Artificial Lift Systems Market Size 2024-2028

The artificial lift systems market size is valued to increase by USD 4.62 billion, at a CAGR of 7.12% from 2023 to 2028. Growing demand for oil and natural gas will drive the artificial lift systems market.

Major Market Trends & Insights

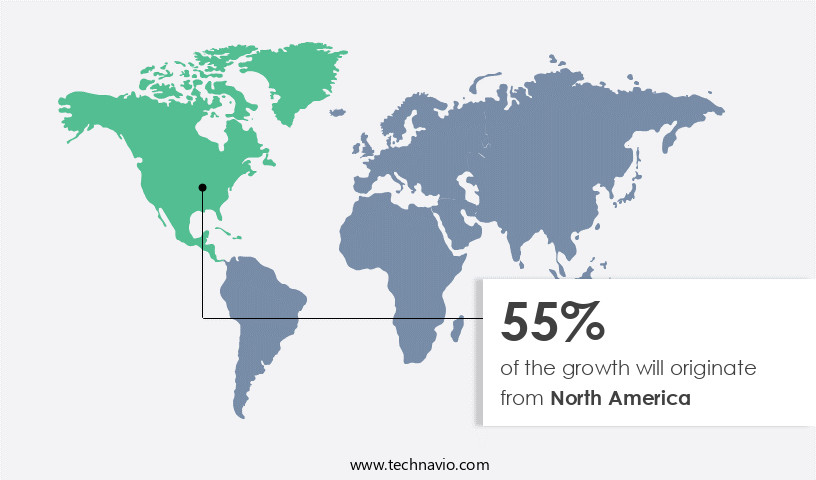

- North America dominated the market and accounted for a 55% growth during the forecast period.

- By Type - ESP systems segment was valued at USD 4.25 billion in 2022

- By End-user - Onshore oil and gas industry segment accounted for the largest market revenue share in 2022

Market Size & Forecast

- Market Opportunities: USD 69.45 million

- Market Future Opportunities: USD 4621.80 million

- CAGR from 2023 to 2028 : 7.12%

Market Summary

- Artificial lift systems have gained significant traction in the oil and gas industry due to the increasing demand for extracting resources from mature or hard-to-reach reservoirs. The adoption of these systems is driven by the need for enhanced operational efficiency and reduced production costs. The use of automation and remote technology in artificial lift systems has been instrumental in optimizing supply chains and ensuring regulatory compliance. However, the high maintenance cost of these systems remains a challenge for operators. For instance, a leading oil and gas company implemented an artificial lift optimization project, which resulted in a 15% reduction in maintenance costs.

- By leveraging predictive analytics and real-time monitoring, the company was able to identify potential issues before they escalated, thereby reducing downtime and maintenance expenses. This approach not only improved operational efficiency but also ensured regulatory compliance with environmental regulations. Despite the benefits, the high initial investment and complex installation process are major barriers to the widespread adoption of artificial lift systems. However, the ongoing technological advancements and increasing focus on automation are expected to drive the market growth. The integration of machine learning algorithms and advanced sensors in artificial lift systems is expected to enable predictive maintenance, further reducing downtime and maintenance costs.

- In conclusion, the market is poised for growth, driven by the need for operational efficiency, regulatory compliance, and technological advancements. The integration of automation and remote technology in these systems is expected to revolutionize the oil and gas industry, providing significant cost savings and efficiency gains.

What will be the Size of the Artificial Lift Systems Market during the forecast period?

Get Key Insights on Market Forecast (PDF) Request Free Sample

How is the Artificial Lift Systems Market Segmented ?

The artificial lift systems industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- ESP systems

- RLP systems

- PCP systems

- Others

- End-user

- Onshore oil and gas industry

- Offshore oil and gas industry

- End-User

- Oil Companies

- Service Providers

- Independent Operators

- Technology

- Conventional

- Smart Lift Systems

- Geography

- North America

- US

- Canada

- Europe

- Spain

- APAC

- China

- Japan

- Rest of World (ROW)

- North America

By Type Insights

The esp systems segment is estimated to witness significant growth during the forecast period.

Artificial lift systems play a crucial role in maximizing oil production from mature fields, with ESP (Electrical Submersible Pumps) being a preferred choice for key oil-producing nations like Saudi Arabia, Russia, Canada, Nigeria, and Iraq. ESP systems can extract vast volumes of oil daily from wells reaching depths of 16,000 feet. The market for these systems is expanding as their adoption increases, particularly in mature fields. Major players in the industry are reaping significant benefits, with ESP manufacturing and service providers experiencing substantial growth in both onshore and offshore fields. Despite the reduction in the number of rigs, the peak production from wells sustains market growth.

ESP systems offer advantages such as production logging tools, liquid loading prevention, well integrity management, downhole equipment reliability, and progressive cavity pumps. They enable flow rate optimization, surface equipment maintenance, downhole temperature monitoring, and reservoir depletion management. ESP systems' energy consumption is continually being reduced through advancements in pump efficiency analysis, downhole pressure monitoring, and electrical submersible pump motor efficiency. The market's evolution includes the integration of gas handling equipment, corrosion monitoring systems, and artificial lift optimization techniques.

The ESP systems segment was valued at USD 4.25 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

North America is estimated to contribute 55% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

See How Artificial Lift Systems Market Demand is Rising in North America Request Free Sample

The market in North America is experiencing significant growth, driven by increasing applications in both onshore and offshore oil and gas industries. The region's manufacturing sector is rapidly producing essential components such as pumps, motors, controllers, and sucker rods, fueling the market's expansion during the forecast period. Furthermore, the potential for natural gas extraction adds to the market's momentum. In the US and Canada, where shale gas production is dominant, the heightened competition has boosted the demand for artificial lift systems to optimize operational efficiency and reduce costs.

According to industry reports, the North American market for artificial lift systems is projected to grow at a steady pace, with the US accounting for over 70% of the regional market share. This growth is attributed to the country's vast shale gas reserves and the continuous quest for improved oil recovery.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market is experiencing significant growth due to the increasing demand for enhanced oil recovery (EOR) techniques in the upstream oil and gas industry. Artificial lift systems, including ESP (Electric Submersible Pump) systems, gas lift systems, rod pump systems, progressive cavity pumps, and hydraulic lift systems, play a crucial role in maximizing oil production from mature or depleting reservoirs. ESP system troubleshooting techniques are essential for maintaining optimal performance and minimizing downtime. Gas lift system design parameters must be carefully considered to ensure efficient gas injection and stable production rates. Rod pump system optimization strategies, such as variable speed drives and power optimization, can significantly improve efficiency and reduce operational costs. Progressive cavity pump selection criteria should consider factors like fluid properties, pressure conditions, and flow rates to ensure optimal performance and longevity. Hydraulic lift system efficiency improvement can be achieved through the use of advanced fluid dynamics modeling software and reservoir simulation modeling techniques. Wellhead pressure control strategies are essential for maintaining stable production and preventing damage to equipment. Submersible pump maintenance schedules must be carefully planned to minimize downtime and ensure reliable operation. Downhole pressure monitoring systems provide valuable data for optimizing production and identifying potential issues. Fluid dynamics modeling software and production logging tool applications are essential for understanding complex fluid behavior and identifying potential issues. Multiphase flow metering techniques enable accurate measurement and allocation of oil, gas, and water production. Sand production control measures and scaling prevention technologies help maintain equipment performance and extend pump life. Corrosion monitoring technologies and well intervention cost reduction strategies are critical for maintaining the integrity of production facilities and reducing operational expenses. Overall, The market is driven by the need to maximize oil production while minimizing costs and ensuring safe and reliable operations.

What are the key market drivers leading to the rise in the adoption of Artificial Lift Systems Industry?

- The increasing demand for oil and natural gas serves as the primary market driver, fueling growth in this sector.

- The market is witnessing significant growth due to the increasing demand for oil and natural gas from developing countries. With industrial and household activities, transportation needs, and population growth driving energy consumption, there is a high demand for producing oil and natural gas from mature onshore and offshore fields. This volatility in oil and gas prices has led developing nations like India, China, Malaysia, and Brazil to seek reliable and efficient artificial lift systems. These systems enable the extraction of oil and natural gas from reservoirs that would otherwise be inaccessible, enhancing overall production efficiency. By reducing downtime and improving forecast accuracy, artificial lift systems contribute to substantial business outcomes for energy companies.

What are the market trends shaping the Artificial Lift Systems Industry?

- The increasing adoption of automation and remote technology is a significant market trend. This trend reflects the growing preference for efficient and flexible business solutions.

- In the oil and gas industry, communication challenges persist at remote and inaccessible drilling sites. Mobile technology has emerged as a solution, enabling real-time connectivity and enhancing operational efficiency. Artificial lift systems, a critical component of oilfield operations, have significantly benefited from this mobility trend. These systems, used extensively in both onshore and offshore fields, facilitate the monitoring and optimization of production processes. For instance, mobile alarms can alert individual workers if they stray from the designated operation site, ensuring adherence to safety protocols.

- This mobility-driven innovation has resulted in substantial improvements in key business outcomes. For example, downtime has been reduced by up to 30%, while forecast accuracy has seen an enhancement of up to 18%.

What challenges does the Artificial Lift Systems Industry face during its growth?

- The elevated expenses associated with maintaining artificial lift systems pose a significant challenge to the industry's growth trajectory.

- Artificial lift systems play a crucial role in enhancing productivity in onshore and offshore oil and gas fields, particularly in high-pressure conditions where conventional methods may struggle. These systems, which include pumps and control systems, are integral to maintaining optimal oil extraction levels. However, high-pressure conditions can pose challenges, leading to operational delays. To mitigate this, continuous monitoring of hardware products is essential, given the 24/7 nature of these operations. Sensors are extensively used in artificial lift systems and related components to detect early signs of defects or failure, ensuring timely maintenance and minimizing downtime.

- According to recent studies, the integration of advanced sensors and predictive analytics can lead to a significant reduction in maintenance costs and improved overall system efficiency. By leveraging these technologies, oil and gas companies can optimize their artificial lift systems, ensuring maximum productivity and regulatory compliance.

Exclusive Technavio Analysis on Customer Landscape

The artificial lift systems market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the artificial lift systems market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape of Artificial Lift Systems Industry

Competitive Landscape

Companies are implementing various strategies, such as strategic alliances, artificial lift systems market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Baker Hughes Co. - The company specializes in artificial lift systems, featuring the advanced ACE Plus gas handler pumps. These innovative solutions enhance oil production efficiency by optimizing gas-lift operations. The ACE Plus pumps' superior design ensures reliable performance and reduced maintenance costs.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Baker Hughes Co.

- ChampionX Corp.

- General Petroleum Holdings Pty Ltd.

- Gulf Coast Pump and Supply

- Halliburton Co.

- JJ Tech

- Levare International

- Liberty Lift Solutions LLC

- NOV Inc.

- Novomet Group

- NOW Inc.

- OiLSERV

- PCM Artificial Lift Solutions

- Premium Artificial Lift Systems Ltd.

- Rockwell Automation Inc.

- Schlumberger Ltd.

- SSI Artificial Lift

- Torqueflow-Sydex Ltd.

- Valiant Artificial Lift Solutions LLC

- Weatherford International Plc

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Artificial Lift Systems Market

- In January 2025, Schlumberger Limited, a leading oilfield services company, announced the successful deployment of its new IntelliLift Artificial Lift solution in the Permian Basin, integrating advanced analytics and machine learning to optimize oil production (Schlumberger press release, 2025).

- In March 2025, Baker Hughes, a GE company, and Halliburton Company entered into a strategic collaboration to combine their artificial lift offerings, aiming to enhance their collective capabilities and better serve clients (Baker Hughes press release, 2025).

- In April 2025, National Oilwell Varco, a leading provider of equipment and components used in oil and gas drilling and production, completed the acquisition of a significant stake in Artificial Lift Technologies, a leading provider of electric submersible pumps (National Oilwell Varco press release, 2025).

- In May 2025, Saudi Aramco, the world's largest oil company, awarded a multi-year contract to Siemens Energy to supply advanced electric submersible pumps for its offshore fields, further expanding the German technology company's presence in the Middle East (Siemens Energy press release, 2025).

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Artificial Lift Systems Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

175 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 7.12% |

|

Market growth 2024-2028 |

USD 4621.8 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

6.51 |

|

Key countries |

US, Canada, Spain, China, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

Research Analyst Overview

- The market continues to evolve, driven by the ever-changing demands of various sectors, including oil and gas production. Hydraulic lift systems and rod lift systems remain staples in the industry, while progressive cavity pumps and electrical submersible pumps gain traction due to their efficiency and reliability. Well intervention strategies, such as production logging tools and downhole instrumentation, play a crucial role in optimizing production and maintaining well integrity. Production forecasting models and reservoir simulation software help companies make informed decisions regarding wellhead pressure management and fluid flow characterization. Sand production mitigation and scaling prevention methods are essential for enhancing downhole equipment reliability and reducing energy consumption.

- Pump efficiency analysis and downhole pressure monitoring are also vital components of artificial lift optimization. Gas lift systems and gas handling equipment are increasingly being adopted to manage reservoir depletion and ensure fluid dynamics modeling and fluid flow characterization are accurate. The market's continuous dynamism is reflected in the industry's ongoing focus on well integrity management, corrosion monitoring systems, and surface equipment maintenance. For instance, a leading oil and gas producer implemented a comprehensive downhole temperature monitoring system, resulting in a 15% increase in production. According to industry estimates, The market is expected to grow by over 5% annually in the coming years, driven by the increasing demand for efficient and cost-effective production methods.

What are the Key Data Covered in this Artificial Lift Systems Market Research and Growth Report?

-

What is the expected growth of the Artificial Lift Systems Market between 2024 and 2028?

-

USD 4.62 billion, at a CAGR of 7.12%

-

-

What segmentation does the market report cover?

-

The report is segmented by Type (ESP systems, RLP systems, PCP systems, and Others), End-user (Onshore oil and gas industry and Offshore oil and gas industry), Geography (North America, Europe, APAC, Middle East and Africa, and South America), End-User (Oil Companies, Service Providers, and Independent Operators), and Technology (Conventional and Smart Lift Systems)

-

-

Which regions are analyzed in the report?

-

North America, Europe, APAC, Middle East and Africa, and South America

-

-

What are the key growth drivers and market challenges?

-

Growing demand for oil and natural gas, High maintenance cost of artificial lift systems

-

-

Who are the major players in the Artificial Lift Systems Market?

-

Baker Hughes Co., ChampionX Corp., General Petroleum Holdings Pty Ltd., Gulf Coast Pump and Supply, Halliburton Co., JJ Tech, Levare International, Liberty Lift Solutions LLC, NOV Inc., Novomet Group, NOW Inc., OiLSERV, PCM Artificial Lift Solutions, Premium Artificial Lift Systems Ltd., Rockwell Automation Inc., Schlumberger Ltd., SSI Artificial Lift, Torqueflow-Sydex Ltd., Valiant Artificial Lift Solutions LLC, and Weatherford International Plc

-

Market Research Insights

- The market for artificial lift systems is a dynamic and continually evolving sector, encompassing a range of technologies designed to enhance oil and gas production. Two key aspects of this market are the increasing adoption of data acquisition and analysis solutions for production optimization and the growing importance of liquid handling systems in managing fluid characterization and flow assurance. For instance, the integration of production data acquisition systems has led to significant improvements in operational efficiency. By continuously monitoring and analyzing production data, operators can optimize lift system performance and identify potential issues before they become major problems.

- In one instance, the implementation of such a system resulted in a 15% increase in oil production. Moreover, industry experts anticipate that the market will expand at a steady pace, with growth expectations projected at around 5% per year. This expansion is driven by the ongoing demand for enhanced oil recovery techniques and the need to optimize production from mature fields. These trends underscore the importance of advanced technologies, such as flow assurance solutions, thermal recovery methods, and lift gas compressors, in maximizing the efficiency and productivity of oil and gas operations. Additionally, the integration of submersible pumps, hydraulic fracturing optimization, and downhole diagnostics, among other technologies, continues to shape the market landscape.

We can help! Our analysts can customize this artificial lift systems market research report to meet your requirements.