Industry 4.0 Market Size 2025-2029

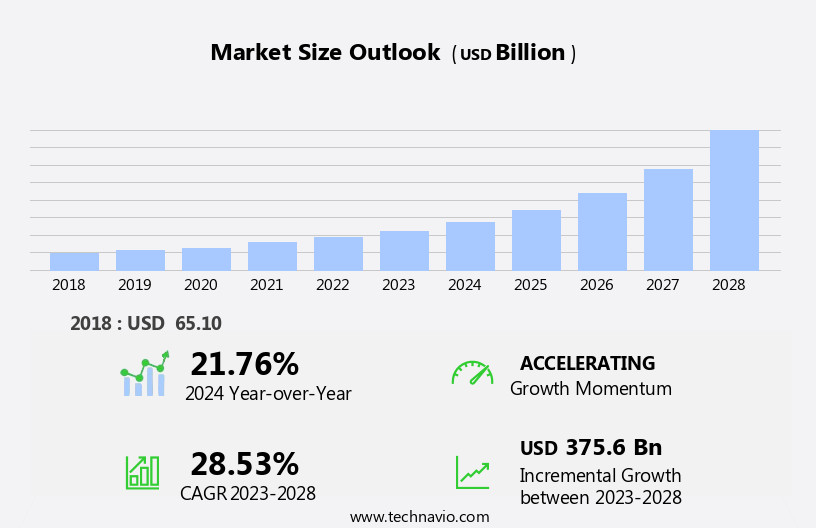

The industry 4.0 market size is forecast to increase by USD 471.6 billion at a CAGR of 29.1% between 2024 and 2029.

- The market is driven by the growing need for simplification in complex manufacturing activities. This trend is fueled by the increasing adoption of advanced technologies, such as virtualization of automation control systems, which enable real-time monitoring and optimization of production processes. Green technologies and climate change concerns are shaping the market, with an increasing focus on waste reduction and clean energy. However, the implementation of Industry 4.0 technologies presents several challenges. Technical hurdles, including interoperability issues and data security concerns, hinder the widespread adoption of these solutions.

- To navigate these challenges, organizations must invest in robust integration strategies and prioritize cybersecurity measures to ensure seamless data exchange and protection. Extended reality (XR) and digital twin technologies provide virtual representations of physical assets, enhancing operational efficiency and reducing downtime. By doing so, they can streamline their operations, enhance productivity, and ultimately, drive growth in the market. Companies must address these challenges to effectively capitalize on the opportunities presented by Industry 4.0 and remain competitive in the evolving manufacturing landscape.

What will be the Size of the Industry 4.0 Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2019-2023 and forecasts 2025-2029 - in the full report.

Request Free Sample

In the market, smart factories are revolutionizing manufacturing processes with advanced sensors, robotics, and machine learning. Customer support is enhanced through virtual representations and AI algorithms, enabling real-time monitoring and resource optimization. Real-time data processing from sensor networks drives clean energy solutions and waste recycling, aligning with sustainability initiatives. Cloud computing and enterprise systems facilitate supply chain efficiency, while edge computing and embedded software manage physical assets.

Sensor technologies and resource optimization play a crucial role in climate change mitigation efforts.The integration of 3D printing and AI algorithms in manufacturing processes further boosts efficiency and reduces waste. Overall, Industry 4.0 is transforming business operations with a focus on sustainability, efficiency, and real-time data processing.

How is this Industry 4.0 Industry segmented?

The industry 4.0 industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Application

- Industrial IoT

- Smart factory

- Industrial automation

- End-user

- Manufacturing

- Automotive

- Energy and utilities

- Oil and gas

- Others

- Component

- Hardware

- Software or platforms

- Services

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- Spain

- UK

- APAC

- China

- India

- Japan

- Rest of World (ROW)

- North America

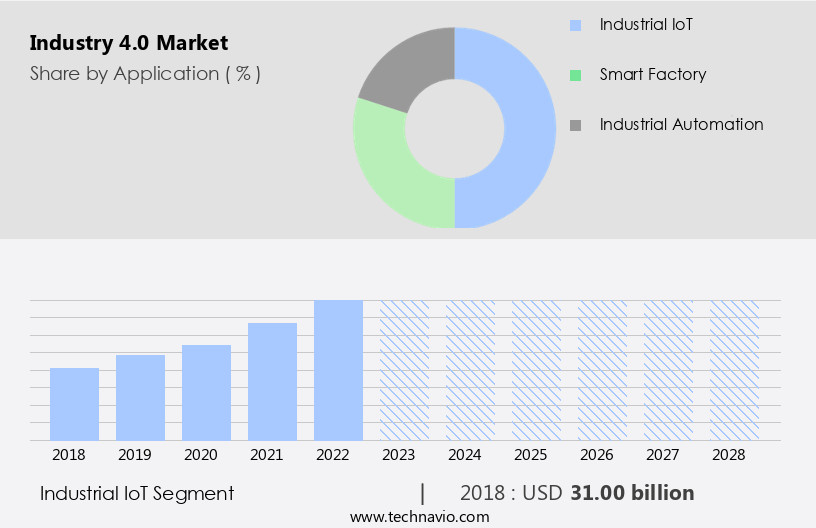

By Application Insights

The Industrial IoT segment is estimated to witness significant growth during the forecast period. In the evolving industrial landscape, the Internet of Things (IoT) is revolutionizing various sectors by connecting physical devices, machines, and sensors to the Internet for seamless data communication. This network of interconnected objects is transforming industries, from healthcare and transportation to manufacturing and energy, enabling real-time monitoring, predictive maintenance, and resource optimization. IoT devices integrated into manufacturing facilities streamline operations, reduce downtime, and enhance productivity by facilitating faster data transfer and automating repetitive tasks. Advanced sensors and machine learning algorithms help in continuous product quality improvement, while real-time data processing and Edge computing enable quicker decision-making. Cloud computing and collaborative solutions offer accessible training and medical research opportunities, while digitalization and automation in manufacturing plants ensure agile and lean production processes.

Moreover, the implementation of green infrastructure development, waste-to-energy solutions, and carbon emission tracking supports sustainability and environmental consciousness. The transformative potential of these technologies is evident in the automotive, aerospace, and defense industries, where the adoption of industrial robots, automated manufacturing systems, and predictive maintenance is driving innovation and efficiency. The integration of advanced sensors, AI algorithms, and real-time data analysis in various industries is paving the way for a more connected and intelligent future, where physical assets and virtual representations work together to optimize processes and improve overall productivity. The solar sector integrates data openness and predictive maintenance, while the manufacturing sector explores the potential of additive manufacturing and hybrid cloud.

The Industrial IoT segment was valued at USD 36.80 billion in 2019 and showed a gradual increase during the forecast period.

The Industry 4.0 Market is transforming global manufacturing with advanced industry automation and automated manufacturing facilities. Technologies enhancing tasks like welding, heavy lifting, ironing, assembling, palletizing, and product inspection are boosting efficiency and reducing unemployment. With increased data and connectivity, real-time data collection drives smarter operations and supports climate action by integrating greenam energy into smart grids like state grid networks. In healthcare, personalization enables tailored medical devices, improving patient adherence. Smart systems simulate human tissues for precise drug testing, while demand for components like ventilator valve demand rises in critical care. Industry 4.0 fosters sustainability, agility, and resilience reshaping every level of the industrial value chain through smart innovation.

The integration of 3D printing technology and customized drugs caters to personalized medical devices and pharmaceuticals. In the energy and utilities sector, renewable energy sources like wind, solar, and biomass are gaining popularity, with smart factories adopting green technologies and digital twin representations for efficient energy management and waste reduction. The automotive industry is also embracing the transformation, with the development of intelligent manufacturing systems and electric vehicles. Privacy and security concerns are addressed through advanced encryption and blockchain technology, ensuring data openness and connectivity standards for seamless integration and collaboration. The manufacturing sector's digital transformation is further aided by advanced robotics engineering, 5G connectivity, and the reskilling of the workforce.

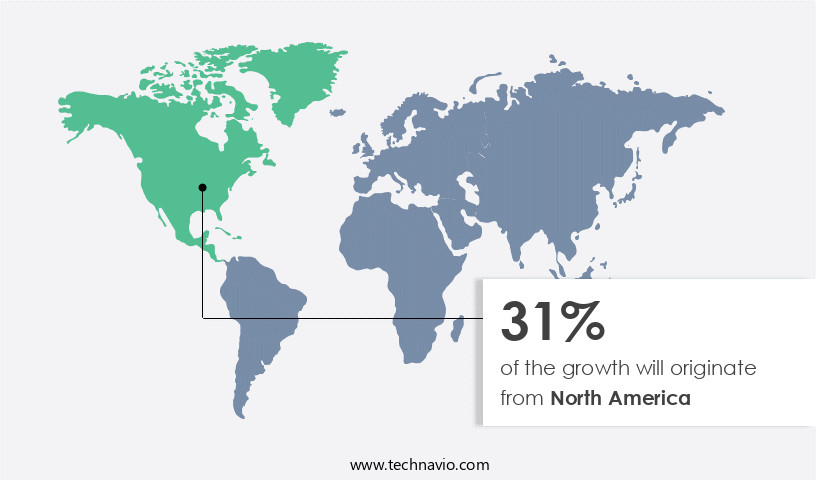

Regional Analysis

North America is estimated to contribute 30% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market is witnessing significant growth, particularly in North America, where a large portion of revenue is being generated. This region's dominance is due to its robust manufacturing sector, with key industries such as oil and gas, power, automotive, food and beverage, and pharmaceutical driving demand. In the US, coal-fired power plants are being replaced by natural gas-based alternatives, with the majority expected to transition by 2035. The availability of abundant shale oil and gas resources and low prices are fueling investments in chemical and petrochemical plants. The oil and gas industry's demand for industrial automation solutions is increasing due to the initiation of new chemical and petrochemical projects.

Sensor technologies, automation, and digitalization are transforming manufacturing facilities, enabling real-time monitoring, reduced downtime, and increased productivity. Advanced sensors, AI algorithms, and machine learning are being integrated into manufacturing plants, warehouses, and supply chains for predictive maintenance, continuous learning, and resource optimization. The automotive industry is embracing Industry 4.0 trends, with smart factories, 5G connectivity, and industrial robots revolutionizing production processes. The healthcare sector is also adopting personalized medicine, medical training, and surgical planning, while the renewable energy sector is focusing on biomass energy, solar, and wind power. Green infrastructure development and waste recycling are essential components of Industry 4.0, with a growing emphasis on sustainability and environmental footprint reduction.

The market's evolving patterns include the integration of human expertise, human-machine interaction, and collaborative solutions, addressing skills gaps and cultural resistance. The future of Industry 4.0 lies in the convergence of physical and digital assets, with cloud computing, Edge computing, and blockchain technology playing crucial roles. The transformative potential of Industry 4.0 is vast, impacting various sectors and industries, from manufacturing and automotive to healthcare and renewable energy.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Industry 4.0 market drivers leading to the rise in the adoption of Industry?

- The necessity of simplifying intricate manufacturing processes serves as the primary market catalyst. In today's industrial landscape, the integration of advanced technologies such as embedded software, cloud computing, and machine learning is transforming manufacturing processes. This shift towards Industry 4.0 is particularly relevant for asset-heavy industries like automotive, healthcare, and energy, where complex structures and real-time data processing are essential. Cloud computing enables data capture and analysis from various sources, facilitating collaborative solutions and intelligent manufacturing systems. Robotics engineering, additive manufacturing, and bioprinting are revolutionizing production processes, allowing for lean production and customized products. Moreover, the focus on sustainability is driving the adoption of green technologies such as renewable energy, biomass energy, and carbon emission tracking.

- However, the implementation of Industry 4.0 solutions faces challenges, including cultural resistance and rapid disintegration of traditional business models. Human expertise remains crucial in this evolving landscape, necessitating reskilling and upskilling efforts. In the supply chain, collaborative solutions and real-time data processing enable improved inventory management and predictive maintenance. Intelligent manufacturing systems and lean production techniques contribute to increased efficiency and reduced waste. The market presents significant transformative potential for asset-heavy industries.

What are the Industry 4.0 market trends shaping the Industry?

- Virtualization of automation control systems is an emerging market trend. This involves implementing virtualized environments to run and manage control systems, enhancing efficiency, flexibility, and reducing hardware costs. Industrial automation can be enhanced through the implementation of virtualization technology, which enables the creation and operation of virtual machines. These machines run an operating system and software, allowing for the efficient use of resources and cost savings on power consumption. Traditional physical servers, which can only run one operating system and application at a time, limit their performance. In the context of Industry 4.0, virtualization is particularly relevant for industries such as medical devices and food and beverages, where tailored solutions are required. This technology also facilitates advanced processes like picking and positioning, human-machine interaction, and real-time data analysis.

- Additionally, connectivity standards, such as blockchain technology, are crucial for ensuring data security and integrity in healthcare innovation and testing. The proficient workforce of the future will need to be skilled in the operation and maintenance of these advanced systems. Furthermore, industries like robotics, oil and gas, and the fertilizer industry can benefit from the customization and productivity gains offered by virtualization and automated manufacturing systems. Emissions reduction is another significant advantage, as virtualization minimizes the need for physical servers and reduces energy consumption. Product quality is also improved through the implementation of advanced sensors and AI algorithms, which enable predictive maintenance and preventative measures.

How does Industry 4.0 market faces challenges during its growth?

- The implementation of Industry 4.0 technologies in the industry presents significant technical challenges that can hinder its growth. These challenges must be addressed in a proficient and systematic manner to ensure the successful adoption and integration of these advanced technologies. The Industrial Internet of Things (IIoT) is revolutionizing manufacturing and factory automation, offering benefits such as real-time communication and distributed intelligence systems. IIoT enables smart maintenance, predictive analytics, and efficient industrial processes. However, the increasing adoption of IoT-enabled devices presents design challenges for manufacturers and system integrators. The factory automation process consists of three levels for control: field, control, and operator. The field level includes I/O modules, sensors, and actuators. The control level comprises PLCs, SCADA, motor drives, controllers, and DCS.

- Connected vehicles and smart factories are leveraging 5G connectivity and edge computing capabilities to optimize production and customer support. Manufacturing sectors like pharmaceuticals and aerospace and defense are embracing Industry 4.0, focusing on continuous learning, personalized medicine, and renewable power. Automotive manufacturers are integrating 5G, industrial robots, and 3D printing into their processes. Multi-tier manufacturing topology and employee training are essential for a successful Industry 4.0 implementation. Skills gaps can be addressed through automated tools and clean energy initiatives like sensor networks and predictive maintenance. The operator level encompasses HMIs. Data openness is crucial for IIoT in manufacturing, allowing for seamless communication between physical counterparts and enterprise systems.

Exclusive Customer Landscape

The industry 4.0 market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the industry 4.0 market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, industry 4.0 market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

ADLINK Technology Inc. - This company specializes in implementing Industry 4.0 technologies, including Cisco Edge Intelligence, to enhance manufacturing processes and optimize operations for businesses.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ADLINK Technology Inc.

- Advantech Co. Ltd.

- AURA DIFUSION S.L.

- Cisco Systems Inc.

- Cognex Corp.

- Emerson Electric Co.

- FANUC Corp.

- General Electric Co.

- Honeywell International Inc.

- Huawei Technologies Co. Ltd.

- MIDEA Group Co. Ltd.

- Mitsubishi Electric Corp.

- OMRON Corp.

- Qualcomm Inc.

- Robert Bosch GmbH

- Rockwell Automation Inc.

- SAP SE

- Schneider Electric SE

- Siemens AG

- Stratasys Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Industry 4.0 Market

- In January 2024, Siemens AG, a leading industrial automation company, announced the launch of MindSphere Edge, an extension of its MindSphere IoT operating system, designed to enable edge computing and decentralized data processing for Industrie 4.0 applications (Siemens AG press release, 2024).

- In March 2024, Bosch Rexroth and Microsoft Corporation formed a strategic partnership to integrate Microsoft Azure IoT services into Bosch Rexroth's industrial IoT solutions, aiming to enhance the connectivity and data processing capabilities for Industrie 4.0 applications (Bosch Rexroth press release, 2024).

- In May 2024, ABB Ltd, a global leader in industrial automation and robotics, secured a USD150 million investment from Caisse de depot et placement du Quebec (CDPQ) to expand its robotics and digital solutions business, further strengthening its position in the Industrie 4.0 market (ABB Ltd press release, 2024).

- In February 2025, the European Union unveiled the Digital Single Market Strategy for European Industry, which includes a focus on Industrie 4.0 and the adoption of advanced digital technologies, aiming to boost competitiveness and create new opportunities for European industries (European Commission press release, 2025).

Research Analyst Overview

The market continues to evolve, integrating various sectors with advanced technologies and systems. In energy and utilities, digitalization and automation reduce downtime and optimize resources, while in manufacturing, real-time data processing and edge computing enhance productivity and product quality. The food and beverages sector embraces customized production, and medical research benefits from human-machine interaction and AI algorithms. The ongoing unfolding of market activities is evident in the robotics industry, where automation and advanced sensors transform manufacturing facilities. In healthcare, intelligent manufacturing systems and connectivity standards foster innovation, while in the fertilizer industry, data capture and collaborative solutions optimize resource usage.

The renewable energy sector harnesses the transformative potential of blockchain technology and green technologies, while the automotive industry adapts to the challenges of lean production and cultural resistance. The oil and gas industry embraces digitization and automation, and the robotics industry continues to innovate with 5G connectivity and intelligent manufacturing systems. The employment landscape shifts with the rise of automation and reskilling, as industries adapt to the demands of Industry 4.0. In the complex structure of Industry 4.0, continuous learning and collaboration are essential.

The integration of physical and digital assets, from medical equipment to IoT devices, demands a proficient workforce and agile enterprise systems. The evolving patterns of Industry 4.0 promise a future of sustainability, efficiency, and innovation. Green infrastructure development, such as hybrid cloud and controlled configuration, is crucial for a sustainable and efficient industrial landscape. By embracing advanced technologies and adapting to the changing production landscape, businesses can enhance operational efficiency, reduce costs, and improve sustainability. Enterprise resource planning software rollouts can be streamlined through virtualization, ensuring captive use and seamless integration with other systems.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Industry 4.0 Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

223 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 29.1% |

|

Market growth 2025-2029 |

USD 471.6 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

23.6 |

|

Key countries |

US, China, Germany, Canada, Japan, UK, France, India, Italy, and Spain |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Industry 4.0 Market Research and Growth Report?

- CAGR of the Industry 4.0 industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the industry 4.0 market growth of industry companies

We can help! Our analysts can customize this industry 4.0 market research report to meet your requirements.