Bottling Line Machinery Market Size 2024-2028

The bottling line machinery market size is forecast to increase by USD 1.1 billion at a CAGR of 4.36% between 2023 and 2028.

- The market is witnessing significant growth due to several key trends. An increase in demand for digitally printed packaging is the key driver of the bottling line machinery market, as brands seek more personalized and visually appealing packaging solutions. The upcoming trend is innovations in bottling line machinery, with advancements in automation, precision, and speed. These innovations are enhancing production efficiency, reducing waste, and improving product quality, enabling manufacturers to meet the growing demands of the packaging industry.

- Additionally, innovations in bottling line machinery continue to shape the market, with advancements in automation, robotics, and data analytics enhancing production efficiency and reducing costs. However, the influence of Small and Medium Enterprises (SMEs) In the bottling industry poses risks to market growth. SMEs often lack the resources to invest in advanced machinery, which could limit their competitiveness In the market. Overall, the market is poised for strong growth, with these trends and challenges shaping its trajectory.

What will be the Size of the Bottling Line Machinery Market During the Forecast Period?

- The market encompasses the production and sale of machinery used in the manufacturing process of various beverage products, including healthy beverages, wine, soft drinks, and even medicines, cleaning supplies, and pet packaging. This market is driven by the increasing demand for automated technology in beverage manufacturing plants to enhance efficiency and productivity. The semi-automatic segment holds a significant market share due to its cost-effectiveness, while the automatic segment is expected to grow at a strong rate due to its ability to handle large volumes and ensure precision filling mechanisms and automated capping systems. The market trends include the adoption of single-serve packaging and bottle-cleaning technologies for improved hygiene and consumer convenience. Additionally, the increasing focus on quality control sensors to ensure product consistency and safety is a key trend shaping the market dynamics.

How is this Bottling Line Machinery Industry segmented and which is the largest segment?

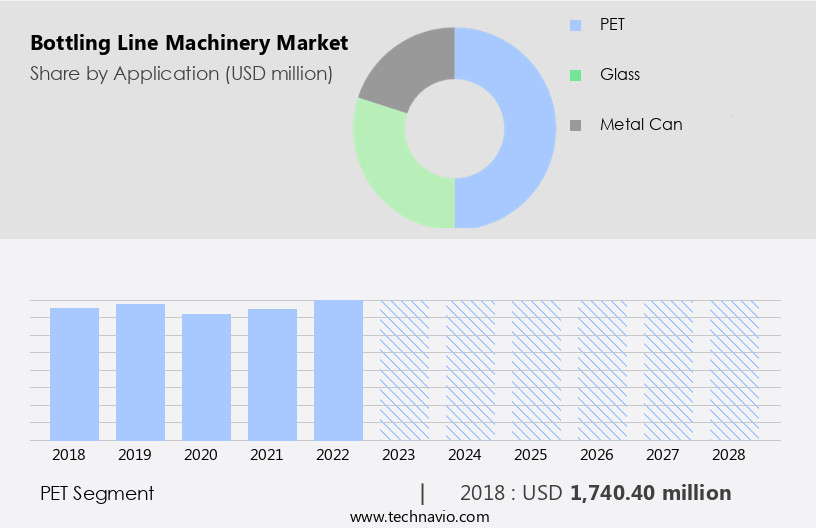

The bottling line machinery industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- PET

- Glass

- Metal can

- Technology

- Automatic

- Semi-automatic

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- UK

- North America

- US

- South America

- Middle East and Africa

- APAC

By Application Insights

The PET segment is estimated to witness significant growth during the forecast period. The PET market is experiencing significant growth due to the increasing preference for PET packaging In the beverage industry. PET's ease of molding makes it an ideal choice for bottling various beverage types, including healthy drinks, sports drinks, low-calorie drinks, nutritional drinks, and private label brands. Contract manufacturing and automation technology have further fueled the demand for bottling line machinery, enabling the production of processed food products, cosmetics, personal care, medicines, and cleaning supplies. The market is segmented into the beverages segment, which includes wine, soft drinks, and alcoholic products, and the chemicals segment, which includes organic and inorganic solvents, acids, and viscosities.

The geriatric population and disease incidences have also contributed to the market's growth. However, sustainability concerns and stringent regulations pose challenges to the market's expansion. The market incorporates manufacturing machines, filling, capping, labeling, precision filling mechanisms, automated capping systems, quality control sensors, sanitation measures, and touchless technologies. Digitalization, data analytics, and Industry 4.0 trends are transforming the market, with smart manufacturing techniques, hygienic design features, and retraining programs ensuring optimal efficiency.

Get a glance at the share of various segments. Request Free Sample

The PET segment was valued at USD 1.74 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 35% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The market in Asia Pacific is projected to experience significant growth due to the region's large consumer base and increasing investments in beverage manufacturing. With a population exceeding 4.5 billion, APAC is home to numerous beverage industries, including soft drink manufacturers, juice producers, and bottled water companies. The economic growth in this region, driven by a growing middle class and increasing purchasing power, has fueled the expansion of these industries. The adoption of automatic technology in bottling line machinery is a key trend, with semi-automatic and fully automatic systems gaining popularity. The beverage segment, which includes healthy beverages, sports drinks, low-calorie drinks, nutritional drinks, and functional beverages, is a major driver of market growth.

Additionally, the production of processed food products, chemicals, medicines, cleaning supplies, and other industries also contributes to the demand for bottling line machinery. The market is further influenced by the increasing consumption of beverages, particularly ready-to-drink beverages, and the shift towards lightweight packaging and sustainable materials. Industrial automation, digitalization, and data analytics are also key trends In the market, with smart manufacturing techniques and hygienic design features becoming increasingly important. Government support through incentives and industrial automation initiatives, such as PLCs, SIG, and Liquibox, also contribute to market growth.

Market Dynamics

Our bottling line machinery market researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Bottling Line Machinery Industry?

An increase in demand for digitally printed packaging is the key driver of the market.

- The market is witnessing significant growth due to the increasing demand for beverage products, including healthy beverages, In the US and globally. Contract manufacturing has become a popular trend In the beverage industry, leading to an increase In the demand for automatic technology in beverage manufacturing plants. The Beverages segment, which includes sports drinks, low-calorie drinks, nutritional drinks, and functional beverages, is expected to dominate the market. The market also caters to the needs of chemical manufacturing plants, handling flammable and inflammable liquids, organic and inorganic solvents, and various acidities and viscosities. The Alcoholic products segment, including wine and medicines, also contributes to the market growth. The geriatric population and rising disease incidences have led to an increase In the demand for bottled water and other healthy beverages. Manufacturing machines used for liquids, including beverages, require precision filling mechanisms, automated capping systems, quality control sensors, and sanitation measures. Touchless technologies and digital twin technology are being adopted to ensure hygienic design features and smart manufacturing techniques.

- Further, the trend toward sustainable materials, such as PET, glass, metal cans, aluminum, and steel, is also driving the market. Digitalization, data analytics, and Industry 4.0 technologies, including sensors, real-time monitoring, and robotics, are being integrated into the bottling line machinery to increase efficiency and productivity. Smart manufacturing techniques and flexible production lines are enabling brands to offer customized and personalized packaging solutions, such as single-serve packaging and prepared food, cosmetics, personal care, and chemicals. The market is expected to continue growing, driven by increasing beverage consumption, lightweight packaging, and government support through incentives and industrial automation initiatives, including PLCs, SIG, Aseptic carton packaging, bag-in-box filling, Liquibox, Syntegon, Bayer, and other key players.

What are the market trends shaping the Bottling Line Machinery Industry?

Innovations in bottling line machinery are the upcoming market trend.

- The market is witnessing significant growth due to the increasing production of beverage products, including healthy beverages, sports drinks, low-calorie drinks, nutritional drinks, and prepared food products. Contract manufacturing and automation technology are key drivers in this market, with semi-automatic and automatic technology dominating the beverages segment. The market caters to various industries, such as chemical manufacturing plants, wine, soft drink manufacturers, medicines, cleaning supplies, and cosmetics. Beverage consumption trends, such as the geriatric population and disease incidences, necessitate the use of manufacturing machines for liquids, including alcoholic products. The market offers solutions for handling flammable and inflammable liquids, organic and inorganic solvents, acidities, and viscosities. Beverage manufacturing plants use various packaging types, such as PET, single-serve packaging, and aseptic carton packaging, to meet consumer demands for lightweight and sustainable materials.

- Moreover, the market also focuses on smart manufacturing techniques, hygienic design features, and retraining programs for routine maintenance tasks. Industrial automation technologies, such as Programmable Logic Controllers (PLCs), SIG, and Liquibox, are employed to ensure precision filling mechanisms, automated capping systems, quality control sensors, and sanitation measures. Touchless technologies, digital twin technology, simulation, and automation technologies, including robotics and artificial intelligence, are integral to Industry 4.0. Sustainability is a critical factor In the market, with a focus on PET, glass, metal, aluminum, and steel bottles. Smart manufacturing techniques and the use of sensors enable real-time monitoring and digitalization, ensuring the production of functional beverages, ready-to-drink beverages, and other liquid products. Government support, incentives, and the integration of cleaning supplies and labeling systems further enhance the market's growth.

What challenges does the Bottling Line Machinery Industry face during its growth?

The influence of SMEs in the bottling industry leading to risks is a key challenge affecting the industry growth.

- The market is characterized by intense competition due to the presence of numerous small and medium-sized enterprises (SMEs). Manufacturers of bottling line machinery face challenges in meeting customer demands for affordable solutions while maintaining quality standards. Large companies often opt for fixed-price contracts, which can result in additional costs for machinery companies. However, market players are also confronted with the volatility of raw material prices, particularly for aluminum and steel, which are essential for manufacturing bottling line machinery. These economic and geopolitical factors pose significant cost challenges for the industry. Moreover, the increasing preference for healthy beverages, such as sports drinks, low-calorie drinks, nutritional drinks, and functional beverages, is driving the demand for advanced bottling line machinery. The semi-automatic and automatic technology segments are witnessing significant growth In the beverages segment, including processed food products and prepared food. Additionally, the cosmetics and personal care industries are adopting bottling line machinery for their liquid products. The market is also witnessing the adoption of digitalization, data analytics, and Industry 4.0 technologies, including sensors, real-time monitoring, and automation technologies, such as robotics and artificial intelligence.

- These advancements enable smart manufacturing techniques, hygienic design features, and sustainable materials, such as PET, glass, and metal cans. Furthermore, the trend towards single-serve packaging, flexible production lines, and smart features, such as digital twin technology and simulation, is gaining momentum. The government's support through incentives and industrial automation initiatives, such as Programmable Logic Controllers (PLCs), SIG, Aseptic carton packaging, bag-in-box filling, Liquibox, Syntegon, Bayer, and other leading machinery manufacturers, are also contributing to the market's growth. The market is expected to continue its expansion, driven by the increasing consumption of beverages, including wine, soft drinks, juices, bottled water, and alcoholic products, particularly among the geriatric population and those with disease incidences. In summary, the market is experiencing significant growth due to the increasing demand for healthy beverages, advanced technology, and sustainable materials. Market players are addressing challenges related to raw material costs and customer demands while adopting digitalization, data analytics, and Industry 4.0 technologies to remain competitive. The market is expected to continue its expansion, driven by the increasing consumption of beverages and the growing trend towards smart manufacturing techniques and sustainable materials.

Exclusive Customer Landscape

The bottling line machinery market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the bottling line machinery market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, bottling line machinery market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry. The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Adelphi Holdings Ltd. Inc.

- ATS Automation Tooling Systems Inc.

- Barry Wehmiller Group Inc.

- Coesia SpA

- Della Toffola Spa

- EDL Packaging Engineers Inc.

- GEA Group AG

- Mpac Group Plc

- PallayPack Inc.

- Pro Mach Inc.

- Salzgitter AG

- Syntegon Technology GmbH

- Tetra Laval SA

- Uhlmann Pac Systeme GmbH and Co. KGA

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a range of automated systems designed to fill, cap, label, and package various liquid products. These machines play a crucial role In the production process of beverages, including healthy beverages, sports drinks, low-calorie drinks, nutritional drinks, and private label brands. The market exhibits significant growth due to the increasing demand for automated technology In the manufacturing sector. Contract manufacturing plants, particularly those producing beverages, heavily rely on these machines to maintain efficiency and productivity. The semi-automatic segment holds a substantial market share due to its cost-effectiveness and ease of use. However, the beverages segment, which includes wine, soft drinks, and bottled water, dominates the market in terms of revenue. Bottling line machinery caters to various industries, such as chemical manufacturing plants, food and beverage manufacturing plants, and cosmetics and personal care. The machines are designed to handle a wide range of liquids, including flammable and inflammable liquids, organic and inorganic solvents, and acidities and viscosities of varying degrees. The market is witnessing a shift towards sustainable materials and lightweight packaging. This trend is driven by the growing awareness of environmental concerns and the need for cost-effective solutions.

Flexible production lines and functional beverages are also gaining popularity, requiring machinery that can adapt to changing product requirements. Digitalization and data analytics are transforming the market. Digital twin technology, simulation, and real-time monitoring enable predictive maintenance and optimization of production processes. Automation technologies, such as robotics, artificial intelligence, and industrial automation, are being integrated into bottling lines to enhance efficiency and improve product quality. Sustainability is a key consideration In the design and manufacturing of bottling line machinery. Smart manufacturing techniques and hygienic design features are becoming increasingly important to meet the evolving needs of consumers and regulatory bodies. Retraining programs and routine maintenance tasks ensure that these machines remain operational and effective. The market is subject to various market dynamics, including technological advancements, changing consumer preferences, and government incentives. The industry is also influenced by trends such as Industry 4.0, which focuses on interconnectivity and data-driven decision-making. In conclusion, the market is a dynamic and evolving industry that plays a vital role In the production of various liquid products. The market is driven by factors such as automation, digitalization, sustainability, and changing consumer preferences. Companies operating in this market must stay abreast of these trends to remain competitive and meet the demands of their customers.

|

Bottling Line Machinery Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

165 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.36% |

|

Market growth 2024-2028 |

USD 1.1 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.11 |

|

Key countries |

China, US, Germany, UK, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Bottling Line Machinery Market Research and Growth Report?

- CAGR of the Bottling Line Machinery industry during the forecast period

- Detailed information on factors that will drive the Bottling Line Machinery growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the bottling line machinery market growth of industry companies

We can help! Our analysts can customize this bottling line machinery market research report to meet your requirements.