Industrial Gas Turbine Ignition System Market Size 2024-2028

The industrial gas turbine ignition system market size is forecast to increase by USD 2.13 billion at a CAGR of 10.03% between 2023 and 2028.

- The market is experiencing significant growth due to the increasing demand for cleaner sources of energy and energy education. Gas-fired turbines are becoming increasingly popular for eco-friendly energy generation, and waste heat recovery systems are being integrated to improve operational efficiencies. Additionally, the development of hybrid energy systems for gas turbines is gaining traction, allowing for more flexible energy generation. Furthermore, the fluctuation in gasoline prices is driving the need for more cost-effective energy solutions, making gas turbines an attractive option, especially as the integration of renewable energy sources continues to gain traction in the transition to more sustainable power generation. However, challenges such as the need for homogeneous stoichiometric operation at wide-open-throttle (WOT) and EGR tolerance at peak pressure levels must be addressed to ensure optimal performance. By focusing on these trends and challenges, market participants can position themselves for success in the evolving landscape.

What will be the Size of the Industrial Gas Turbine Ignition System Market During the Forecast Period?

- The market represents a significant segment in the broader electrical system market. These ignition systems are essential components of industrial gas turbines, facilitating the ignition of combustible fuels, such as natural gas and liquid fuels, in the combustion chambers. Ignition systems in industrial gas turbines employ various components, including igniters, exciters, and ignition leads, to generate high-output signals that initiate the spark discharge necessary for combustion. These systems play a crucial role in power generation, particularly in heavy-duty and light-duty gas turbines, as well as in microturbines. The ignition system's performance relies on the electrical system's efficiency and the ability to generate sufficient voltage for the igniter and spark plugs.

- The igniter produces a high-energy spark, which ignites the fuel in the combustion chamber. The exciter, in turn, generates the high voltage required by the igniter. The ignition leads transfer the electrical energy from the ignition system to the igniter and spark plugs. In the context of industrial gas turbines, ignition system components are designed to withstand harsh operating conditions, including high temperatures and mechanical stress. These systems are critical for continuous combustion engines, converting mechanical energy from the gas turbine into electrical energy. The market is driven by the increasing demand for electrical energy and the growing adoption of these turbines for power generation.

How is this Industrial Gas Turbine Ignition System Industry segmented and which is the largest segment?

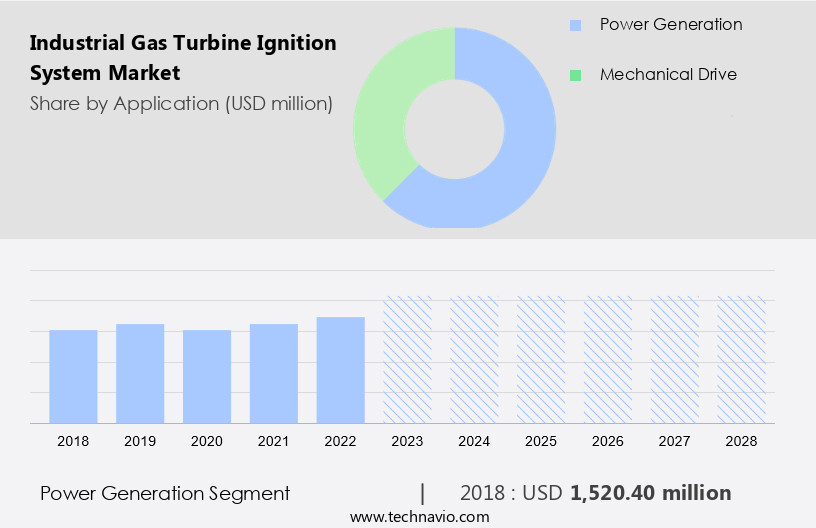

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Power generation

- Mechanical drive

- Geography

- APAC

- China

- India

- North America

- US

- Europe

- Germany

- Middle East and Africa

- South America

- Brazil

- APAC

By Application Insights

- The power generation segment is estimated to witness significant growth during the forecast period. Industrial gas turbine ignition systems play a crucial role In the power generation industry, particularly in the operation of industrial gas turbines. These engines, which convert mechanical energy from a combusting air-fuel mixture into electrical energy, are widely used due to their efficiency and reliability. Unlike internal combustion engines, where fuel combustion occurs intermittently, gas turbines feature continuous combustion. Gas turbines can utilize various fuels, including natural gas and synthetic fuels. The ignition system In these engines is essential for initiating the combustion process. Spark discharge ignition systems are commonly used in industrial gas turbines. These systems generate an electrical spark to ignite the fuel-air mixture.

- The continuous combustion process in gas turbines ensures a steady power output, making them an attractive choice for power generation applications. The production of electricity from the hot gases generated during fuel combustion is a significant advantage of gas turbines. As the demand for cleaner and more efficient energy sources continues to grow, the market for industrial gas turbine ignition systems is expected to expand. In summary, industrial gas turbines are essential components in the power generation sector, and their ignition systems play a vital role in initiating the combustion process. Continuous combustion in gas turbines ensures a steady power output, making them a preferred choice for generating electrical energy.

Get a glance at the market report of share of various segments Request Free Sample

The Power generation segment was valued at USD 1.52 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

- APAC is estimated to contribute 28% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in the Asia Pacific region is experiencing significant growth due to the increasing demand for electricity and population expansion. According to industry reports, this region is the largest consumer of electricity, making it a major market for industrial gas turbine ignition systems. Hydrogen gas turbines have emerged as a viable solution for operating with diverse fuels, enhancing fuel efficiency and making industrial gas turbines a dependable combustion engine. The growing necessity for cleaner, more stable, and resilient electricity sources in the region is expected to boost the adoption of industrial gas turbine ignition systems in the energy sector.

These systems offer numerous advantages, including low greenhouse gas emissions, high efficiency, and long operational life, making them an attractive choice for power generation in the Asia Pacific market. The market is expected to witness steady growth during the forecast period, driven by the region's expanding energy needs and the shift towards cleaner energy sources.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Industrial Gas Turbine Ignition System Industry?

- Operational efficiencies associated with industrial gas turbines is the key driver of the market. Industrial gas turbines are the preferred choice for power generation and propulsion in various industries due to their efficiency, reliability, and compatibility with various fuel types. The ignition system is a crucial component of these gas turbines, responsible for initiating the combustion process In the engine's combustion chambers. The demand for industrial gas turbine ignition systems is directly linked to the market size and growth of industrial gas turbines. Gas turbines have seen significant advancements in design and performance, enabling them to handle increased loads while maintaining exceptional combustion efficiency and reducing emissions. The ignition system plays a vital role in this process, providing high-output signals to the igniter and exciter to ensure consistent and reliable ignition.

- The electrical system of the ignition system is responsible for generating and transmitting these signals, making it a critical element of the overall gas turbine system. The ignition system's performance is crucial to the efficient operation of industrial gas turbines. The igniter and exciter work together to produce a spark that ignites the fuel-air mixture In the combustion chamber. The ignition lead transfers the high-voltage electrical charge from the igniter to the spark plug, ensuring a reliable and consistent ignition. The ignition system's ability to perform under various operating conditions makes it an essential component of industrial gas turbines.

What are the market trends shaping the Industrial Gas Turbine Ignition System Industry?

Development of hybrid energy systems for gas turbines is the upcoming market trend.

- The market is experiencing significant growth due to the integration of hybrid energy systems in powering these turbines. Hybrid energy solutions, which combine multiple energy sources, are becoming increasingly popular as a means of reducing reliance on fossil fuels and decreasing carbon emissions. This trend is particularly relevant for industrial gas turbines, which can benefit from the use of waste heat and other forms of alternative energy. In the context of energy education, the adoption of cleaner sources is a priority for many industries. Homogeneous stoichiometric operation and EGR tolerance are essential features of modern industrial gas turbines, enabling them to operate efficiently with a wide range of fuel types.

- Peak pressure levels are also a critical consideration, as they impact the overall performance and efficiency of the turbine. Eco-friendly energy generation is a key focus for businesses seeking to minimize their carbon footprint and comply with environmental regulations. Hybrid energy systems offer a solution by allowing for the use of various energy sources, including renewable sources, to ensure consistent energy availability. Wide-open-throttle (WOT) operations are essential for industrial gas turbines, and hybrid energy systems can help maintain optimal performance levels during these periods. In summary, the market is witnessing growth due to the adoption of hybrid energy systems, which offer the benefits of reduced fossil fuel usage, decreased carbon emissions, and increased energy availability.

What challenges does the Industrial Gas Turbine Ignition System Industry face during its growth?

- Fluctuation in gasoline prices is a key challenge affecting the industry growth. The market experiences significant challenges due to the volatility in natural gas prices and electricity demand. Key industries such as food and beverage, chemicals, and offshore power generation rely on natural gas to operate their industrial gas turbines.

- The ignition system is a crucial component of these turbines. The unpredictability of natural gas prices and electricity demand can negatively impact the expansion of the industrial gas turbine market. The chemical sector, in particular, is a significant consumer of industrial gas turbines due to its energy-intensive processes. The instability in the demand for industrial gas turbines, coupled with the price fluctuations of natural gas, poses a challenge to market growth in the coming years.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- AECE GROUP

- Alta Industries Srl

- Ansaldo Energia Spa

- Champion Aerospace LLC

- Chentronics LLC

- General Electric Co.

- HOERBIGER Holding AG

- Kawasaki Heavy Industries Ltd.

- MAN Energy Solutions SE

- Meggitt Plc

- Mitsubishi Heavy Industries Ltd.

- Siemens AG

- Tenneco Inc.

- TESI GROUP spa

- Woodward Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Industrial gas turbines play a significant role in generating electrical power from various combustible fuels, including natural gas. The ignition system is a crucial component of these turbines, responsible for initiating the combustion process in the combustion chambers. The ignition system consists of igniters, exciters, ignition leads, and spark plugs. High-output signals from the electrical system are essential for ignition lead voltage, which triggers the igniter to produce a spark. The igniter, in turn, generates a spark discharge that ignites the fuel-air mixture in the combustion chamber. The exciter produces high-frequency electrical current to power the igniter. The ignition system's efficiency is vital for eco-friendly energy generation, as it directly impacts the combustion process's homogeneous stoichiometric operation, wide-open-throttle (WOT) performance, and peak pressure levels.

Furthermore, modern ignition systems ensure cleaner sources of energy by adhering to EGR tolerance and minimizing greenhouse gas emissions. Industrial gas turbines are used in various applications, such as power generation, waste heat recovery, and mechanical drive in heavy-duty and light-duty gas turbines. The global power investment trend is shifting towards cleaner, more efficient energy sources, making the market a growing sector. Ignition system components, including igniters, exciters, and leads, are essential for maintaining the service life of equipment and machinery in the power generation sector. The demand for electrical energy and the shale gas boom have led to increased investment in gas-fired power plants, further fueling the growth of the market.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

151 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 10.03% |

|

Market growth 2024-2028 |

USD 2.13 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

8.88 |

|

Key countries |

US, China, India, Brazil, and Germany |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.