2D And 3D Machine Vision Systems Market Size 2024-2028

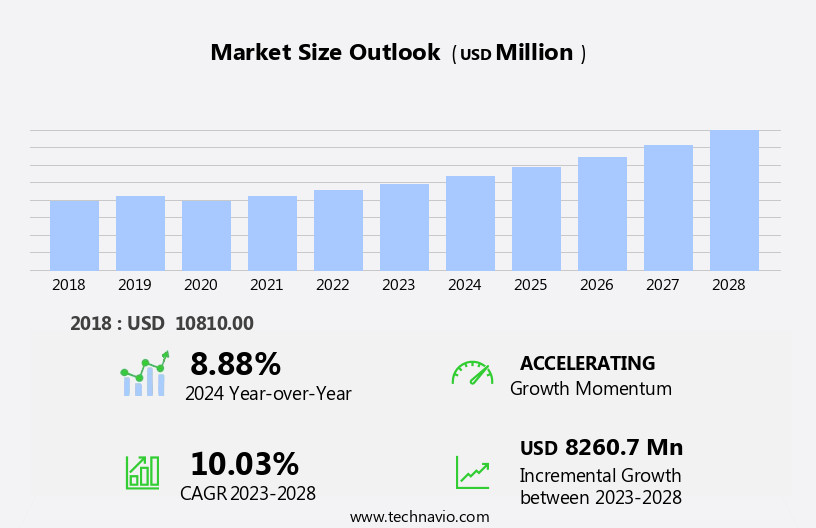

The 2d and 3d machine vision systems market size is forecast to increase by USD 8.26 billion at a CAGR of 10.03% between 2023 and 2028.

- The market is witnessing significant growth due to the increasing automation in various industries such as pharmaceuticals, food and beverage, and consumer electronics. One of the key trends driving market growth is the development of 3D mapping and modeling technologies, which are increasingly being used in applications like 3D systems for medical devices, glass manufacturing, and display production. Additionally, advancements in artificial intelligence (AI) and machine learning (ML) are enabling the creation of more sophisticated sensor systems, improving accuracy and efficiency in industries like chocolate manufacturing.

- However, a lack of efficient system operators remains a challenge for market growth. In the US and North America, the market is expected to see continued growth in sectors like electronics, where 3D technology is being used in tablets and computer components.

What will be the Size of the 2D And 3D Machine Vision Systems Market During the Forecast Period?

- The market encompasses advanced imaging technologies that enable automated inspection and process control in various industries. Leveraging computer technology, these systems employ cameras, image processing algorithms, and machine learning techniques to analyze 2D plan views and 3D models of products. Machine vision systems are increasingly adopted for high-speed production lines in sectors such as pharmaceuticals and food processing, ensuring product quality and reducing machine downtime. 3D systems offer enhanced capabilities, including object recognition in complex environments and the detection of surface defects. These systems are particularly valuable in industries with hazardous conditions, where human intervention is limited. Artificial intelligence and machine learning algorithms are integral components of modern machine vision systems, enabling improved accuracy and flexibility.

- Camera technology, including camera lenses and light sources, plays a crucial role in machine vision systems' performance. The integration of machine vision systems into automated systems has led to increased productivity and streamlined processes, making them indispensable in industries that require stringent quality control and process control.

How is this 2D And 3D Machine Vision Systems Industry segmented and which is the largest segment?

The 2d and 3d machine vision systems industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Technology

- 2D Machine vision systems

- 3D machine vision systems

- Geography

- APAC

- China

- Japan

- North America

- US

- Canada

- Europe

- Germany

- UK

- Middle East and Africa

- South America

- APAC

By Technology Insights

The 2d machine vision systems segment is estimated to witness significant growth during the forecast period. Machine vision systems, driven by computer technology and automation, have become essential components in various industries for material quality inspection and process control. Two-dimensional (2D) machine vision systems, utilizing 2D cameras and video cameras, dominate the market due to their cost-effectiveness and ease of use. These systems are widely adopted in sectors like food and beverage, medical devices, pharmaceuticals, automotive, electronics, and semiconductors for automated inspection of components and identifying microscopic defects. 2D systems help enhance productivity and minimize machine downtime, making them preferred choices over more complex and expensive 3D machine vision systems. Computer vision algorithms, including AI and machine learning (ML), are integrated into these systems to improve quality and yield.

Standard operating systems, interface protocols, and smart cameras are essential hardware and software components of 2D machine vision systems. The market for 2D and 3D machine vision systems is expected to grow significantly due to increasing demand for high-speed production lines, inspection in hazardous environments, and the integration of advanced technologies like AI algorithms, ML, and frame grabbers. Industries such as consumer electronics, medical and pharmaceuticals, and advanced manufacturing partnerships are expected to fuel this growth. Vision sensors, communication systems, and X-ray scanners are additional components that expand the functionality of these systems.

Get a glance at the share of various segments Request Free Sample

The 2D Machine vision systems segment was valued at USD 6.17 billion in 2018 and showed a gradual increase during the forecast period.

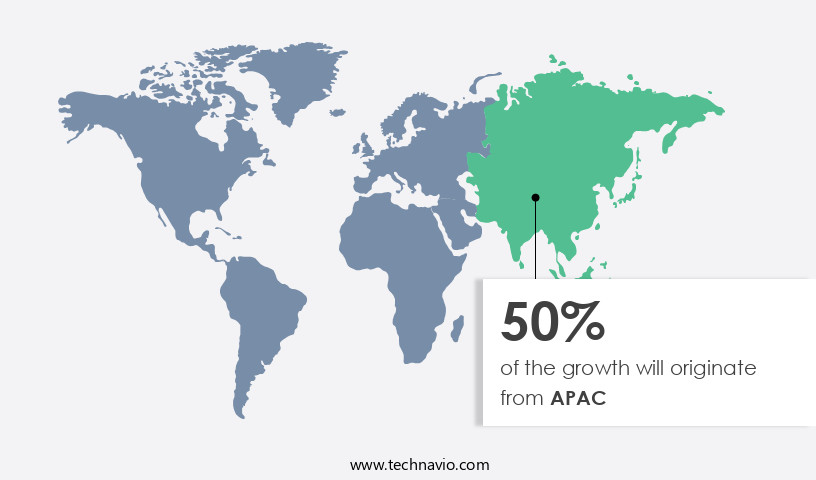

Regional Analysis

APAC is estimated to contribute 50% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The market is experiencing significant growth in APAC, driven by the region's robust industrial sector, particularly in industries such as chemical, automotive, food and beverage, healthcare, and utilities. Rapid urbanization and population growth are fueling the demand for automated quality assurance and inspection systems, including 2D and 3D machine vision systems. These systems enable operators to make informed decisions in real-time, ensuring regulatory compliance, enhancing plant performance, and maintaining consistent product quality. Machine vision systems, comprising 2D cameras, frame grabbers, vision sensors, and communication systems, are integral to various applications, from chocolate inspection on production lines to material quality control in consumer electronics and medical pharmaceuticals.

Computer technology, AI algorithms, machine learning, and advanced manufacturing partnerships are key trends shaping the market's evolution. Integrating smart cameras, hardware, software, and standard operating systems, these systems support various industries in reducing machine downtime, improving process control, and increasing productivity.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of 2D And 3D Machine Vision Systems Industry?

- Increasing investments in machine vision technology is the key driver of the market.The demand for machine vision systems has grown significantly due to the increasing emphasis on product quality and efficiency in manufacturing processes. Companies are increasingly investing in advanced 2D and 3D machine vision systems to automate quality assurance and reduce production costs. These systems utilize cameras, image processing technology, and computer technology to inspect materials in both 2D plan view and 3D. This is particularly important in industries such as Consumer Electronics, Medical and Pharmaceuticals, and Advanced Manufacturing Partnerships, where high-speed production lines and hazardous environments necessitate automated inspection. Machine learning algorithms and AI are also being integrated into machine vision systems to increase productivity and reduce machine downtime.

- The market for machine vision systems includes hardware such as cameras, camera lenses, light sources, frame grabbers, and vision sensors, as well as software for image processing and communication systems. Other technologies such as X-ray scanners and smart cameras are also gaining popularity in various industries. Overall, the market for machine vision systems is expected to continue growing as more companies adopt these systems to improve their manufacturing processes and ensure consistent material quality.

What are the market trends shaping the 2D And 3D Machine Vision Systems Industry?

- Development of 3D medical display systems is the upcoming market trend. Machine vision systems, which integrate cameras, image processing, and computer technology, have become essential components of automated production lines in various industries, including consumer electronics and medical and pharmaceuticals. Traditional 2D machine vision systems, utilizing 2D cameras and computer-based vision software, are commonly used for material quality inspection on high-speed production lines. However, the need for increased productivity and decreased machine downtime has led to the development of advanced 3D machine vision systems. These systems employ AI algorithms and machine learning to analyze images in a more comprehensive manner, enabling more precise inspection and process control. 3D systems, such as frame grabbers and vision sensors, utilize smart cameras, hardware, and software to capture and process data in real-time.

- Communication systems and X-ray scanners are also integrated into these systems for enhanced functionality. The Advanced Manufacturing Partnership, a collaborative effort between industry, academia, and government, is driving the research and development of these advanced technologies. Computer technology continues to play a crucial role in the evolution of machine vision systems, with standard operating systems and interface protocols ensuring seamless integration with various industrial applications. AI algorithms and machine learning are increasingly being employed to improve quality and yield, with applications ranging from chocolate inspection to intelligent transportation systems.

What challenges does the 2D And 3D Machine Vision Systems Industry face during its growth?

- Lack of efficient system operators is a key challenge affecting the industry growth. Machine vision systems, which incorporate cameras, image processing technology, and computer automation, are increasingly being adopted in various industries for material quality inspection and process control. Both 2D and 3D systems are gaining popularity due to their ability to enhance productivity and reduce material waste in high-speed production lines. In the metal fabrication sector, for instance, 2D plan view systems using 2D cameras and video cameras help ensure product consistency, while 3D systems enable precise measurement and inspection in hazardous environments. Employees in some industries may perceive these systems as a threat to their jobs due to the potential for automation.

- However, the benefits of machine vision systems extend beyond increased productivity and decreased machine downtime. They also facilitate the implementation of advanced AI algorithms, such as machine learning, for predictive maintenance and process optimization. Consumer Electronics, Medical and Pharmaceuticals, and other sectors are adopting these systems to maintain high-quality standards and improve yield. Frame Grabbers, Vision Systems, PC-based, and Vision sensors are essential hardware components, while communication systems and X-ray scanners serve specific applications. The integration of these systems with standard operating systems, interface protocols, and smart cameras allows for seamless communication between various components. The Advanced Manufacturing Partnership and the application of Artificial Intelligence and Machine Learning Algorithms are driving the evolution of machine vision systems.Companies are investing in these technologies to improve their manufacturing processes and maintain a competitive edge.

Exclusive Customer Landscape

The 2d and 3d machine vision systems market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the 2d and 3d machine vision systems market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, 2d and 3d machine vision systems market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Acrovision Ltd. - Machine vision systems are available in both 2D and 3D configurations, catering to diverse industry applications. These systems encompass offerings such as Modular Concept, Modification, and OEM development.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Acrovision Ltd.

- Allied Vision Technologies GmbH

- Atlas Copco AB

- Balluff GmbH

- Basler AG

- Baumer Holding AG

- Canon Inc.

- Cognex Corp.

- EPIC Systems Group LLC

- HTE Technologies

- IDS Imaging Development Systems Gmbh

- Intel Corp.

- Keyence Corp.

- MATRIX VISION GmbH

- MESH Automation Inc.

- OmniVision Technologies Inc.

- OMRON Corp.

- SICK AG

- Simac Techniek NV

- Teledyne DALSA Inc.

- TKH Group NV

- Tordivel AS

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Machine vision systems have become an integral part of modern industrial automation, enabling high-precision image processing and analysis in various sectors. These systems, which combine cameras, computer technology, and machine learning algorithms, facilitate automated inspection and process control in numerous applications. The market for machine vision systems encompasses both 2D and 3D systems, with the former offering plan view analysis and the latter providing additional depth perception. 2D machine vision systems, utilizing video cameras and standard operating systems, are widely used in industries such as consumer electronics, medical and pharmaceuticals, and food processing. These systems enable efficient material quality inspection, reducing machine downtime and increasing productivity.

3D machine vision systems, on the other hand, offer advanced capabilities, including the ability to analyze complex shapes and surfaces in three dimensions. These systems are particularly valuable in industries with intricate production processes, such as automotive manufacturing and aerospace. They are also essential in hazardous environments, where human intervention is undesirable or impossible. Machine vision systems have revolutionized the way industries handle high-speed production lines, enabling real-time process control and ensuring consistent product quality. In the chocolate inspection industry, for instance, these systems are used to monitor the production process, ensuring that each chocolate bar meets the desired specifications.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms in machine vision systems has further enhanced their capabilities. These intelligent systems can learn from data and adapt to new situations, improving quality and yield while reducing human intervention. Hardware components, such as frame grabbers, vision sensors, and communication systems, play a crucial role in the functionality of machine vision systems. These components facilitate the transfer and processing of image data, enabling seamless integration with other industrial systems. In the realm of computer technology, machine vision systems have evolved from simple image processing systems to sophisticated AI-driven solutions.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

138 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 10.03% |

|

Market growth 2024-2028 |

USD 8260.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

8.88 |

|

Key countries |

China, US, Japan, Germany, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this 2D And 3D Machine Vision Systems Market Research and Growth Report?

- CAGR of the 2D And 3D Machine Vision Systems industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the 2d and 3d machine vision systems market growth of industry companies

We can help! Our analysts can customize this 2d and 3d machine vision systems market research report to meet your requirements.