Extrusion Coatings Market Size 2024-2028

The extrusion coatings market size is forecast to increase by USD 1.3 billion at a CAGR of 4.5% between 2023 and 2028.

- The market is experiencing significant growth due to increasing demand from the packaging and automotive sectors. Dairy and non-dairy products are major applications driving market expansion, with a focus on improving product shelf life and enhancing visual appeal through coatings. Carbon footprint reduction is a key trend, leading to the adoption of bio-based polymers. Design flexibility, printability, sustainability, temperature resistance, abrasion resistance, and grease resistance are essential features sought after by end-users. In the US, infrastructure investment in the construction sector is expected to boost demand for extrusion coatings, particularly in the form of LDPE films. Fluctuating raw material costs remain a challenge, necessitating continuous price negotiations and cost optimization strategies. In summary, the market is thriving due to its versatility in various industries and the demand for sustainable, high-performance coatings.

What will be the Size of the Market During the Forecast Period?

- The market encompasses a range of materials and applications within the packaging sector. This market utilizes various polymers, including polyethylene (PE), ethylene vinyl acetate (EVA), ethylene butyl acrylate (EBA), polypropylene (PP), and polyethylene terephthalate (PET), for the production of extrusion coatings. PE, a versatile plastic, is widely used due to its excellent moisture barrier properties and sealability. In the material segment, LDPE (low-density polyethylene) is a popular choice due to its flexibility and clarity. Extrusion coatings find extensive applications in various industries. In the packaging sector, they are used for coating paperboard and cardboard, polymer films, metal foils, and liquid packaging.

- Moreover, flexible packaging is a significant application area, as these coatings enhance the weather ability, gloss, finish, and barrier properties of the packaging materials. Beyond packaging, extrusion coatings are used as protective and decorative coverings in the automotive, building and construction, medical and pharmaceutical, and paper and paperboard industries. The substrate, which can be paper, plastic, or metal, is coated with the polymer to improve its surface properties. Extrusion coatings are essential for enhancing the protective qualities of various materials. For instance, in the automotive industry, these coatings are used to improve the weather resistance of car parts. In building and construction, they are used for moisture barrier protection and to enhance the durability of roofing materials.

How is this market segmented and which is the largest segment?

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Material

- Polyethylene

- Ethylene Vinyl Acetate

- Ethylene Butyl Acrylate

- Others

- Geography

- APAC

- China

- India

- Europe

- Germany

- France

- North America

- US

- Middle East and Africa

- South America

- APAC

By Material Insights

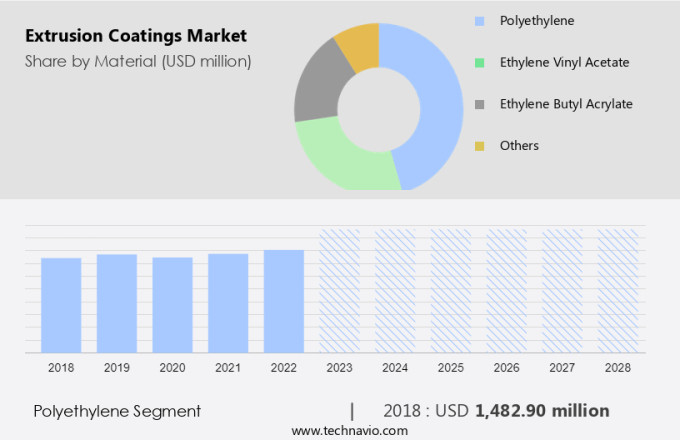

- The polyethylene segment is estimated to witness significant growth during the forecast period.

Polyethylene, a popular plastic type among consumers, is widely used due to its thermoplastic properties, enabling it to be melted and solidified repeatedly. Low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), high-density polyethylene (HDPE), and ultrahigh molecular weight polyethylene (UHWMPE) are various polyethylene materials applied in extrusion coating. This plastic's durability is a significant advantage, as it is resistant to fading, chipping, and various chemicals, including acids and caustic solutions. Extrusion coatings, primarily made from polyethylene, are increasingly utilized in various industries due to their design flexibility and printability. In the packaging sector, these coatings enhance the sustainability of dairy and non-dairy products by extending their shelf life and reducing carbon footprint.

Get a glance at the market report of share of various segments Request Free Sample

The polyethylene segment was valued at USD 1.48 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

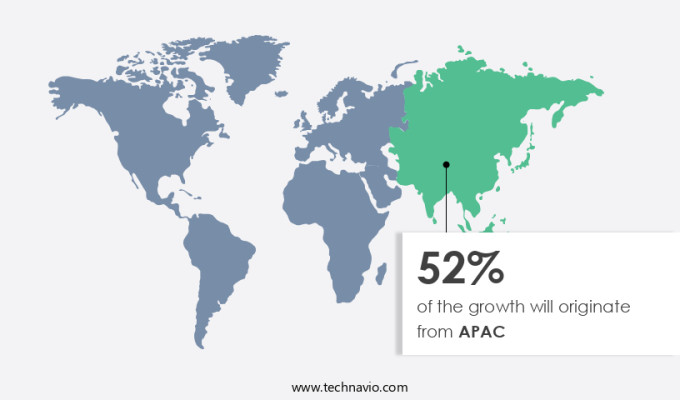

- APAC is estimated to contribute 52% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The market in APAC holds a significant share due to the region's strong economic expansion and population growth. This economic growth is driving demand for extrusion coating materials from various industries, including automotive, construction, packaging, and medical devices. One of the primary reasons for the market's growth in APAC is the increasing use of LDPE (Low-Density Polyethylene) packaging in the food and beverage sector. In countries such as China, India, Japan, South Korea, and Indonesia, the demand for extrusion coatings in food and beverage packaging is on the rise. These coatings provide a decorative and protective covering to the surface, enhancing the product's weather ability, gloss, finish, and clarity.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in adoption of Extrusion Coatings Market?

Increasing demand from packaging industry is the key driver of the market.

- The market holds substantial significance in various industries due to the unique properties offered by this coating technology. One major application sector is in the production of transport-specific packaging, particularly for liquids. This type of packaging is essential for various industries such as food, chemicals, pharmaceuticals, and construction. For instance, in the food industry, bakery goods, dairy products, frozen foods, meat and poultry, confectionery, and cookies are commonly packaged using flexible packaging. The benefits of this packaging include cost savings, consumer convenience, extended shelf life, and environmental sustainability. In the context of liquid food packaging, essential attributes include design flexibility, printability, aesthetics, and sustainability.

- Moreover, extrusion coatings provide additional benefits such as temperature resistance, abrasion resistance, grease resistance, lower coefficient of friction, and slower rate of water vapor transfer. These features are crucial in harsh working environments where the packaging may be exposed to high temperatures, pressure, and harmful chemicals. Moreover, extrusion coatings are extensively used in other industries like photographic imaging, envelopes, medical, decorative arts, and construction. In the medical sector, for example, extrusion coatings are used to produce sterile and barrier packaging for medical devices and pharmaceuticals. In the photographic industry, they are used to produce films and photographic paper. In the decorative arts, they are used to create laminated materials for various applications.

What are the market trends shaping the Extrusion Coatings Market?

Rising demand from automotive sector is the upcoming trend in the market.

- Extrusion coatings play a significant role in various industries, particularly in the automotive sector. These coatings provide advantages such as enhanced acoustics, durability, strength, and weight reduction. In the automobile industry, extrusion coatings are utilized in various vehicle components. The global automotive industry is witnessing expansion as manufacturers aim to increase production worldwide. The popularity of passenger vehicles is on the rise due to their compact size, stylish designs, and economic value, making them an integral part of consumers' lifestyles. The burgeoning infrastructure development in several developing countries and the expansion of the automobile sector will fuel the growth of The market.

- Moreover, extrusion coatings find extensive applications in various industries, including the automotive sector. These coatings offer benefits such as improved acoustics, durability, strength, and weight reduction. In the automobile industry, extrusion coatings are utilized in various vehicle components. The global automotive industry is experiencing growth as manufacturers focus on increasing production globally. Passenger vehicles have gained immense popularity among consumers due to their compact size, stylish designs, and economic value, making them an essential component of people's lifestyles. The infrastructure development in numerous developing countries and the expansion of the automobile sector will drive the growth of The market during the forecast period.

What challenges does Extrusion Coatings Market face during the growth?

Fluctuating raw material costs is a key challenge affecting the market growth.

- The market is influenced by various factors, particularly in industries such as food and beverages, healthcare sectors, electronics, imaging, consumer goods, and polymer processing. The prices of raw materials used in manufacturing extrusion coating materials, including low-density polyethylene (LDPE) and ethylene-vinyl acetate (EVA), are subject to unpredictability due to their dependence on global crude oil prices. The increasing demand for polyethylene packaging in emerging economies and the volatile nature of petroleum-based raw materials pose challenges to the growth of the US the market. LDPE and HDPE, commonly used in packaging applications, are petroleum derivatives and thus, their prices are influenced by the prevailing prices of natural gas and crude oil.

- Furthermore, reconstruction activities in various sectors also contribute to the demand for extrusion coatings in the US market. Key players in this market include companies specializing in paperboard, aluminum foils, and corrugated fiberboards. The US the market is expected to witness steady growth due to the increasing demand for high-performance coatings in various industries.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast , partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Akzo Nobel NV

- Arkema Group.

- Borealis AG

- Chevron Phillips Chemical Co. LLC

- Davis Standard LLC

- Dow Chemical Co.

- DuPont de Nemours Inc.

- Eastman Chemical Co.

- Exxon Mobil Corp.

- Formosa Plastics Corp.

- Hanwha Corp.

- INEOS AG

- Lucobit AG

- LyondellBasell Industries N.V.

- NOVA Chemicals Corp.

- Qenos Pty Ltd.

- Reliance Industries Ltd.

- Repsol SA

- Saudi Basic Industries Corp.

- The Lubrizol Corp.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Extrusion coatings play a vital role in enhancing the performance and functionality of various substrates, including polyethylene, ethylene vinyl acetate, ethylene butyl acrylate, polypropylene, and polyethylene terephthalate. These coatings are applied to paperboard and cardboard, polymer films, metal foils, and other materials to improve their properties for diverse applications. In the packaging sector, extrusion coatings are used for liquid packaging, flexible packaging, medical packaging, and industrial packaging. They offer superior properties such as moisture barrier, sealability, and temperature resistance, making them suitable for dairy products, non-dairy products, and other food and beverages. Bio-based polymers are gaining popularity as extrusion coating materials due to their environment-friendly nature.

Moreover, the construction sector and infrastructure investment also utilize extrusion coatings for decorative covering and protective covering on various surfaces. Extrusion coatings offer design flexibility, printability, and sustainability, making them essential in various industries such as automotive, building and construction, medical and pharmaceutical, paper and paperboard, and electronics. They provide weather ability, gloss, finish, clarity, and barrier properties for liquids, gases, and vapors, ensuring a smooth surface with a low coefficient of friction and resistance to abrasion, chemicals, and adhesion. Extrusion coatings are also used in harsh working environments, including healthcare sectors, transportation-specific packaging, photographic imaging, envelopes, and construction. Their superior properties make them suitable for various applications, including harsh temperatures, pressure, and exposure to harmful chemicals.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

146 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.5% |

|

Market growth 2024-2028 |

USD 1.29 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.23 |

|

Key countries |

China, US, India, France, and Germany |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch