Dairy Processing Equipment Market Size 2024-2028

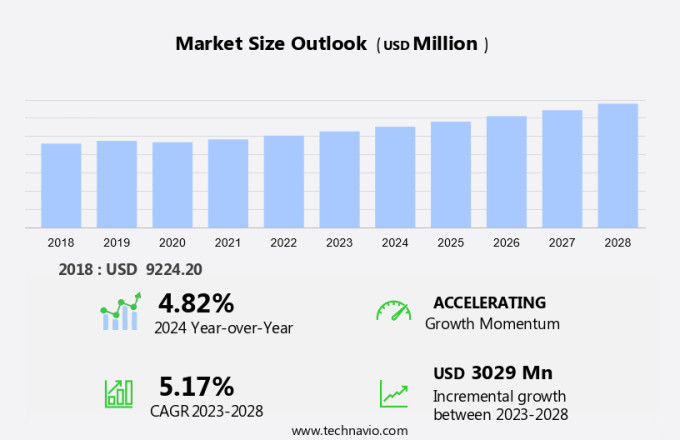

The dairy processing equipment market size is forecast to increase by USD 3.03 billion at a CAGR of 5.17% between 2023 and 2028.

- The market is witnessing significant growth due to several key trends. The increasing demand for fortified dairy products, driven by consumer health consciousness, is a major growth factor. Another trend is the rising adoption of High Pressure Processing (HPP) technology, which ensures the preservation of nutritional value and extends the shelf life of dairy products. Homogenizers, membrane filters, separators, mixing & blenders, evaporators & dryers, pasteurizers, and other specialized equipment play crucial roles in ensuring the efficiency of production and the quality of milk-based products. Additionally, the increasing preference for dairy-free alternatives, such as plant-based milk and yogurt, is propelling market growth. These trends are shaping the future of the market and presenting new opportunities for market participants.

What will be the Size of the Dairy Processing Equipment Market During the Forecast Period?

- The market is experiencing significant growth due to increasing demand for automated process solutions and technology advancements In the production of processed milk products. Homogenizers, membrane filters, separators, mixing & blenders, evaporators & dryers, pasteurizers, and other specialized equipment play crucial roles in ensuring the efficiency of production and the quality of milk-based products.

- Moreover, the integration of robotics in milking systems and cold chain facilities has further streamlined operations and reduced operational expenses. New product development, portfolio expansion, and innovation continue to drive market growth, with a focus on protein concentrates, whey-based supplements, fortified dairy products, and applications in infant nutrition and geriatric nutrition formulae. Advancements in technology are enabling the production of high-quality, safe, and sustainable dairy products, making this market an attractive investment opportunity for manufacturers and suppliers.

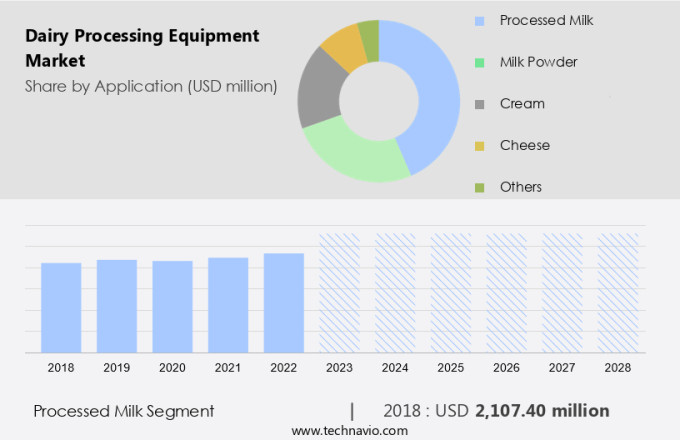

How is this Dairy Processing Equipment Industry segmented and which is the largest segment?

The dairy processing equipment industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Processed milk

- Milk powder

- Cream

- Cheese

- Others

- Type

- Pasteurizers

- Homogenizers

- Separators

- Evaporators and dryers

- Others

- Geography

- APAC

- China

- India

- Europe

- Germany

- France

- North America

- US

- South America

- Middle East and Africa

- APAC

By Application Insights

- The processed milk segment is estimated to witness significant growth during the forecast period.

Processed milk is produced through heat treatment of raw milk, utilizing pasteurization and UHT processing. Pasteurization eliminates bacteria, while UHT processing eradicates milk spores, ensuring extended shelf life. Equipment such as pasteurizers, homogenizers, and heat exchangers are integral to milk processing. Market leaders are innovating advanced technologies, including HTST heating, which heats milk above 161°F for over 15 seconds, enhancing nutritional benefits and boosting demand. Additionally, the dairy industry focuses on cold chain facilities, automation, and digital-based livestock management for improved efficiency and reduced energy wastage. The market expands to cater to various sectors, including food service, fast-food outlets, and baby food production, driven by changing lifestyles and the rise in geriatric and infant populations.

Get a glance at the Dairy Processing Equipment Industry report of share of various segments Request Free Sample

The processed milk segment was valued at USD 2.11 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

- APAC is estimated to contribute 37% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The Asia Pacific (APAC) region is a significant market for dairy processing equipment due to the high volume of milk production and processing in countries like Australia, India, and China. The prevalence of bone diseases, particularly among females, is a major driver for the demand for dairy products in this region. According to The World Bank Group, females accounted for nearly half of the population in China, Japan, India, and Australia in 2022. As a result, the increasing likelihood of bone-related diseases among this demographic is fueling the growth of the market in APAC. This trend is expected to continue during the forecast period, driven by the rising consumption of dairy products such as cheese, butter, and milk powder, as well as the increasing popularity of fortified dairy products and infant formulas.

Market Dynamics

Our dairy processing equipment market researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Dairy Processing Equipment Industry?

Growing market for fortified dairy products is the key driver of the market.

- The market encompasses a range of technologies and machinery used to produce various dairy products, including baby foods, cheese, butter, creams, and milk. With changing lifestyles and increasing health consciousness, there is a growing demand for high-quality, fortified dairy products. These products are often fortified with essential nutrients such as calcium, protein, vitamins, and minerals through processes like bacterial fermentation, dehydration, evaporation, filtration, and homogenization. Automation processes, such as digital-based livestock management and robotic milking, are increasingly being adopted to improve efficiency and reduce operational expenses. The market is also witnessing a trend towards eco-friendly packaging and sustainable practices, as well as new product development in areas like protein concentrates and nanofiltration.

- Moreover, dairy processing equipment includes pasteurizers, homogenizers, separators, and evaporators & dryers. These machines ensure the production of high-quality dairy products, such as processed milk, cheese, and yogurt. Cold chain facilities are essential for maintaining the temperature of dairy products during storage and transportation, ensuring food safety and product integrity. The dairy processing industry is also catering to the needs of the food service sectors, including fast-food outlets, and the growing demand for infant formulas and geriatric nutrition formulae. The market is expected to continue growing due to the increasing consumption of dairy products, particularly cheese, and the rising birth rate, which leads to an increase in demand for infant nutrition.

What are the market trends shaping the Dairy Processing Equipment Industry?

Increasing adoption of HPP technology is the upcoming market trend.

- The market is experiencing significant growth due to the increasing adoption of automation processes In the dairy industry. This trend is driven by changing lifestyles and the rising demand for high-quality dairy products, including baby foods, cheese, butter, creams, and liquid milk. The bacterial fermentation process, used In the production of yogurt and other fermented dairy products, is also gaining popularity. Advancements in technology have led to the development of eco-friendly packaging solutions and digital-based livestock management systems, reducing operational expenses and promoting sustainability. The efficiency of equipment, such as homogenizers, separators, filtration systems, and evaporators & dryers, is crucial in minimizing energy wastage and increasing productivity.

- Moreover, the demand for fortified dairy products, including calcium, vitamins B6 and B12, riboflavin, and proteins, is increasing, particularly In the food service sectors and fast-food outlets. Membrane filtration equipment, including nanofiltration and ultrafiltration, is used to dehydrate milk powder and produce protein concentrates, which are essential In the production of these fortified dairy products. The market is also witnessing new product development, with a focus on portfolio expansion and the production of quality milk-based products. The use of membrane technology, such as microfiltration and reverse osmosis, is becoming increasingly common In the dairy industry to ensure high food quality and minimize contamination.

What challenges does the Dairy Processing Equipment Industry face during its growth?

Increasing consumer preference for dairy-free alternatives is a key challenge affecting the industry growth.

- The market is experiencing significant growth due to various factors. One key driver is the changing lifestyles and consumer preferences for high-quality dairy products, such as cheese, butter, and milk. Automation processes, including homogenization, pasteurization, and separations using equipment like homogenizers, pasteurizers, and separators, have become essential for increasing efficiency and reducing operational expenses. Moreover, advancements in technology, such as membrane filtration equipment using membrane technology for ultrafiltration, nanofiltration, and reverse osmosis, have improved the production of dairy products, including calcium-rich milk, protein concentrates, and fortified dairy products. The baby food industry also relies heavily on dairy processing equipment for the production of infant formulas and cereals.

- Additionally, the demand for eco-friendly packaging and sustainable practices has led to the development of reusable packaging and energy-efficient cold chain facilities. The food service sectors, including fast-food outlets, and the baby food industry also require cold chain facilities to maintain the quality and safety of dairy products. Furthermore, the increasing birth rate and the growing geriatric population have resulted in a higher demand for nutritional supplements, such as protein-rich supplements and vitamin-fortified dairy products. Cheese consumption is also on the rise, leading to an increase in cheese processing equipment demand. Therefore, the market is expected to continue its growth trajectory due to the increasing demand for high-quality dairy products, advancements in technology, and changing consumer preferences.

Exclusive Customer Landscape

The dairy processing equipment market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the dairy processing equipment market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, dairy processing equipment market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABL Technology Ltd.

- Admix Inc.

- Agrometal Ltd.

- Alfa Laval AB

- Feldmeier Equipment Inc.

- GEA Group AG

- Goma Engineering Pvt. Ltd.

- Hillenbrand Inc.

- IDMC Ltd.

- IMA Industria Macchine Automatiche Spa

- John Bean Technologies Corp.

- Krones AG

- Nordic Dairy Technology ApS

- Paul Mueller Co. Inc.

- Proxes GmbH

- Sanchelima International Inc.

- Scherjon Equipment Holland BV

- SPX FLOW Inc.

- SSP Pvt. Ltd.

- Tetra Laval SA

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The dairy processing industry continues to evolve, driven by various market dynamics that shape the demand for advanced equipment and technologies. One significant trend is the automation process in dairy farming and processing, which enhances efficiency and reduces operational expenses. This automation extends to digital-based livestock management and robotic milking, ensuring high food quality and eco-friendly practices. The increasing awareness of health and wellness has led to an increase in demand for fortified dairy products, such as those enriched with essential minerals like calcium and vitamins like riboflavin and vitamin B12. This has resulted in new product development, with a focus on creating quality milk-based products that cater to changing lifestyles.

Furthermore, the market is witnessing significant growth due to the need for efficient and sustainable processing methods. Membrane filtration equipment, including nanofiltration and reverse osmosis systems, is gaining popularity for their ability to remove impurities and enhance product quality. These systems also minimize energy wastage and contribute to the overall sustainability of the industry. Moreover, the food service sectors and fast-food outlets are major consumers of dairy products, driving the demand for specialized equipment like homogenizers and pasteurizers. These pieces of equipment ensure the consistent quality and texture of dairy products, making them suitable for commercial applications. The demand for eco-friendly packaging solutions is another key trend shaping the dairy processing industry.

Moreover, reusable packaging and sustainable materials are becoming increasingly popular, as consumers become more conscious of their environmental impact. This trend is expected to continue, with companies investing in portfolio expansion to cater to this growing demand. The dairy processing industry also faces challenges related to the efficiency of equipment and the need for minimal energy wastage. Evaporators and dryers, for instance, are essential for producing milk powder and other dairy products. However, they consume significant amounts of energy, making energy efficiency a critical consideration for manufacturers. Innovations in membrane technology, such as microfiltration and ultrafiltration, are helping to address these challenges by improving the efficiency of equipment and reducing energy consumption.

In addition, these technologies also enable the production of high-quality dairy products with minimal processing time, making them a popular choice for manufacturers. The dairy processing industry is also witnessing a shift towards sustainable and ethical practices. This includes the use of eco-friendly packaging, as well as the adoption of ethical farming practices. Companies are investing in sustainable milk farms and implementing ethical labor practices to meet the growing demand for ethically produced dairy products. Therefore, the dairy processing industry is undergoing significant changes, driven by trends such as automation, health and wellness, sustainability, and efficiency. These trends are shaping the demand for advanced equipment and technologies, with a focus on eco-friendly practices and minimal energy wastage. Companies that can adapt to these trends and invest in sustainable and efficient processing methods are well-positioned to succeed in this dynamic market.

|

Dairy Processing Equipment Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

183 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.17% |

|

Market growth 2024-2028 |

USD 3.03 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.82 |

|

Key countries |

US, China, Germany, India, and France |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Dairy Processing Equipment Market Research and Growth Report?

- CAGR of the Dairy Processing Equipment industry during the forecast period

- Detailed information on factors that will drive the Dairy Processing Equipment growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the dairy processing equipment market growth of industry companies

We can help! Our analysts can customize this dairy processing equipment market research report to meet your requirements.