Broaching Machines Market Size 2024-2028

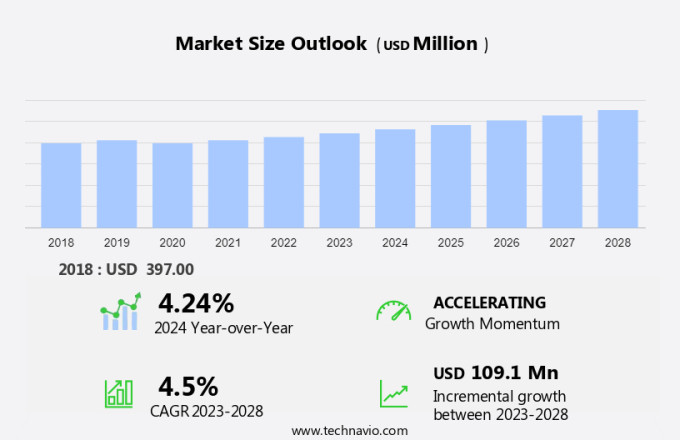

The broaching machines market size is forecast to increase by USD 109.1 million at a CAGR of 4.5% between 2023 and 2028. The market is experiencing significant growth due to the increasing demand for metal cutting solutions in various industries, particularly gear making and fabricated metal products. The integration of advanced technologies such as CNC controls, servo drives, and electro-mechanical actuators has enabled broaching machines to offer higher precision and productivity. Moreover, the collaboration of automation solution providers with broaching machine companies is further enhancing the capabilities of these machines. However, the market is also facing challenges, including price competition due to volatile input costs and the need for heavy industrial equipment maintenance. Hydraulic drives and ball screws continue to be popular choices for power transmission in broaching machines, while the adoption of CNC controls and high-performance motors is increasing.

What will be the Size of the Market During the Forecast Period?

The industrial manufacturing sector continues to evolve, with various processes playing a crucial role in shaping the industry's landscape. Among these processes, broaching machines have gained significant traction due to their ability to perform precise metal removal and surface finishing. Broaching machines are essential tools used in fabrication processes for manufacturing industries, including aerospace and defense, oil and gas, automotive, and heavy industrial applications. These machines come in two primary types: vertical and horizontal. Vertical broaching machines are designed to remove metal from a workpiece by moving a toothed instrument, called a broach, vertically.

Moreover, the broach is guided by a draw head or pulling head, while the workpiece remains stationary. This type of machine is suitable for producing complex shapes and contours in metal pieces. On the other hand, horizontal broaching machines employ a horizontal broach that moves across the workpiece, removing metal through the feed of the machine. This type is ideal for mass production and large-scale manufacturing. Both vertical and horizontal broaching machines are driven by motors, which can be hydraulic or electric. The hydraulic drive provides the necessary power for heavy-duty applications, while electric motors offer higher precision and flexibility.

Furthermore, the broaching process is essential in various industries, as it enables the production of high-quality, finished metal components. The automotive segment, for instance, relies on broaching machines for manufacturing critical parts such as gears, camshafts, and crankshafts. The industrial machinery sector, including small-scale firms, also benefits from broaching machines due to their ability to produce intricate parts with high accuracy and efficiency. Moreover, the integration of CAD systems and CNC technology has streamlined the manufacturing process, enhancing the overall productivity and competitiveness of firms. In conclusion, the market is a vital component of the industrial manufacturing sector.

Market Segmentation

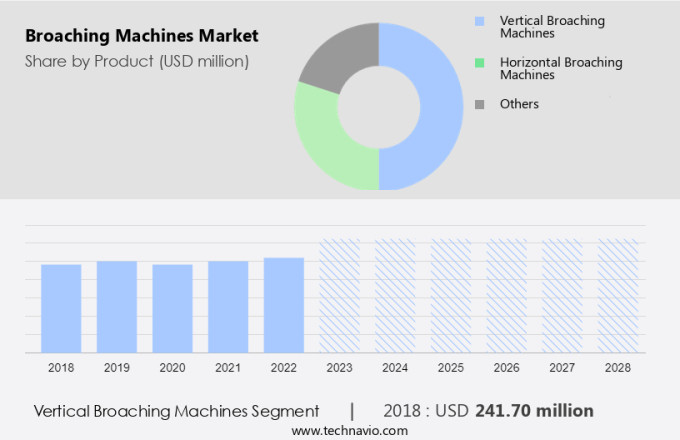

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Product

- Vertical broaching machines

- Horizontal broaching machines

- Others

- Geography

- Europe

- Germany

- UK

- APAC

- China

- Japan

- North America

- US

- South America

- Middle East and Africa

- Europe

By Product Insights

The vertical broaching machines segment is estimated to witness significant growth during the forecast period. Vertical broaching machines (VBM) come in two primary configurations: push and pull types. These machines are further divided into three categories: table-up, pull-up, and push-down. The most frequent application for VBMs is in metal cutting processes, particularly for gear making and fabricating various heavy industrial equipment. Two main power sources drive these machines: hydraulic and electromechanical. Hydraulic drives offer power and flexibility, while electromechanical actuators deliver precision and speed. Both types cater to diverse industry requirements. The table-up type of VBM has gained significant popularity in the metal processing industry due to its compatibility with modern, flexible manufacturing concepts.

Furthermore, its portable design and specialized re-tooling options make it an essential asset. In this setup, the broach remains stationary while the workpiece moves along it to achieve the desired shape. This configuration offers versatility and efficiency, making it a preferred choice for numerous manufacturing applications.

Get a glance at the market share of various segments Request Free Sample

The Vertical broaching machines segment accounted for USD 241.70 million in 2018 and showed a gradual increase during the forecast period.

Regional Insights

APAC is estimated to contribute 38% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

In Europe, the manufacturing industry continues to advance with significant investments in research and development (R&D) and supportive government initiatives. This dedication to innovation has resulted in the expansion of the market in the region. Germany, Italy, Russia, Poland, and France are major contributors to the European market for broaching machines. The European automotive industry, which boasts the largest passenger car fleet globally, significantly influences the region's market growth. Electromechanical broaching machines are popular choices in Europe due to their motor-driven and hydraulic systems. These machines utilize vertical or horizontal configurations, with draw heads or pulling heads, and a follower to shape metal pieces.

Furthermore, the market offers various types, including electromechanical broach machines, which provide high precision and efficiency. The market is driven by the automotive sector's growth and the increasing demand for high-precision metalworking. The industry's focus on reducing production costs and improving productivity further fuels the market's expansion.

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Market Driver

Increasing demand for CNC-incorporated machine tools is the key driver of the market. In the realm of manufacturing, particularly within metal industries, CNC broaching machines have emerged as indispensable tools for achieving high precision metal removal. These technologically advanced machines enable the production of intricate shapes and contours with minimal human intervention.

Furthermore, the bed of a CNC broaching machine holds a tool support adaptor, which facilitates the insertion of various cutting tools for the broaching procedure. High-volume manufacturers rely on CNC broaching machines to maintain efficiency and productivity, as they eliminate the need for manual estimation of pressure during the metal cutting process. These machines are not only technologically advanced but also offer the flexibility to produce large quantities of parts with consistent accuracy. The market for CNC broaching machines is thriving, with numerous key players offering both new and secondhand machines.

Market Trends

Integration of automation solution providers with broaching machine companies is the upcoming trend in the market. In the industrial machinery manufacturing sector, broaching machines have gained significant attention due to their ability to fabricate complex shapes and contours in various industries, such as aerospace and defense, oil and gas, and automotive. Two main types of broaching machines are Vertical Broaching Machines and Horizontal Broaching Machines.

Further, to stay competitive and meet the increasing demand for automation, companies are integrating advanced technologies like Computer Numerical Control (CNC), Servo technology, and Software technology into their machines. For instance, Cabe Stozzatrici's Manaca table-up broaching machines utilize FANUC control panels for enhanced automation. Energy efficiency and optimal end results are crucial in today's market, and companies are responding by developing strong and efficient control systems. These systems not only save power but also ensure precise and accurate broaching processes. As the market continues to evolve, it is essential for companies to stay ahead of the curve by offering innovative and efficient solutions to meet the demands of their customers.

Market Challenge

Increasing price competition due to volatile input cost is a key challenge affecting market growth. In the manufacturing sector, broaching machines play a crucial role in surface finishing for various industries, including automotive and heavy industrial instruments. The industrial machinery sector relies heavily on these machines for precision finishing. The primary raw materials used in the production of broaching machines are stainless steel, iron, bronze, and copper. Fluctuations in the prices of these materials can significantly impact the cost of manufacturing broaching machines. To mitigate the effects of raw material price instability, many leading companies in the market have established long-term contracts with their suppliers. These contracts help to maintain a steady supply of raw materials and reduce the impact of price fluctuations on their businesses.

However, smaller firms may not have the same level of purchasing power and are more susceptible to price fluctuations. The manufacturing process of broaching machines primarily involves welding and fabrication from a steel mono-block. Consequently, any variation in the price of steel directly affects the cost of producing broaching machines. CAD systems and CNC technology are essential tools in the production process, ensuring precision and efficiency. The broaching machine market is competitive, with several key players dominating the landscape.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

American Broach and Machine Co. - The company offers broaching machines such as table top SP broaching machines, vertical table-up broaching machines, and twin cylinder pull-down broaching machines.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Accu Cut Diamond Tool Co.

- American Broach and Machine Co.

- Andy Machine Tools

- Apex Broaching Systems Inc.

- Arthur Klink GmbH

- Axisco Precision Machinery Co. Ltd.

- Broaching Machine Specialties

- Colonial Tool Group Inc.

- ekin S. Coop.

- Forest Technology GmbH and Co. KG

- General Broach Co.

- Hoffmann Group

- Miller Broach

- Mitsubishi Heavy Industries Ltd.

- NACHI FUJIKOSHI Corp.

- Phoenix Inc.

- Pioneer Broach Co.

- Stenhoj Hydraulik AS

- Sunny Enterprises Co. Ltd.

- The Ohio Broach and Machine Co.

- Ty Miles Inc.

- V W Broaching Service Inc.

- YEOSHE HYDRAULICS CO. LTD.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The broaching machine market encompasses the production and sale of vertical and horizontal broaching machines used in various industries for metal cutting and surface finishing applications. These machines are integral to the fabrication process in industrial machinery manufacturing, particularly in sectors like aerospace and defense, oil and gas, and automotive. Advanced technologies such as automation, computer numerical control (CNC), servo technology, and software technology are increasingly being integrated into broaching machines for high precision and power savings. Broaching machines are used for metal removal in the production of fabricated metal products, heavy industrial equipment, and components such as gears, transmission shafts, steering wheel hubs, and steering yokes.

Furthermore, they are also employed in the manufacturing of internal gear cutting, internal helical broaching, and electromechanical broach machines. The market caters to both high-volume manufacturers and small-scale firms, offering technologically advanced machines as well as secondhand options. Motors, hydraulic drives, rams, draw heads, pulling heads, followers, beds, tool support adaptors, and other components are essential parts of broaching machines. The market is driven by the increasing demand for high-precision broaching procedures in various industries, including automotive and industrial machinery sectors. The integration of CAD systems and CNC controls further enhances the capabilities of these machines, making them indispensable tools for metal industries.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

142 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.5% |

|

Market Growth 2024-2028 |

USD 109.1 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.24 |

|

Regional analysis |

Europe, APAC, North America, South America, and Middle East and Africa |

|

Performing market contribution |

APAC at 38% |

|

Key countries |

China, Germany, US, UK, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

Accu Cut Diamond Tool Co., American Broach and Machine Co., Andy Machine Tools, Apex Broaching Systems Inc., Arthur Klink GmbH, Axisco Precision Machinery Co. Ltd., Broaching Machine Specialties, Colonial Tool Group Inc., ekin S. Coop., Forest Technology GmbH and Co. KG, General Broach Co., Hoffmann Group, Miller Broach, Mitsubishi Heavy Industries Ltd., NACHI FUJIKOSHI Corp., Phoenix Inc., Pioneer Broach Co., Stenhoj Hydraulik AS, Sunny Enterprises Co. Ltd., The Ohio Broach and Machine Co., Ty Miles Inc., V W Broaching Service Inc., and YEOSHE HYDRAULICS CO. LTD. |

|

Market dynamics |

Parent market analysis, market growth inducers and obstacles, market forecast, fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, market condition analysis for the forecast period |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across Europe, APAC, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch