Vortex Flowmeter Market Size 2025-2029

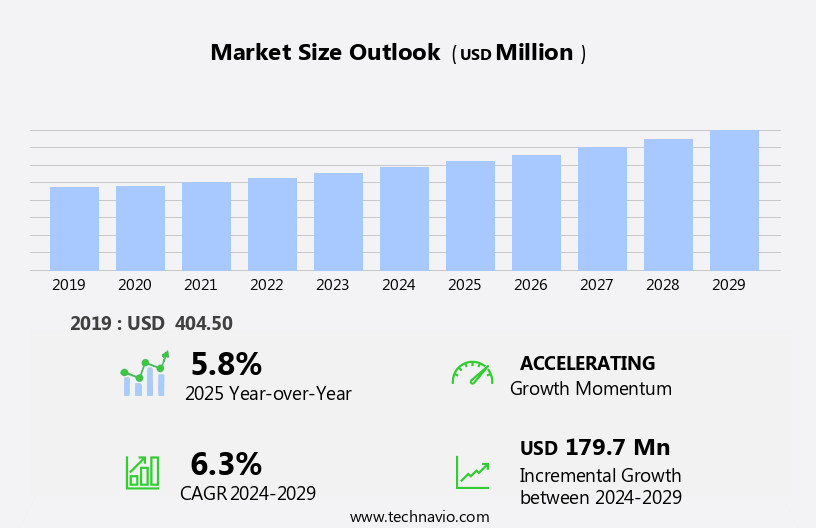

The vortex flowmeter market size is forecast to increase by USD 179.7 million at a CAGR of 6.3% between 2024 and 2029.

- The market is experiencing significant growth, driven primarily by the expansion of oil terminals and the increasing demand for accurate and efficient flow measurement solutions. This expansion creates a heightened need for reliable flowmeters, such as vortex flowmeters, to ensure the safe and efficient transfer of oil and other liquids. Moreover, the trend towards smart vortex flowmeters, which offer advanced features like real-time monitoring and remote access, is gaining momentum. These intelligent devices enable better process control, predictive maintenance, and data-driven decision-making, making them increasingly popular in various industries, including oil and gas, water and wastewater, and chemical processing. The market is also witnessing technological advancements, including digitalization and automation, which are leading to minimal maintenance and higher operational efficiency.

- However, the market faces technical challenges that must be addressed to fully capitalize on its growth potential. Regulatory hurdles, such as stringent approval processes and compliance requirements, can impact adoption. Additionally, supply chain inconsistencies and the need for customized solutions can add complexity to the market landscape. However, the market also faces challenges, such as the technical difficulties associated with vortex flowmeters in certain applications, including the presence of turbulence and non-uniform flow conditions. Companies seeking to capitalize on market opportunities must navigate these challenges effectively by investing in research and development, collaborating with regulatory bodies, and fostering strong supplier relationships. By doing so, they can position themselves as innovative market leaders and meet the evolving demands of their customers.

What will be the Size of the Vortex Flowmeter Market during the forecast period?

- The market exhibits dynamic activity, driven by advancements in flowmeter technology and integration with control systems. Installation of flowmeters is a significant investment, necessitating careful ROI analysis and selection based on application and flow conditions. Flowmeter data acquisition and logging play a crucial role in optimizing performance and ensuring compliance with industry standards. Flowmeter manufacturers continue to innovate, developing new software solutions for data analysis, modeling, and automation. Maintenance and calibration are essential for accurate and reliable flow measurement, while certifications ensure compliance with regulatory requirements. Pricing and cost-benefit analysis are critical factors in flowmeter procurement, with remote monitoring and troubleshooting capabilities offering added value. These meters can be easily integrated with industrial automation systems, allowing for real-time data analysis and flow rate measurement.

- Flowmeter research and development focus on improving accuracy, reducing installation and maintenance costs, and expanding application areas. Integration with other systems, such as SCADA and ERP, is a growing trend, enabling real-time data analysis and streamlined operations. Flowmeter data analysis and modeling help optimize processes and improve efficiency, while simulation tools facilitate design and testing. Flowmeter standards and certifications ensure interoperability and accuracy, enabling seamless integration into complex systems. With increasing demand for reliable and accurate flow measurement, the market for flowmeters continues to evolve, offering opportunities for growth and innovation.

How is this Vortex Flowmeter Industry segmented?

The vortex flowmeter industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- End-user

- Oil and gas industry

- Power industry

- Chemical and petrochemical

- Food and beverage

- Others

- Type

- Inline vortex flowmeter

- Massflow vortex flowmeter

- Insertion vortex flowmeter

- Application

- Liquids

- Gases

- Steam

- Corrosive fluids and slurries

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South America

- Brazil

- Rest of World (ROW)

- North America

By End-user Insights

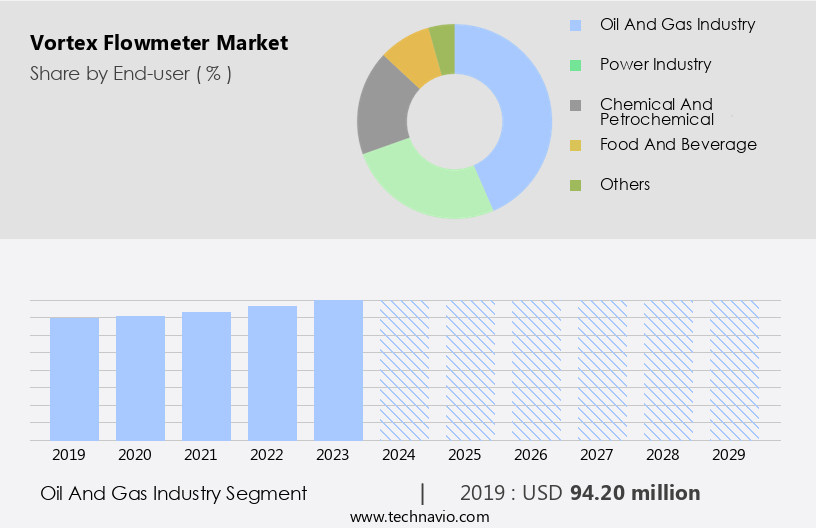

The oil and gas industry segment is estimated to witness significant growth during the forecast period. In the dynamic world of industrial process control, flowmeters play a pivotal role in various sectors, including oil and gas. These instruments are indispensable in applications such as water injection, test and production separation, disposal wells, hydraulic fracturing, natural gas pipelines, and chemical injections. Among the diverse types of flowmeters, vortex flowmeters have gained significant traction due to their ability to ensure optimal flow rate in the transport of liquids and gases through pipelines. Vortex shedding, a phenomenon that occurs when a fluid flows over a bluff body, is the principle behind vortex flowmeters. In the oil and gas sector, vortex flowmeters play a crucial role in various applications, including water injection, test and production separation, disposal wells, hydraulic fracturing, natural gas pipelines, and chemical injections. These meters provide accurate measurements by detecting the frequency of vortex shedding, which is influenced by the flow rate and fluid properties.

In the oil and gas industry segment, vortex flowmeters are particularly valuable due to their robustness and reliability in harsh environmental conditions. Water treatment applications also benefit from vortex flowmeters, as they provide precise flow measurements for processes such as wastewater treatment and water distribution. This trend is particularly noticeable in the power generation sector, where natural gas is replacing coal-fired plants. In power generation, these meters are essential for monitoring and controlling the flow of fluids in thermal and hydroelectric power plants. Industrial automation and process control systems rely on vortex flowmeters for efficient flow management and regulation. Furthermore, vortex flowmeters are utilized in various industries, including food and beverage, chemical processing, and pharmaceuticals, to ensure the accurate measurement and control of fluid flow.

The Oil and gas industry segment was valued at USD 94.20 million in 2019 and showed a gradual increase during the forecast period. The market for vortex flow meters is expected to continue growing due to increasing demand for smart metering solutions and the need for flow meter calibration services. In the context of flow optimization, these meters enable cost savings by reducing energy consumption and minimizing waste. Magnetic flowmeters and ultrasonic flowmeters are alternative technologies, but vortex flowmeters offer advantages such as a wider flow range, lower installation costs, and ease of maintenance. Additionally, vortex flowmeters provide flow validation capabilities, ensuring the accuracy and reliability of flow measurements. Vortex flowmeters are a crucial component in various industries, including oil and gas, water treatment, power generation, and industrial automation, due to their ability to accurately measure and control fluid flow. Their robustness and reliability make them an ideal choice for harsh industrial environments.

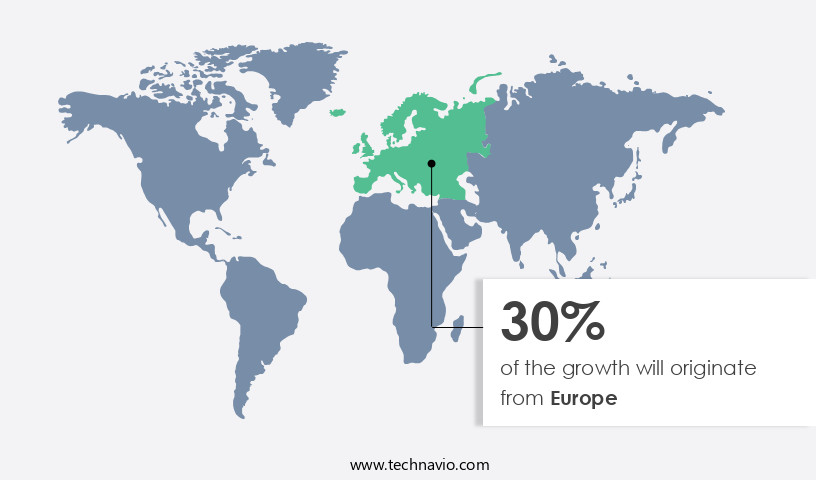

Regional Analysis

Europe is estimated to contribute 30% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The European oil and gas industry is witnessing significant growth due to the increasing number of pipeline projects aimed at supplying natural gas. This expansion in midstream and downstream projects will increase natural gas consumption in Europe, as the region transitions from coal-based power generation to natural gas. Furthermore, safety concerns following accidents at natural gas plants have highlighted the importance of advanced flow measurement technologies in ensuring safe operations. Consequently, industrial operators are adopting electronic flow measurement devices, such as vortex flowmeters, to meet the safety integrity levels required during production. The expansion of oil terminals globally, which serve as storage centers and transportation hubs for crude oil and petroleum products, drives the demand for vortex flowmeters and fluid handling systems in the mid-stream and downstream sectors of the oil and gas industry. Vortex flowmeters, including vortex shedding sensors, are increasingly being used for flow measurement in various industries, including oil and gas, water treatment, power generation, and chemical processing.

These devices offer advantages such as high accuracy, reliability, and flexibility in measuring flow rates across a wide range. In addition, they are suitable for measuring both liquid and gas flows, making them a popular choice for industries dealing with fluid flow. Moreover, the adoption of vortex flowmeters is not limited to the oil and gas sector. They are also used in industries like food and beverage, where flow measurement is crucial for process control and optimization. The integration of vortex flowmeters into industrial automation systems enables real-time flow monitoring, analysis, and regulation, leading to improved flow efficiency and cost savings.

In the context of power generation, vortex flowmeters are used for flow measurement in gas turbines, ensuring optimal performance and efficiency. They are also employed in flow validation processes to ensure accurate and consistent flow data for calibration and maintenance purposes. In summary, the increasing demand for natural gas in Europe, coupled with the need for safety and efficiency, is driving the adoption of advanced flow measurement technologies like vortex flowmeters across various industries. These devices offer advantages such as high accuracy, reliability, and flexibility, making them an essential component of industrial flow management and optimization.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Vortex Flowmeter market drivers leading to the rise in the adoption of Industry?

- The expansion of oil terminals is a significant driver for the increasing demand in the market for vortex flowmeters, which are essential tools for accurately measuring and managing the flow rate of oil and other liquids in such facilities. Vortex flowmeters play a crucial role in pipeline applications, serving various industries such as oil and gas, water treatment, and process industries. The expansion of oil terminals globally has driven the demand for these flowmeters and fluid handling systems, as they are essential for mid-stream and downstream activities in the oil and gas sector. Oil terminals facilitate the storage and transportation of crude oil and petroleum products, making them vital components of the oil and gas supply chain. Despite the challenges faced by upstream activities due to low oil and gas prices in recent years, the high consumption pattern of these resources has necessitated the need for robust pipeline infrastructure.

- Vortex flowmeters, including coriolis flowmeters and magnetic flowmeters, are employed for precise flow rate measurement and flow optimization in these applications. These flowmeters provide accurate flow signals for effective flow management and flow validation, contributing significantly to the overall efficiency and productivity of industrial processes. Their integration with communication protocols and software platforms enables data exchange, enabling operational efficiency and process optimization.

What are the Vortex Flowmeter market trends shaping the Industry?

- The increasing demand for smart vortex flowmeters represents a significant market trend. These advanced flowmeters offer enhanced features and improved accuracy, making them a popular choice for various industries. Vortex flowmeters, a sophisticated flow measurement technology, have gained significant traction in various industries due to their ability to ensure flow integrity and reliability. These flowmeters utilize the principle of vortex shedding, where the flow disturbance creates a series of vortices, which are then measured to determine the flow rate. Smart vortex flowmeters, an advanced variant, offer additional features, such as energy measurement through an analog input and edge-computing technology for enhanced functionality. The primary objective of smart vortex flowmeters is to provide continuous flow data, even in remote locations, for streamlined process control.

- They are easy to install and eliminate the need for discrete flow computers. These flowmeters are connected via HART communication protocols, enabling real-time monitoring in remote configurations. Applications of smart vortex flowmeters span across industries like oil and gas, mining, and power generation, where precise flow measurement and control are crucial. The technology's ability to provide reliable and accurate flow data, coupled with its ease of installation and integration with existing systems, makes it a preferred choice for industrial automation and flow regulation.

How does Vortex Flowmeter market faces challenges face during its growth?

- The growth of the industry is significantly impacted by the technical challenges posed by vortex flowmeters. These instruments present complex issues that must be addressed to ensure accurate and reliable measurements in various applications. Overcoming these challenges is essential for advancing the technology and expanding its use in process control and measurement systems. Vortex flowmeters are an essential tool for flow sensing and monitoring in various industries, including food and beverage. These meters operate by detecting the pressure pulses created by the shedding of vortices as a fluid flows over a bluff body. However, their effectiveness is limited in applications with low flow rates or high viscosity liquids due to insufficient pressure pulse generation. When considering installation, it's crucial to evaluate the medium type, pipe diameter, and symmetrical flow velocity profile. For instance, measuring highly viscous fluids like sludge and slurries may cause the bluff body to get covered, impacting measurement accuracy.

- To ensure precise flow measurement and optimal performance, it's essential to understand the process conditions thoroughly before installing a vortex flowmeter. Additionally, proper installation and regular calibration are vital for maintaining accurate flow data and effective process control. Ultrasonic flowmeters and variable area flowmeters are alternative options for applications where vortex flowmeters may not be suitable. Proper selection and installation of the appropriate flowmeter technology can significantly improve process efficiency and reduce operational costs.

Exclusive Customer Landscape

The vortex flowmeter market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the vortex flowmeter market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, vortex flowmeter market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

ABB Ltd. - The company offers VortexMaster FSV430, a versatile metering solution for volume flow applications, available in both flange-mount and wafer-type designs.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABB Ltd.

- Azbil Corp.

- Badger Meter Inc.

- Beijing Gallop Technology Co. Ltd.

- Dover Corp.

- Emerson Electric Co.

- Endress Hauser Group Services AG

- General Electric Co.

- Honeywell International Inc.

- ifm electronic gmbh

- KROHNE Messtechnik GmbH

- Parker Hannifin Corp.

- RS Hydro Ltd.

- Schneider Electric SE

- Siemens AG

- Sierra Instruments Inc.

- TLV Co. Ltd.

- Yokogawa Electric Corp.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Vortex Flowmeter Market

- In January 2024, Emerson Electric Company, a leading provider of flow measurement solutions, introduced the Micro Motion Coriolis 6400 Series vortex flowmeter. This new product line offers enhanced accuracy and reliability, targeting the oil and gas, power, and chemical industries (Emerson Electric Company Press Release).

- In March 2025, ABB and Hach Company announced a strategic partnership to integrate ABB's vortex flowmeters with Hach's water and wastewater solutions. This collaboration aims to improve process efficiency and water quality management in various industries (ABB Press Release).

- In October 2024, Endress+Hauser, a global flow measurement specialist, completed the acquisition of Blue-White Industries, a US-based manufacturer of vortex flowmeters. This acquisition strengthened Endress+Hauser's presence in the North American market and expanded its product portfolio (Endress+Hauser Press Release).

Research Analyst Overview

The market continues to evolve, driven by the diverse applications across various sectors such as power generation, industrial automation, and flow cost optimization in industries like oil and gas, water treatment, and food and beverage. Vortex shedding technology, a key component of vortex flowmeters, plays a crucial role in ensuring flow integrity and reliability. These meters measure the flow rate of liquids and gases by detecting the frequency of vortex shedding, which occurs when a fluid flows through a constriction. Vortex flowmeters offer advantages such as high accuracy, repeatability, and stability, making them a preferred choice for flow measurement and regulation in power generation and industrial automation applications.

The Vortex Flowmeter Market is growing as industries seek precise measurement solutions for gas flow and liquid flow applications. Advanced vortex sensors enhance flow detection and flow control, ensuring efficiency. Compared to traditional methods like turbine flowmeters and variable area flowmeters, vortex technology offers greater accuracy. Competing instruments such as magnetic flowmeters, ultrasonic flowmeters, differential pressure flowmeters, mass flowmeters, and Coriolis flowmeters cater to diverse needs. Integrating flow transmitters, flow switches, and flow indicators optimizes monitoring systems. Regular flow calibration improves flow accuracy, ensuring flow repeatability and flow stability. As industries expand, technological advancements and increasing adoption are driving innovation in the Vortex Flowmeter Market for enhanced measurement precision.

The Vortex Flowmeter Market is advancing rapidly with innovations in flowmeter selection, flowmeter installation, and flowmeter maintenance to enhance operational efficiency. Regular flowmeter calibration and effective flowmeter troubleshooting ensure accurate measurements, while emerging flowmeter trends drive industry evolution. Compliance with flowmeter certifications strengthens credibility among flowmeter suppliers, influencing flowmeter pricing and boosting flowmeter cost-benefit analysis for optimal flowmeter ROI. Advanced flowmeter data logging enables real-time insights, supporting flowmeter integration, flowmeter automation, and flowmeter remote monitoring capabilities. Enhanced flowmeter control systems, flowmeter software, flowmeter simulation, and flowmeter modeling refine performance. As demand grows, technological advancements continue to shape this market, ensuring precision and efficiency across diverse applications.

The technology's ability to measure mass flow, density, and temperature makes it suitable for use in various industries, including oil and gas, water treatment, and chemical processing. Vortex flowmeters are also used for flow optimization and monitoring in applications like flow data analysis and calibration. The technology's versatility and adaptability enable it to cater to a wide flow range, from low to high flow rates, making it a valuable asset in various industries. Furthermore, vortex flowmeters ensure flow safety by providing real-time flow data, enabling operators to maintain optimal flow conditions and prevent potential hazards. The technology's reliability and efficiency contribute to cost savings and improved process control, making it an essential tool for flow management and regulation. The market's continuous dynamism is reflected in its applications across various sectors, including power generation, industrial automation, oil and gas, water treatment, and food and beverage industries. The technology's ability to ensure flow integrity, reliability, and cost savings makes it a valuable asset for flow measurement, optimization, and regulation.

Dive into Technavio's strong research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Vortex Flowmeter Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

238 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6.3% |

|

Market growth 2025-2029 |

USD 179.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

5.8 |

|

Key countries |

US, China, Germany, UK, Japan, France, Canada, India, Brazil, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Vortex Flowmeter Market Research and Growth Report?

- CAGR of the Vortex Flowmeter industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across Europe, North America, APAC, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the vortex flowmeter market growth of industry companies

We can help! Our analysts can customize this vortex flowmeter market research report to meet your requirements.