Bowl Feeders Market Size 2025-2029

The bowl feeders market size is forecast to increase by USD 33.2 million, at a CAGR of 4.4% between 2024 and 2029.

- The bowl feeder market is experiencing significant growth, driven by the increasing demand in various end-user industries, including automotive, electronics, and food processing. This trend is attributed to the benefits offered by bowl feeders, such as increased productivity and efficiency in manufacturing processes. Moreover, the adoption of Industry 4.0 and smart factory solutions is fueling the demand for advanced bowl feeders with enhanced features such as sensors and data analytics capabilities. However, high costs associated with the acquisition and maintenance of bowl feeders pose a challenge for market participants. These costs can include the price of the equipment itself, as well as ongoing expenses for power consumption and maintenance.

- Companies seeking to capitalize on the market's opportunities must carefully consider these costs and explore ways to optimize their use of bowl feeders to maximize return on investment. Additionally, staying abreast of technological advancements in the field and adopting innovative solutions can help mitigate the impact of these costs and ensure long-term competitiveness. The market is experiencing significant growth due to the integration of Industry 4.0 technologies.

What will be the Size of the Bowl Feeders Market during the forecast period?

- In the dynamic bowl feeder market, system training and customized solutions are essential for ensuring optimal performance. Vibration adjustment and track alignment are critical components of system configuration, while feed rate monitoring and part defect detection help maintain industry standards. Bowl lubrication and track cleaning contribute to energy efficiency and sustainability practices. Custom engineering and integration services enable system optimization and seamless system integration.

- Part orientation control and safety standards are integral to part quality control, with environmental compliance and bowl replacement addressing wear and sustainability concerns. Part rejection systems and system support facilitate feed rate adjustment and system programming, ensuring the feeding control systems meet the evolving needs of businesses.

How is this Bowl Feeders Industry segmented?

The bowl feeders industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

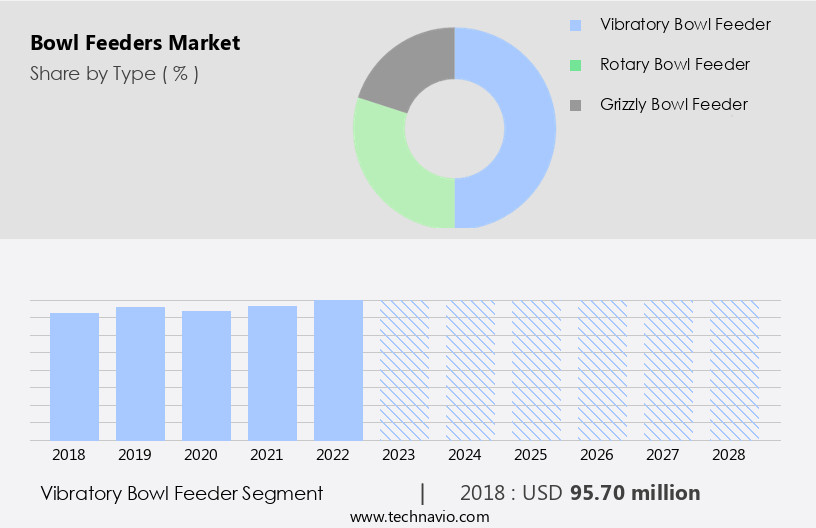

- Type

- Vibratory bowl feeder

- Rotary bowl feeder

- Grizzly bowl feeder

- Application

- Food

- Pharmaceutical

- Material handling

- Chemical

- Others

- End-user

- Large enterprises

- SMEs

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Type Insights

The vibratory bowl feeder segment is estimated to witness significant growth during the forecast period. Vibratory bowl feeders, a vital component in material handling systems, are gaining prominence in various industries, including automotive, electronics, and pharmaceuticals. These feeders employ vibration and gravity to move and align parts, ensuring precise feeding and orientation. Their significance lies in automated assembly lines, pick-and-place processes, and high-speed production environments, where accuracy, speed, and dependable part feeding are indispensable. The demand for vibratory bowl feeders is surging due to their efficiency and reliability. These feeders offer consistent feeding rates, precise part orientation, and effective part separation, making them a preferred choice for manufacturing automation. In the heavy equipment industry, they ensure seamless part delivery and minimize downtime.

In the plastic processing industry, they provide vibration control for handling delicate parts. Vibratory bowl feeders' versatility extends to various applications, such as medical device manufacturing and automated packaging. They cater to diverse part sizes, shapes, and materials, including metals and plastics. Their robust design ensures maintenance-free operation, while their cost-effectiveness makes them a popular choice for industrial automation. Bowl feeder design considerations include bowl diameter, depth, and material. Centrifugal bowl feeders and linear bowl feeders cater to different feeding requirements. Feeding rate control, part tolerance, and vibration amplitude are crucial factors in ensuring feeding efficiency and consistency.

The Vibratory bowl feeder segment was valued at USD 99.40 million in 2019 and showed a gradual increase during the forecast period.

Bowl feeder components, such as feed tracks and part presentation systems, contribute to the overall performance of the feeder. Vibration frequency and amplitude can be adjusted to optimize feeding performance. Robotic integration and part inspection systems further enhance the capabilities of vibratory bowl feeders. The market for vibratory bowl feeders is witnessing significant growth due to their ability to provide reliable, precise, and efficient part feeding and orientation solutions. Their adaptability to various industries and applications makes them an essential component of manufacturing automation.

The Bowl Feeders Market is growing due to the rising demand for automated bowl feeders in production automation. These systems enhance feeding accuracy by precisely handling various part sizes, part weights, part shapes, and part materials. Efficient feed track design, including optimized track material and track design, ensures smooth movement. Proper bowl depth and controlled bowl vibration allow effective durable feeding, minimizing part damage. Bowl feeder applications span automotive, electronics, and pharmaceuticals, requiring consistent part surface handling. Regular bowl feeder maintenance ensures longevity and performance. The market favors innovations that refine feed track efficiency and track design, ensuring reliable automation. As industries advance, optimized track material selection continues to drive improvements in feeding solutions.

Regional Analysis

APAC is estimated to contribute 36% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in the APAC region is experiencing substantial growth, driven by the expanding manufacturing and industrial sectors in countries like China, India, Japan, and South Korea. The increasing demand for efficient material handling solutions, coupled with technological advancements and the emphasis on automation and robotics in industries such as automotive, electronics, and food processing, are key factors fueling market growth. Bowl feeders are integral to industries seeking to enhance production efficiency and accuracy, making them a popular choice for applications in manufacturing processes. In the APAC region, the strong focus on industrial development, coupled with rising disposable income and changing consumer preferences, positions it as a lucrative market for bowl feeders.

Centrifugal bowl feeders, rotary bowl feeders, and linear bowl feeders are commonly used in various industries for part feeding systems. These feeding solutions offer reliable feeding, material feeding, and feeding rate control, ensuring part presentation and orientation for further processing. Precision feeding and part inspection are essential for industries such as plastic processing and medical device manufacturing, where part tolerance and part separation are critical. Bowl feeder design and components, including bowl material, track configuration, and vibration control, are essential considerations for manufacturers seeking cost-effective feeding solutions. Industrial automation, assembly lines, and automated packaging lines are some of the applications where bowl feeders are extensively used for part handling and feeding capacity.

The heavy equipment industry, metalworking industry, and manufacturing equipment sectors also rely on bowl feeders for part delivery, ensuring high-speed feeding and feeding consistency for production lines. Robotic integration and part sorting are essential features in modern manufacturing processes, making bowl feeders an indispensable component of automation equipment. Smart manufacturing and digital twin technologies enable real-time remote monitoring, predictive maintenance, and material traceability, while noise reduction and amplitude control cater to safety features.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Bowl Feeders market drivers leading to the rise in the adoption of Industry?

- The significant increase in demand for bowl feeders in various industries serves as the primary market driver. Bowl feeders are essential components of automation equipment in various industries. By integrating a high-speed bowl feeder into production lines, businesses can experience increased productivity, decreased labor requirements, and improved product quality. The feeder's design ensures the material is delivered to an optimal work position, reducing ergonomic risks and enhancing efficiency. Bowl feeders offer operational flexibility with their ability to handle different part sizes and shapes, as well as varying throughput rates.

- Maintaining a bowl feeder is hassle-free due to its maintenance-free feeding mechanism. The bowl material and track configuration are engineered for durability, ensuring minimal downtime. The feed rate can be adjusted to accommodate varying production demands, making these feeders an indispensable asset for industries seeking to streamline their manufacturing processes. Their design caters to the weight of transported materials and the specific packaging formats. These feeders can be configured with various track designs and vibration amplitudes to accommodate part presentation and ensure seamless integration with packaging lines and robotic systems.

What are the Bowl Feeders market trends shaping the Industry?

- The adoption of Industry 4.0 is gaining significant traction in the market, representing a prominent trend in the business world. This technological advancement, characterized by the integration of smart factories, automation, and data-driven processes, is becoming increasingly prevalent.

- Advanced bowl feeders equipped with sensors and connectivity capabilities enable real-time monitoring of critical parameters such as vibration levels, component flow rate, and power consumption. This data allows manufacturers to identify potential issues and perform predictive maintenance, minimizing downtime and unexpected breakdowns. Moreover, Industry 4.0 facilitates seamless integration between bowl feeders and other automated systems, such as robotics and conveyor belts.

How does Bowl Feeders market face challenges during its growth?

- The high costs linked to bowl feeder systems represent a significant challenge impeding the expansion of the industry. Bowl feeders are a crucial component of material handling systems in various industries, particularly those with high-volume requirements. These feeding systems, which include centrifugal and rotary designs, enable process automation and precision feeding of parts. Bowl feeder operation relies on the diameter of the bowl and the feeding rate control to ensure accurate part handling and orientation.

- Consequently, industries that can significantly benefit from the implementation of bowl feeders, such as the heavy equipment industry, invest in these systems. The mineral processing sector, for example, utilizes bowl feeders to facilitate the smooth transfer of materials and finished products. Overall, the high cost of bowl feeders is justified by their ability to streamline manufacturing processes and improve productivity. While these features enhance functionality, they also increase costs, including maintenance and sanitation expenses.

Exclusive Customer Landscape

The bowl feeders market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the bowl feeders market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, bowl feeders market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Ars srl - The company specializes in Bowl Feeders, including FlexiBowl, an innovative flexible parts feeding system that redefines manufacturing efficiency and automation standards.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Ars srl

- Automation Devices Inc.

- California Vibratory Feeders Inc.

- CDS Manufacturing

- DEPRAG SCHULZ GMBH u. CO. KG

- Elscint India Pvt. Ltd.

- Emerson Electric Co.

- Fortville Feeders Inc.

- Hoosier Feeder Co.

- Moorfeed Corp.

- Orientech Automation Solutions

- PCE Automation Ltd.

- Performance Feeders Inc.

- REVO Integration Sdn. Bhd.

- Rhein Nadel Automation GmbH

- Suzhou Huilide Machine Co. Ltd.

- TECNICAS DE ALIMENTACION DINAMICA SL

- The Arthur G. Russell Co. Inc.

- Vibratory Feeders Inc.

- WEBER Schraubautomaten GmbH

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Bowl Feeders Market

- In February 2023, leading bowl feeder manufacturer, Schmalz Inc., introduced a new generation of bowl feeders, the TS series, featuring advanced servo technology and modular design for increased flexibility and efficiency (Schmalz Inc. Press release).

- In June 2024, Bosch Rexroth and FANUC Corporation announced a strategic partnership to integrate Bosch Rexroth's bowl feeders with FANUC robots, enhancing automation solutions for various industries (Bosch Rexroth press release).

- In October 2024, Jervis B. Webb Company, a leading material handling solutions provider, acquired the bowl feeder business of another prominent player, Dorner Manufacturing, expanding its product portfolio and market reach (Jervis B. Webb Company press release).

- In March 2025, the European Union approved new regulations for the food industry, mandating the use of hygienic bowl feeders to ensure food safety and quality, creating a significant demand for this technology in the region (European Commission press release).

Research Analyst Overview

In the dynamic and evolving world of manufacturing automation, bowl feeders continue to play a pivotal role in material handling systems, particularly in process automation and part feeding applications. These feeding systems, which include centrifugal bowl feeders and rotary bowl feeders, are integral components of manufacturing equipment, enabling the reliable feeding of parts with precision and accuracy. Bowl diameter and depth are essential factors in bowl feeder design, influencing feeding capacity and part presentation. Linear and vibratory bowl feeders employ different feeding mechanisms to ensure efficient and consistent feeding, with the latter utilizing vibration frequency and amplitude to separate and orient parts.

Bowl feeder components, such as feed tracks and bowl material, undergo constant refinement to enhance feeding efficiency, durability, and cost-effectiveness. The applications of bowl feeders span various industries, including the heavy equipment industry, plastic processing industry, medical device industry, and manufacturing automation. Part handling automation and part inspection are critical aspects of bowl feeder operation, ensuring part orientation, size, weight, and surface quality meet specifications. Vibration control and part delivery systems are essential features that contribute to the overall reliability and performance of these feeding systems. As manufacturing processes continue to evolve, bowl feeders remain a vital element in production lines, assembly lines, automated packaging, and machine tending, offering maintenance-free feeding and automated assembly capabilities.

The ongoing advancements in feeding technology ensure that bowl feeders continue to meet the demands of various sectors, delivering cost-effective, high-speed feeding solutions for a wide range of part sizes and shapes. The Bowl Feeders Market continues to evolve with innovations in custom design and custom manufacturing, meeting diverse industry needs. Proper track lubrication ensures smooth part movement, minimizing friction and reducing bowl wear. Effective vibration monitoring enhances performance, allowing precise control over feeding mechanisms. Regular bowl cleaning is essential to maintain operational efficiency and uphold stringent performance standards. As industries demand more durable solutions, optimizing feeder systems helps achieve long-term reliability.

Dive into Technavio's strong research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Bowl Feeders Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

221 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.4% |

|

Market growth 2025-2029 |

USD 33.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

4.2 |

|

Key countries |

US, China, India, Canada, Germany, UK, Japan, France, Italy, and South Korea |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Bowl Feeders Market Research and Growth Report?

- CAGR of the Bowl Feeders industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the bowl feeders market growth of industry companies

We can help! Our analysts can customize this bowl feeders market research report to meet your requirements.