Spherical Aluminum Oxide Market Size 2024-2028

The spherical aluminum oxide market size is forecast to increase by USD 141 million at a CAGR of 6.4% between 2023 and 2028.

- The market is experiencing significant growth due to the expanding automotive sector and the development of next-generation batteries. The automotive industry's increasing demand for lightweight and high-performance batteries is driving the market's growth. Additionally, spherical aluminum oxide's use In the production of advanced lithium ion batteries is a key trend In the market. However, the high production cost associated with spherical aluminum oxide remains a significant challenge for market growth. Producers are exploring ways to reduce costs through technological advancements and economies of scale. Overall, the market is poised for growth, with opportunities arising from the automotive and energy storage industries.

What will be the Size of the Market During the Forecast Period?

- The market encompasses the global trade of inorganic spherical Al2O3, an essential high hardness compound with the chemical formula Al2O3. Known for its high melting and boiling points, this ionized crystal exhibits unique properties, making it a sought-after material in various industries. Refractory materials, industrial alumina, and high-purity aluminum oxide are primary applications for this versatile compound. Sourced from natural resources like bauxite and diaspore, spherical aluminum oxide undergoes chemical methods to produce isomorphous crystals and crystal forms, such as high sphericity ?-phase alumina. Spherical aluminum oxide's high filling density, large particle diameter, and low viscosity make it an ideal filler for rubber, plastics, and ceramic raw materials.

- Its high purity and particle size distribution contribute to its widespread use in various industries, including electronics, aerospace, and automotive, where low viscosity and high temperature resistance are essential. The market continues to grow due to increasing demand for high-performance materials in various industries. With ongoing research and development efforts, this market is expected to expand further, offering significant opportunities for growth.

How is this Industry segmented and which is the largest segment?

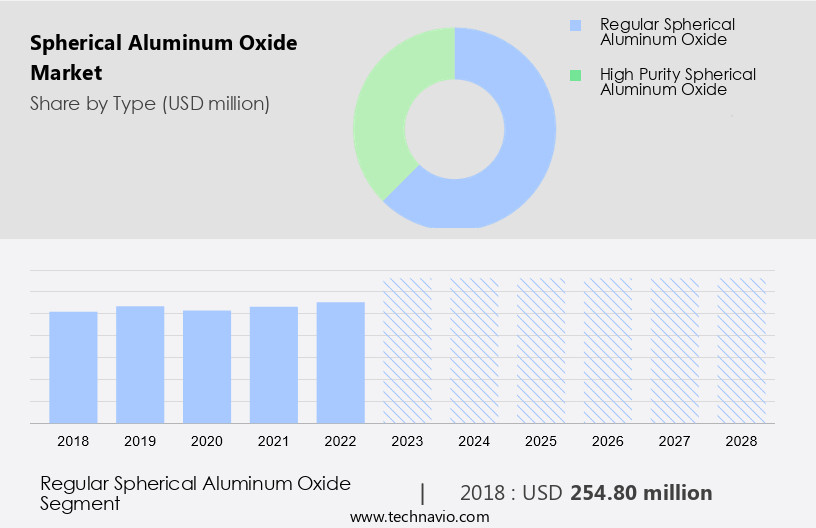

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- Regular spherical aluminum oxide

- High purity spherical aluminum oxide

- Application

- Electronics

- Automotive

- Aerospace

- Healthcare

- Others

- Geography

- APAC

- China

- India

- Japan

- South Korea

- North America

- Canada

- US

- Europe

- Germany

- UK

- France

- Italy

- South America

- Middle East and Africa

- APAC

By Type Insights

- The regular spherical aluminum oxide segment is estimated to witness significant growth during the forecast period.

Spherical aluminum oxide, or alumina spheres, is a high-performing inorganic substance with the chemical formula Al2O3. Known for its high hardness and refractoriness, this compound is widely utilized in various industries due to its unique properties. With a melting point of 2045°C and a boiling point of 2980°C, aluminum oxide is an ionized crystal that performs optimally under high-temperature conditions. Regular spherical aluminum oxide is particularly valued for its consistent shape and uniform particle size, which contribute to its superior filling density and large particle diameter. These properties make it an excellent choice for use as a filler in rubber, plastics, and ceramic raw materials.

Get a glance at the market report of share of various segments Request Free Sample

The regular spherical aluminum oxide segment was valued at USD 254.80 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

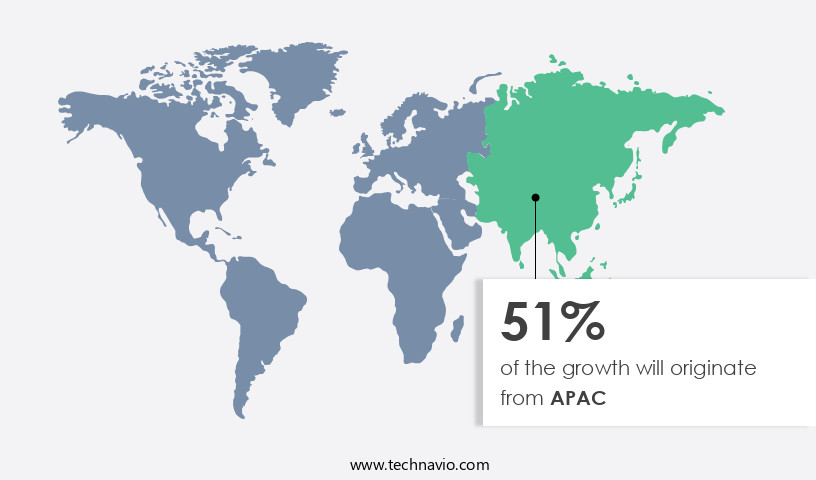

- APAC is estimated to contribute 51% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The Asia Pacific region exhibits a prominent market for spherical aluminum oxide due to the expanding industrial sector, particularly In the automotive and renewable energy industries. Spherical aluminum oxide, a high hardness compound with the chemical formula Al2O3, is a crucial refractory material used in various industries. Its high melting point (2015°C) and boiling point (2983°C) make it suitable for high-temperature applications. The automotive industry's growth in Asia Pacific significantly influences the demand for spherical aluminum oxide.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Spherical Aluminum Oxide Industry?

Growth in automotive sector is the key driver of the market.

- The global market for spherical aluminum oxide is experiencing significant growth due to its increasing utilization in various industries, particularly In the automotive sector. This inorganic substance, with the chemical formula Al2O3, is renowned for its high hardness and high melting point, making it an ideal choice for refractory materials. In the automotive industry, spherical aluminum oxide is employed for enhancing the mechanical properties of aluminum alloys through the integration of its nanoparticles. This results in lighter and stronger automotive components, contributing to the industry's objectives of improving fuel efficiency, reducing emissions, and complying with stringent regulatory standards. Furthermore, spherical aluminum oxide nanoparticles play a vital role in catalytic converters as a catalyst support, boosting their catalytic efficiency and facilitating the conversion of harmful pollutants into less harmful substances.

- This enhancement is crucial for the development of lower-emission vehicles, aligning with the industry's focus on sustainability and environmental responsibility. In addition to automotive applications, spherical aluminum oxide is also widely used as a filler in rubber, plastics, and ceramic raw materials, offering high filling density and large particle diameter with a controlled particle size distribution. Its low viscosity and good fluidity make it an excellent choice for these applications, ensuring optimal performance and consistency. Spherical aluminum oxide is also used in high-temperature applications, such as in coatings, catalyst supports, and nanoparticles (NPs). The thermal decomposition of aluminum oleate, derived from oleic acid and used as a stabilizing agent, results In the formation of spherical aluminum oxide NPs.

What are the market trends shaping the Spherical Aluminum Oxide Industry?

Development of next-generation batteries is the upcoming market trend.

- The global market for spherical aluminum oxide is experiencing notable expansion due to its essential function In the production of advanced aluminum-based batteries. These batteries are gaining popularity for their distinctive features, such as high volumetric and competitive gravimetric capacity, and the presence of trivalent charge carriers. These attributes make aluminum-based batteries a favorable choice for rechargeable energy storage systems, representing a promising contender In the energy storage industry. Spherical aluminum oxide is a key contributor to this technological progression. Its distinctive spherical form enhances the structural stability and efficiency of battery components. This shape enables superior ion transport, a critical factor in battery performance.

- The inorganic substance, with the chemical formula Al2O3, is a high hardness compound with a melting point of approximately 2050°C and a boiling point of around 2980°C. It forms ionized crystals at high temperatures, making it an ideal choice for refractory materials. In the industrial sector, spherical aluminum oxide is utilized as a filler in rubber, plastics, and ceramic raw materials. Its high filling density and large particle diameter, along with a well-defined particle size distribution, contribute to its excellent performance In these applications. Additionally, its low viscosity and good fluidity make it a valuable component In the production of coatings, catalyst supports, and high-temperature applications.

What challenges does the Spherical Aluminum Oxide Industry face during its growth?

High production cost associated with spherical aluminum oxide is a key challenge affecting the industry growth.

- The market is driven by its unique properties as a high hardness compound with a chemical formula of Al2O3. This inorganic substance is widely used in various industries due to its high melting point and boiling point, making it an ideal choice for refractory materials. The production of spherical aluminum oxide, particularly high-purity y-Al2O3, involves a complex and intricate process. This process includes stages such as sol preparation, spherical support formation, neutralization in oil, crystallization in aqueous ammonia solution, and subsequent drying and calcining. Each step requires precise control of temperature, pressure, and pH to ensure the desired properties, including specific surface area, pore volume, and compression strength.

- The cost of producing spherical alumina ranges from approximately USD2 to USD10 per kilogram, depending on the purity grade and particle size. Its applications span across industries, including industrial alumina production from bauxite and diaspore, filler for rubber, plastics, and ceramic raw materials, high filling density in coatings and catalyst supports, and high-temperature applications. Spherical alumina is also used In the production of nanoparticles (NPs) via thermal decomposition, which are employed in various fields such as electronics, catalysis, and biomedicine. The synthesis of spherical aluminum oxide involves various techniques, including chemical methods, isomorphous crystals, and crystal forms. The final product undergoes morphological and crystallinity changes during crystallization, annealing, and phase transition, as evidenced by X-ray diffraction, transmission electron microscopy, and X-ray photoelectron spectroscopy.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Advanced Engineering Materials Ltd.

- Aritech Chemazone Pvt. Ltd.

- Atlantic Equipment Engineers Inc.

- ATT Advanced elemental materials Co Ltd

- Bestry

- Denka Co. Ltd.

- Hebei Suoyi New Material Technology Co Ltd.

- Heeger Materials Inc.

- Hunan Fushel Technology Ltd

- Lumi-m

- Novoray

- Panadyne Inc.

- SCR Sibelco NV

- SkySpring Nanomaterials Inc.

- The Metal Powder Co. Ltd.

- US Research Nanomaterials Inc.

- xtra GmbH

- Zhengzhou Haixu Abrasives Co Ltd

- ZIBO LITUO COMPOSITE Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The inorganic substance with the chemical formula Al2O3 is a high hardness compound widely used in various industries due to its exceptional properties. This refractory material, also known as industrial alumina, is derived from bauxite ore through a series of chemical methods. The melting point and boiling point of Al2O3 are high, making it suitable for high-temperature applications. Alumina exists in different crystal forms, including isomorphous crystals and ?-phase alumina. Spherical alumina, specifically, is known for its high sphericity, which makes it an ideal filler for various industries. In the realm of rubber and plastics, spherical alumina provides high filling density and excellent compatibility, enhancing the mechanical properties of the final product.

In addition, as a ceramic raw material, alumina is extensively used In the production of advanced ceramic materials. Its large particle diameter and specific particle size distribution contribute to its low viscosity and good fluidity during the manufacturing process. The high-temperature stability and excellent thermal properties make it a preferred choice for various applications. Nanoparticles (NPs) of Al2O3, particularly, have gained significant attention due to their unique properties. These NPs undergo thermal decomposition at high temperatures, resulting in morphological and crystallinity changes. Aluminum oleate, a derivative of oleic acid and a stabilizing agent, is often used In the synthesis of spherical alumina NPs.

Moreover, the production process of spherical alumina involves several stages, including crystallization, annealing, and phase transition. X-ray diffraction and transmission electron microscopy are essential analytical techniques used to study the crystalline structure and morphology of spherical alumina. The chemical composition of spherical alumina can be analyzed using techniques such as X-ray photoelectron spectroscopy and monolayer assembly on quartz substrates. Organic linker molecules are often employed to modify the surface properties of spherical alumina for specific applications. Spherical alumina exhibits excellent optical band gap properties and transmittance properties, making it a valuable component in coatings and catalyst supports.

Furthermore, its applications extend to various high-temperature applications, further highlighting its importance In the industrial sector. The production process of spherical alumina involves several stages, including crystallization, annealing, and phase transition, which can be studied using advanced analytical techniques. The material's exceptional properties make it a valuable asset In the industrial sector, particularly in high-temperature applications.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

205 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6.4% |

|

Market growth 2024-2028 |

USD 141 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

5.0 |

|

Key countries |

US, China, Japan, India, Germany, South Korea, Canada, UK, France, and Italy |

|

Competitive landscape |

Leading Companies, market growth and forecasting, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the Spherical Aluminum Oxide industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.