiles in various industries. Long-lasting media, such as recycled walnut shells and angular refractories, are popular choices due to their durability and cost-effectiveness. Other media options include soft metals, wood, fiberglass, stone, plastic, and composition materials like Opta Minerals and Composition Materials. De-burring, de-flashing, casting, molding, and production of electrical parts, automotive parts, turbines, aircraft engines, and graffiti removal are key applications for these media. In the metalworking segment, steel, aluminum, copper, zinc, and other metal products are often processed using sand, grits, coal stags, and silica abrasives. Automatic floor remedies and hard programs in the construction industry also utilize these media for efficient and high-quality results. Glass beads and metal grit are common media choices for fine metals and hard materials, respectively.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in adoption of Sandblasting Media Market?

Rapid growth in aerospace, healthcare, and furnishing industries is the key driver of the market.

- The expansion of numerous industries, particularly automotive, construction, pharmaceutical, and furniture, fuels the significant growth of The market. The increasing usage of sandblasting media in the automotive, aerospace, and marine industries is a major catalyst for market growth. In the healthcare sector, micro-sandblasting is a valuable method for cleaning intricate components in medical devices, making it an essential process in the manufacturing of medical equipment. With the healthcare sector's continuous growth due to a growing global population and technological advancements, the demand for sandblasting media will correspondingly increase in this sector. Sandblasting media is widely used in construction activities for surface preparation and finishing, with hard programs relying on this process for automatic floor remedies.

- The production industry also heavily utilizes sandblasting media for coating removal and application, especially in the manufacturing of metal products. Various types of sandblasting media, including glass beads, silica abrasives, metal grit, coal stag, and others, cater to diverse applications. Air devices are commonly used to propel the media at high velocities, ensuring effective cleaning and surface preparation. Rust removal and coating application are significant applications of sandblasting media, making it an indispensable tool in various industries.

What are the market trends shaping the Sandblasting Media Market?

Leveraging e-commerce to increase market penetration is the upcoming trend in the market.

- Over the past few decades, the global population has experienced significant shifts in business and trade, with an increasing number of individuals in developing and underdeveloped countries gaining access to the internet via smartphones. This trend is anticipated to continue at an accelerated pace throughout the forecast period. The burgeoning e-commerce sector has opened up a wealth of opportunities for businesses across various industries, leading many market players to adopt advanced technologies to engage consumers, sell their products, and gather valuable insights into consumer behavior and preferences. Home improvement projects, for instance, have seen a wave in online sales, with sandblasting media being among the popular items.

What challenges does Sandblasting Media Market face during the growth?

The growing use of automation is a key challenge affecting the market growth.

- The market is experiencing significant changes due to the increasing adoption of automated or robotic blasting approaches in various industries, including aerospace and automobile sectors. These industries prioritize worker safety and efficiency, leading to the implementation of regulations and the shift toward robotic blasting mechanisms. This trend poses a challenge to the market growth as manual blasting techniques are gradually being replaced. Automation is revolutionizing numerous sectors, such as oil and gas, construction, manufacturing, and chemicals. By integrating robotic systems, companies enhance productivity, reduce labor costs, and improve overall performance. Furthermore, the integration of robotic blasting techniques enables the emergence of new business models and services, such as 3-dimensional signage with a hand-crafted or carved look.

- The use of sandblasting media comes with potential health threats, particularly for workers exposed to silica dust. As a result, it is essential for companies to invest in portable machines and follow safety guidelines to mitigate these risks. Additionally, the removal of paint and mill scale residues using sandblasting media plays a crucial role in repair and maintenance processes. In conclusion, the market is undergoing a transformation, driven by the need for improved safety, efficiency, and productivity. The integration of robotic blasting systems in various industries is a significant trend, and companies that adapt to this change will have a competitive edge.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABShot Tecnics SL

- BLASTECH

- Compagnie de Saint Gobain

- Crystal Mark Inc

- Donaldson Co. Inc.

- Eisenwerk Wurth GmbH

- ENVIRI CORP

- GMA Garnet Pty Ltd

- Graco Inc.

- Green Diamond

- Guyson Corp.

- Industrial Quick Search Inc.

- Kramer Industries Inc.

- Midwest Finishing Systems Inc.

- Opta Group LLC

- PAUL AUER GMBH

- SWARCO AG

- Synco Industries Ltd.

- The Chemours Co.

- U.S. Minerals

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a wide range of materials used for surface preparation and finishing in various industries. These media include advanced technologies like automated data collection, recovery, and blast control, as well as mechanical impact devices such as sandblasting machines. The market caters to sectors like petrochemical, construction, global tourism, and cultural heritage, with media options ranging from aluminum oxide, silicon carbide, steel grit, and steel shot to glass, sodium bicarbonate, corn cob, staurolite, coal slag, copper slag, si sand, garnet, dry ice, iron slag, nut shells, and more. The market serves the metalworking industry, military, and manufacturing sectors, with applications including rust removal, etch surface profile, and de-burring.

Additionally, recyclable, angular, long-lasting media are preferred for their cost-effectiveness and environmental sustainability. The market also offers refractories, walnut shell, and international trade standard compliant media for soft metals, wood, fiberglass, stone, plastic, and other materials. The automation technologies in sandblasting have significantly reduced manufacturing lead times and improved production efficiency. The market caters to industries like automotive, aerospace, and graffiti removal, with robotic blasting systems offering a hand-crafted or carved look for 3-dimensional signage. However, it's essential to consider health threats like silicosis and respiratory disorders when using certain media like silica abrasives. The market also offers media for specific applications like concrete, castings, molding, electrical parts, automotive parts, turbines, and aircraft engines.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

160 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 8.12% |

|

Market Growth 2024-2028 |

USD 3.02 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

7.51 |

|

Key countries |

US, China, Germany, India, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across North America, APAC, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch