3D Printer Market Size 2025-2029

The 3D printer market size is forecast to increase by USD 280.8 billion at a CAGR of 50.8% between 2024 and 2029.

- The market is experiencing significant growth, driven by the increase in consumer demand for customized products and the expanding applications in various industries. Industrial printing, particularly in sectors such as automotive, aerospace, and healthcare, is witnessing a shift towards additive manufacturing due to its ability to produce complex components with minimal tooling requirements. New materials, including ceramics and acrylonitrile butadiene styrene (ABS), are being explored for their unique properties, expanding the market's scope. Moreover, the market is witnessing a rise in the adoption of 3D printing technology in consumer electronics, jewelry, printed electronics, and diodes. The production of medical devices, textiles, valves, and other intricate components is also gaining traction.

What will be the Size of the 3D Printer Market During the Forecast Period?

- The 3D printing market encompasses the production and application of 3D printing technologies, primarily focused on layer-by-layer addition of materials based on three-dimensional files. This market has gained significant traction across various industry verticals, including healthcare, automotive, and consumer goods, due to its ability to produce complex geometries and prototypes with minimal process downtime. Traditional manufacturing processes, such as injection molding and CNC machining, face increasing competition from 3D printing in areas like rapid prototyping and the production of customized parts. 3D printing is revolutionizing industries, particularly in medical devices, where it enables the creation of intricate designs and customized solutions.

- The market's growth is driven by the adoption of standard process controls, safety and quality measures, and the increasing use of mixed materials, such as ceramics and composites, in 3D printing. The integration of 3D printing technologies with circuit boards and other advanced materials continues to expand its applications, further solidifying its role in manufacturing processes.

How is this 3D Printer Industry segmented and which is the largest segment?

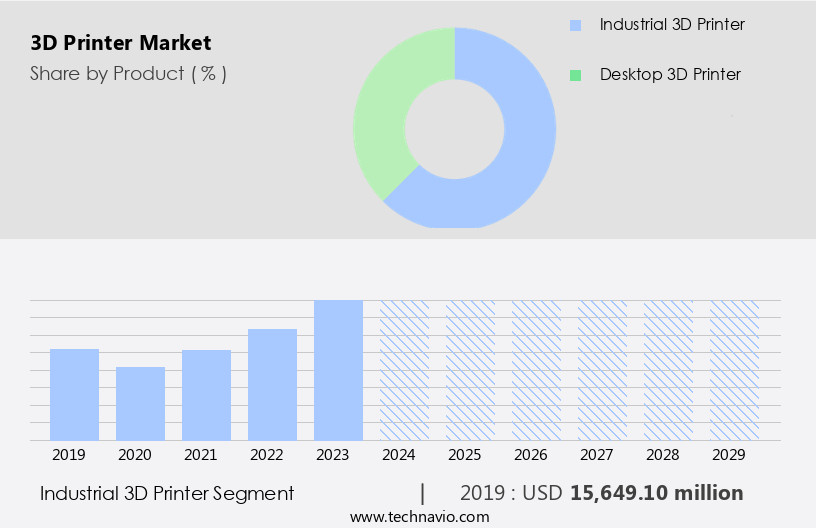

The 3D printer industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Product

- Industrial 3D printer

- Desktop 3D printer

- Technology

- Fused deposition modeling

- Selective laser sintering

- Stereolithography

- Others

- Material

- Polymer

- Metal and ceramic

- Geography

- North America

- Canada

- US

- Europe

- Germany

- UK

- France

- Italy

- APAC

- China

- Japan

- South Korea

- South America

- Middle East and Africa

- North America

By Product Insights

- The industrial 3D printer segment is estimated to witness significant growth during the forecast period.

The market is experiencing significant growth due to the increasing adoption of additive manufacturing technologies in various industries. Industrial 3D printers hold the largest market share, driven by their application in prototyping, tooling, and manufacturing complex components in sectors like aerospace, automotive, and healthcare. In aerospace, 3D printing is revolutionizing the industry by enabling the production of intricate parts such as jet engines, injectors, and valves, which are challenging to manufacture using traditional methods. This technology's benefits, including rapid prototyping, customization, and reduced production expenses, are fueling its demand in industries requiring high precision, durability, and low-cost solutions.

Get a glance at the market report of share of various segments Request Free Sample

The industrial 3D printer segment was valued at USD 15.65 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

- Europe is estimated to contribute 42% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The 3D printing market in North America is experiencing significant growth due to increased government investments and expanding applications in industries such as aerospace and defense, consumer electronics, and healthcare. The region's high potential for additive manufacturing has attracted market participants to form strategic partnerships and establish production facilities for cost-effective metal component production. The healthcare sector's demand for customized medical devices and the automotive industry's need for prototyping and tooling are major factors driving the market's growth. Three-dimensional printing technologies, including stereolithography and selective laser sintering, are used for prototyping applications and industry verticals, such as jewelry, education, and textiles.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of 3D Printer Industry?

Increase in consumer interest in 3D customized products is the key driver of the market.

- The 3D Printing Market encompasses the layer-by-layer addition of digital design files to create three-dimensional objects. This technology has gained significant traction in various industry verticals, including healthcare, automotive, aerospace, and education fields. Prototyping applications, such as creating medical devices, injection molding molds, and CNC machining jigs and fixtures, have been major drivers of the 3D Printing Market's growth. Stereolithography, selective laser sintering, and fused deposition modeling are some of the most common printing technologies used in the market. Customers seek the benefits of 3D printing, such as rapid prototyping services, high precision, durability, and the ability to print with various materials like plastics, metals, ceramics, composites, and circuit boards.

- The 3D Printing Market offers consultation solutions, installation services, and patenting assistance to businesses looking to invest in 3D printers. The adoption of this technology has led to a reduction in production expenses, as well as increased efficiency and customization. Standard process controls ensure safety and quality, while adherence to industry standards ensures suitability for various applications. Despite the benefits, challenges such as porosity, powder composition, morphology, and printed electronics' reliability remain. The market is experiencing growth through innovation, with developments in mixed materials, accuracy, reproducibility, and standardized tests. The marketplace caters to various industries, including defense, tooling, textiles, footwear, food and culinary, art and architecture, and electronics.

What are the market trends shaping the 3D Printer Industry?

Growing demand for new materials is the upcoming market trend.

- The 3D Printing Market is experiencing significant growth due to the increasing adoption of this technology in various industry verticals. Prototyping applications, particularly in industries like healthcare, automotive, and aerospace, are driving the demand for advanced 3D printing technologies such as Stereolithography and Selective Laser Sintering. The need for customized production, improved efficiency, and reduced process downtime is leading industries to explore new materials with superior mechanical properties, high precision, and durability. These materials are essential for producing parts with complex geometries and intricate details, which are difficult to achieve through traditional manufacturing processes like Injection molding and CNC machining.

- In the healthcare sector, 3D printing is being used to create medical devices, hearing aids, and even prosthetics, necessitating materials that are biocompatible, sterilizable, and have the ability to replicate the intricacies of human anatomy. The automotive industry is utilizing 3D printing for tooling, jigs, and fixtures, requiring materials with high strength and temperature resistance. In the aerospace industry, 3D printing is being used to create lightweight and high-strength components, necessitating materials with excellent thermal and electrical conductivity. The 3D Printing Market is expected to grow further as new materials are developed to meet the specific needs of various industries.

What challenges does the 3D Printer Industry face during its growth?

High cost of training workforce is a key challenge affecting the industry growth.

- The 3D Printing Market encompasses various industries, including prototyping, healthcare, automotive, and aerospace, among others. Three-dimensional printing, also known as additive manufacturing, utilizes layer-by-layer addition of a three-dimensional file to create physical objects. Stereolithography is one of the most common printing technologies used in this market. Prototyping applications are a significant industry vertical, with rapid prototyping services offering customized production and process downtime reduction. The healthcare sector benefits from 3D printing in creating medical devices, hearing aids, and even structural electronics. The automotive industry uses 3D printing for tooling, jigs, and fixtures, while aerospace relies on it for high-precision, durability, and mixed materials.

- The 3D Printing Market offers consultation solutions, installation services, and patenting assistance to businesses. Standard process controls ensure safety and quality, while adherence to standards is crucial for suitability in various industry applications. Printing technologies include Stereolithography, Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Selective Laser Melting (SLM). The marketplace caters to various materials, such as plastics, metals, ceramics, composites, circuit boards, and even printed electronics. The accuracy, reproducibility, and standardized tests ensure the suitability of these materials for various applications. The market offers low-cost 3D printers for businesses and consumers, making it accessible to a broader audience.

Exclusive Customer Landscape

The 3D printer market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the 3D printer market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, 3d printer market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

3D Systems Corp. - The company offers 3D printers such as SLA 750, DMP Factory 500, DMP Flex 350, ProX 950 and ProJet 7000HD.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ANYCUBIC Technology Co. Ltd.

- Carbon Inc.

- Desktop Metal Inc.

- EOS GmbH

- Formlabs Inc.

- General Electric Co.

- HP Inc.

- JINHUA WANHAO SPARE PARTS CO. LTD

- LuxCreo Inc.

- Markforged Holding Corp.

- Nano Dimension Ltd.

- Organovo Holdings Inc.

- Shenzhen Creality 3D Technology Co. Ltd

- SLM Solutions Group AG

- Stratasys Ltd.

- voxeljet AG

- XYZPRINTING Inc.

- Zhejiang Flashforge 3D Technology Co. Ltd.

- Zortrax S.A.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The 3D printing market continues to experience significant growth and innovation in various industry verticals, driven by the ability to produce prototypes and customized parts with increased efficiency and reduced production expenses. Three-dimensional printing, also known as additive manufacturing, is a layer-by-layer addition process that utilizes digital design files to create physical objects. This technology has gained popularity in several sectors, including healthcare, automotive, aerospace, and industrial manufacturing, among others. In the healthcare industry, 3D printing is used to create medical devices, prosthetics, and hearing aids, offering improved accuracy, durability, and suitability for individual patients. In the automotive sector, 3D printing is used for prototyping and producing customized parts, reducing process downtime and enabling faster time-to-market.

In addition, the aerospace industry also benefits from 3D printing, as it allows for the production of high-precision components with complex geometries, which are difficult to manufacture using traditional methods such as injection molding or CNC machining. The use of 3D printing in the aerospace industry also results in lighter and stronger parts, leading to improved fuel efficiency and reduced production costs. The materials used in 3D printing include plastics, metals, ceramics, composites, and even mixed materials. The choice of material depends on the specific application requirements, such as mechanical properties, porosity, morphology, and printing technologies used. For instance, stereolithography is commonly used for printing jewelry and customized parts due to its high accuracy and reproducibility.

Moreover, the 3D printing marketplace is witnessing several developments, with businesses offering installation services, consultation solutions, and patenting services to help customers optimize their use of 3D printing technology. The market is also seeing the emergence of low-cost 3D printers, making this technology accessible to a wider audience. Safety and quality are critical considerations in the 3D printing industry. Adherence to standards and safety regulations is essential to ensure the reliability and durability of 3D-printed parts. Standard process controls and testing methods are used to evaluate the suitability of 3D-printed parts for various applications, including printed electronics, circuit boards, and solar cells.

Therefore, the 3D printing market is experiencing significant growth and innovation, driven by the ability to produce customized parts and prototypes with increased efficiency and reduced production expenses. The technology is being adopted across various industry verticals, including healthcare, automotive, aerospace, and industrial manufacturing, among others. The choice of material and printing technology depends on the specific application requirements, and safety and quality are critical considerations to ensure the reliability and durability of 3D-printed parts.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

217 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 50.8% |

|

Market growth 2025-2029 |

USD 280.8 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

35.1 |

|

Key countries |

US, Germany, China, UK, Canada, Japan, South Korea, France, Italy, and The Netherlands |

|

Competitive landscape |

Leading Companies, market growth and forecasting, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this 3D Printer Market Research and Growth Report?

- CAGR of the 3D Printer industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the 3D printer market growth of industry companies

We can help! Our analysts can customize this 3D printer market research report to meet your requirements.