Elastomeric Coatings Market Size 2024-2028

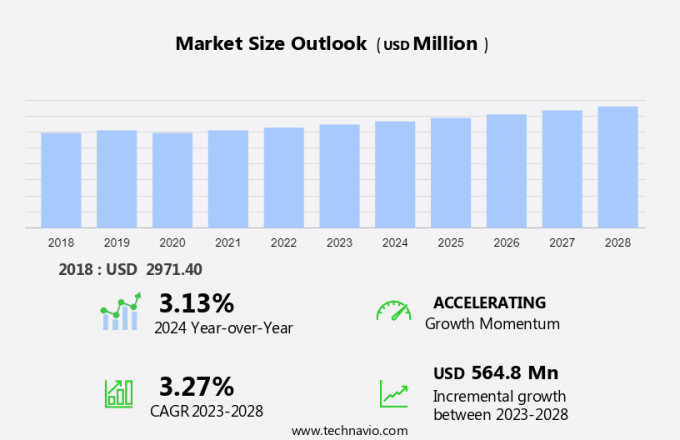

The elastomeric coatings market size is forecast to increase by USD 564.8 million at a CAGR of 3.27% between 2023 and 2028. The market is experiencing significant growth, driven by the increasing consumption of thermoplastic elastomer coatings in the automotive industry due to their superior properties such as durability, flexibility, and resistance to extreme temperatures. In the automotive sector, these coatings are extensively used for coating automotive plastic components, including small furniture, doors, and wood composites. Additionally, the burgeoning construction industry's demand for elastomeric coatings to enhance the durability and waterproofing of buildings is another growth factor. However, the market faces challenges due to the volatility in prices of raw materials, particularly oil and natural gas, which are key ingredients in the production of elastomeric coatings. Despite these challenges, the market is expected to continue its growth trajectory, fueled by the increasing demand for high-performance coatings in various end-use industries.

Market Analysis

Elastomeric coatings are a type of protective coating that provides flexibility and durability to various surfaces. These coatings are primarily used in building and construction applications for wall coatings and roof coatings. The key types of elastomeric coatings include Butyl, Polyurethane, Silicone, Acrylic, Polysulfide, Vinyl, Water Borne, and Solvent Borne. Elastomeric coatings offer excellent resistance to weathering, UV radiation, and heat absorption, making them ideal for energy-efficient options in construction. They reflect light and reduce the amount of heat absorbed by buildings, contributing to sustainable building methods. The market for elastomeric coatings is driven by the increasing demand for eco-friendly and sustainable building methods.

Additionally, waterborne production methods are gaining popularity due to their lower volatile organic compound (VOC) emissions. However, the use of hazardous chemicals in the production of certain types of elastomeric coatings, such as Polysulfide and some types of Silicone, is a concern. Bios-based elastomers are emerging as a viable alternative to traditional elastomeric coatings, offering similar performance with reduced environmental impact. The automotive industry also utilizes elastomeric coatings for interior applications as protective barriers against wear and tear. The market for elastomeric coatings is expected to grow due to the increasing demand for energy-efficient and sustainable building methods, as well as the need for durable and protective coatings in various industries.

Market Segmentation

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- Silicone

- Acrylic

- Urethane

- Geography

- APAC

- China

- India

- Japan

- Europe

- Germany

- North America

- US

- South America

- Middle East and Africa

- APAC

By Type Insights

The silicone segment is estimated to witness significant growth during the forecast period. Elastomeric coatings, including Butyl, Polyurethane, Silicone, Acrylic, Polysulfide, Vinyl, and various other types, serve as protective barriers for various applications such as wall coatings, roof coatings, and floor coatings. These coatings offer resistance to weathering, UV radiation, and heat absorption, making them essential for both interior and exterior walls of buildings, particularly in the construction sector. Water-borne production methods have gained popularity due to their eco-friendly and sustainable building methods, as opposed to solvent-borne coatings with high volatile organic compound emissions. Acrylic latex paints and silicone coatings are commonly used for interior walls, while butyl and polysulfide coatings are preferred for roofing applications.

Additionally, energy-efficient options like water-borne, cool roof coatings reflecting qualities are increasingly adopted to meet energy efficiency standards and certifications. These coatings offer resistance to extreme temperatures and climate change, making them suitable for concrete structures and automotive interior coatings. Bios-based elastomers are also emerging as a viable alternative to traditional elastomeric coatings, contributing to the market's growth.

Get a glance at the market share of various segments Request Free Sample

The silicone segment was valued at USD 2.17 billion in 2018 and showed a gradual increase during the forecast period.

Regional Insights

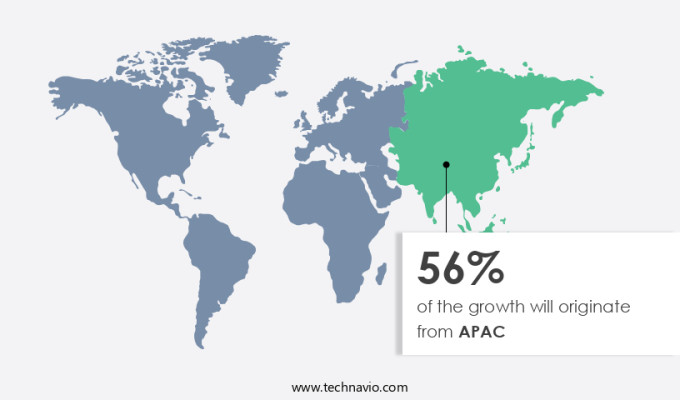

APAC is estimated to contribute 56% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

Elastomeric coatings, including Butyl, Polyurethane, Silicone, Acrylic, Polysulfide, Vinyl, and various other types, serve as protective barriers for various applications such as wall coatings, roof coatings, and floor coatings. These coatings offer resistance to weathering, UV radiation, and extreme temperatures, making them ideal for both interior and exterior use in buildings and construction. Water-borne production methods have gained popularity in recent years due to their eco-friendly and sustainable building methods, reducing the use of volatile organic compounds. Acrylic latex paints and water-based coatings are commonly used for interior walls, while silicone, polyurethane, and polysulfide coatings are preferred for exterior walls and concrete structures due to their superior weather resistance and reflecting qualities.

In addition, cool roof coatings, which reflect sunlight and absorb less heat, are energy-efficient options for buildings, contributing to energy efficiency standards and certifications. Bios-based elastomers are emerging as a sustainable alternative to traditional elastomeric coatings. These coatings offer the same protective qualities as their traditional counterparts but have a lower carbon footprint and are more environmentally friendly. Wall and roof coatings play a crucial role in the construction sector, providing resistance to weathering, UV radiation, and heat absorption, contributing to energy efficiency and climate change mitigation efforts.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Market Driver

The increasing consumption of thermoplastic elastomer coatings in automotive industry is the key driver of the market. Elastomeric coatings, which include thermoplastic elastomers such as acrylic, ethylene-propylene rubber, and polyurethane, are gaining popularity in various industries due to their superior durability and flexibility. The expansion of the automotive industry globally, driven by increasing sales in countries like China and India, is expected to fuel the demand for elastomeric coatings. For instance, the Chinese government aims to increase automobile sales to 35 million units by 2025, while the Indian automotive sector is expected to attract USD8-USD10 billion in investments by the end of 2023.

Additionally, besides the automotive industry, elastomeric coatings are also used in construction applications, including concrete, metal, and roofing materials, to enhance durability and protect against UV degradation and water intrusion. These coatings are also used in seals and gaskets, as well as in interior wood applications, such as furniture and doors. Silicone formulations, which are a type of elastomeric coating, are preferred for their reflective properties and low VOC content, making them ideal for indoor air quality considerations. Overall, the growing demand for elastomeric coatings in various industries is expected to drive market growth during the forecast period.

Market Trends

The burgeoning construction industry is the upcoming trend in the market. Elastomeric coatings, derived from materials such as acrylic, polyurethane, polysulfide rubber, silicone, and epoxy, are extensively utilized in various applications within the construction industry. These coatings offer significant advantages, including superior resistance to abrasion, chemicals, moisture, and temperature fluctuations. The burgeoning building and construction sector globally is fueling the demand for elastomeric coatings due to their durability and compatibility with diverse substrates, including concrete, metal, and roofing materials. Notable applications include interior wood for furniture, doors, and wood composites, as well as exterior uses for automotive components and plastic wood. Elastomeric coatings are also essential for seals and gaskets in various industries, where resistance to UV degradation and water intrusion is critical.

Additionally, construction practices necessitate elastomeric coatings to meet stringent substrate requirements and ensure indoor air quality, reflective properties, and compliance with regulations concerning volatile organic compounds (VOC). Some significant ongoing construction projects, such as Intel's Chandler Campus Expansion with a USD2 billion investment, will contribute to the market growth during the forecast period.

Market Challenge

The volatility in prices of raw materials is a key challenge affecting the market growth. Elastomeric coatings, including types such as acrylic and polyurethane, are derived primarily from crude oil and function as waterproof coatings. The volatility of global crude oil prices consequently impacts the pricing of elastomeric coatings, thereby hindering market expansion. In Q2 2020, global crude oil demand decreased by 2.5 million barrels per day (mb/d) due to the widespread lockdowns enforced worldwide as a response to the COVID-19 pandemic. This decline resulted in a reduction of approximately 90,000 barrels a day in comparison to the previous quarter.

Furthermore, according to BP's statistics, oil prices fell to USD64. Elastomeric coatings are employed in various sectors, including powder coatings, high solids coatings, two component systems, wood coatings for interior wood, small furniture, doors, wood composites, plastic wood, automotive components, furniture, construction, and roofing materials. Their durability makes them suitable for seals and gaskets, as well as for combating UV degradation and water intrusion. Silicone coatings, a type of elastomeric coating, are utilized in formulations for indoor air quality and reflective properties. However, the potential hazardous chemicals used in their manufacturing process necessitates careful consideration of substrate requirements, such as concrete, metal, and other materials, in construction practices.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

BASF SE: The company offers elastomeric coatings that provide a superior way for builders to reduce the amount of heat that is typically absorbed by traditional asphalt roofs, under the brand name of BASF.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- 3M Co.

- Acry tech Coatings Inc.

- Asian Paints Ltd.

- Choksey Chemicals Pvt. Ltd.

- Cloverdale Paint Inc.

- Dow Inc.

- DuluxGroup Ltd.

- DURABUILD

- Henry Co.

- Jotun AS

- Kamsons Chemicals Pvt. Ltd.

- LATICRETE International Inc.

- Masco Corp.

- Master Builders Solutions Deutschland GmbH

- Nippon Paint India Pvt. Ltd.

- PDI Roof Coatings

- PPG Industries Inc.

- Progressive Painting Inc.

- Sika AG

- The Sherwin Williams Co.

- Univar Solutions Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Elastomeric coatings are a type of protective coating that provides flexibility and resistance to various environmental conditions. These coatings are primarily used in building and construction applications, including wall coatings and roof coatings, for protective barriers against weathering, UV radiation, and heat absorption. The market includes various types such as Butyl, Polyurethane, Silicone, Acrylic, Polysulfide, Vinyl, and others. Elastomeric coatings are available in two main production methods: water borne and solvent borne. Water-borne elastomeric coatings are eco-friendly and sustainable building methods, as they emit fewer volatile organic compounds (VOCs) compared to solvent-borne coatings. The market for elastomeric coatings is driven by the construction sector's growing demand for energy-efficient options and certifications.

In conclusion, elastomeric coatings offer resistance to extreme temperatures and climate change, making them ideal for use on interior walls and exterior walls of buildings. They also have reflecting qualities, which make them popular for cool roof coating applications. New trends in the market include the use of bios-based elastomers and waterborne production methods to reduce the environmental impact of these coatings. Energy efficiency standards and certifications are also driving the demand for elastomeric coatings in various applications, including automotive interior coatings and protective barriers for concrete structures.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

141 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.27% |

|

Market growth 2024-2028 |

USD 564.8 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

3.13 |

|

Regional analysis |

APAC, Europe, North America, South America, and Middle East and Africa |

|

Performing market contribution |

APAC at 56% |

|

Key countries |

China, US, Japan, Germany, and India |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

3M Co., Acry tech Coatings Inc., Asian Paints Ltd., BASF SE, Choksey Chemicals Pvt. Ltd., Cloverdale Paint Inc., Dow Inc., DuluxGroup Ltd., DURABUILD, Henry Co., Jotun AS, Kamsons Chemicals Pvt. Ltd., LATICRETE International Inc., Masco Corp., Master Builders Solutions Deutschland GmbH, Nippon Paint India Pvt. Ltd., PDI Roof Coatings, PPG Industries Inc., Progressive Painting Inc., Sika AG, The Sherwin Williams Co., and Univar Solutions Inc. |

|

Market dynamics |

Parent market analysis, market growth inducers and obstacles, market forecast, fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, market condition analysis for the forecast period |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch