Flexible Shaft Couplings Market Size 2025-2029

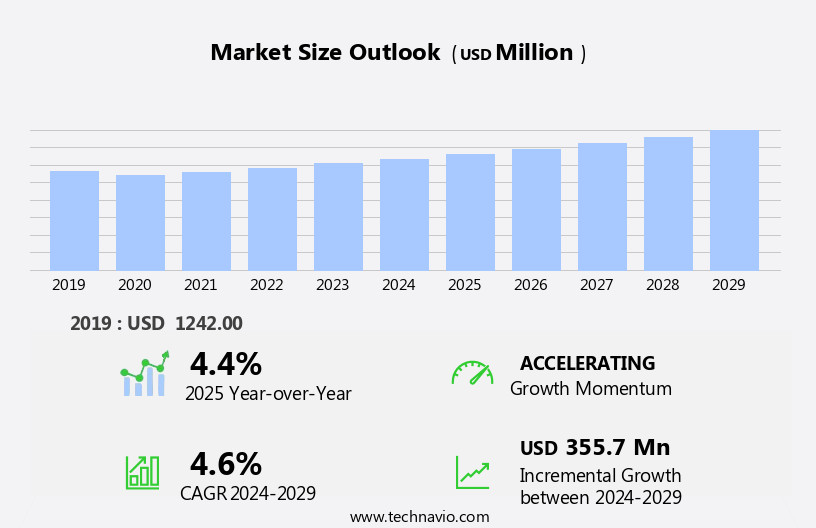

The flexible shaft couplings market size is forecast to increase by USD 355.7 million at a CAGR of 4.6% between 2024 and 2029.

- The market is witnessing significant growth due to the increasing demand for these components in high-speed and high-torque applications, particularly in the power generation and industrial sectors. Prime movers such as pumps, compressors, and generators in the oil and gas industry are major consumers of flexible shaft couplings, as they require strong and reliable connections to transmit power efficiently. The growing construction sector is also driving demand for flexible shaft couplings in the region due to the increasing use of automation and robotics in the industry. Additionally, the rise in crude oil and natural gas production and the subsequent increase in pipeline activity are expected to boost market growth.

- However, the improper selection of couplings for specific applications can lead to operational inefficiencies and potential safety hazards, which may hinder market growth. The market is segmented into materials such as steel, plastic, rubber, and sensors, catering to various industries and applications.

What will be the Size of the Flexible Shaft Couplings Market During the Forecast Period?

- The market encompasses the production and distribution of components that connect and transmit power between misaligned or distant shafts. This market caters to various industries, including mining and manufacturing, where the need for flexible and strong power transmission solutions is paramount. Technological advancements have led to the development of innovative flexible shaft couplings capable of handling extreme torque and high speeds, addressing the demands of oil and gas and steel industries. These couplings enable same line end-to-end power transmission, minimizing axial movement and reducing shaft misalignment, thereby ensuring efficient torque transmission and minimizing vibrations. The market's prognosis period reflects steady growth, driven by the increasing focus on improving operational efficiency and productivity across industries.

How is this Flexible Shaft Couplings Industry segmented and which is the largest segment?

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Product

- Elastomeric couplings

- Mechanical couplings

- Disc couplings and others

- Application

- Oil and gas industry

- Power plants

- Mining and metal industry

- Others

- End-user

- Tire manufacturing

- Steel industry

- Power and energy

- Automotive industry

- Others

- Type

- Compensating

- Stepper and servo motors

- Fans and blowers

- Geography

- APAC

- China

- India

- Japan

- Europe

- Germany

- UK

- France

- Italy

- North America

- Canada

- Mexico

- US

- South America

- Middle East and Africa

- APAC

By Product Insights

- The elastomeric couplings segment is estimated to witness significant growth during the forecast period.

Flexible shaft couplings, specifically elastomeric couplings, are non-lubricated transmission systems used for power transmission between shafts. Made primarily of elastomer materials like rubber, plastic, and urethane, they offer several advantages in various industries. Eliminating the need for lubrication and maintenance services, these couplings ensure ease of installation and visual inspection. The mining industry, manufacturing sector, steel industry, and others benefit significantly from their high torque capacity and resistance to axial movement, shaft misalignment, vibrations, and extreme torque transmission.

Technological advancements have led to the development of lightweight, smart technologies and sensor technologies, making maintenance-free couplings a preferred choice. The elastomeric coupling segment's growth is driven by its versatility and adaptability to various applications in aerospace, manufacturing, marine, energy, robotics, and other industries. Material selection and design innovation continue to play a crucial role in enhancing their performance and efficiency.

Get a glance at the market report of share of various segments Request Free Sample

The Elastomeric couplings segment was valued at USD 598.50 million in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

- APAC is estimated to contribute 59% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in APAC is anticipated to witness significant growth during the forecast period, with China, Japan, India, and South Korea leading the charge. The expansion of industries such as food and beverages and oil refining is driving market growth in the region. In China and India, the increasing automobile penetration is fueling the demand for crude oil refining, leading to new capacity additions. Additionally, China's investment in natural gas pipeline construction for import and distribution is increasing the demand for flexible shaft couplings in the energy sector. Technological advancements in flexible shaft couplings, including those that address axial movement, shaft misalignment, extreme torque transmission, and vibration reduction, are also contributing to market growth.

The manufacturing, mining, aerospace, marine, energy, robotics, and other industries are major application areas for flexible shaft couplings, with material selection and design innovation being key factors in their selection. Maintenance-free couplings and smart technologies, including sensor technologies, are also gaining popularity in various industries due to their benefits in terms of efficiency and reliability.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Flexible Shaft Couplings Industry?

Increased demand for flexible shaft couplings from high speed and high torque applications is the key driver of the market.

- Flexible shaft couplings are essential components in various industries, including oil and gas, mining, and manufacturing, due to their ability to transmit high torque and accommodate shaft misalignment. These couplings are particularly beneficial in high-speed applications, such as those found in centrifugal pumps, as they provide torsional rigidity and absorb shock and vibration. The flexible components, like elastomeric sleeves and metal winding, enable misalignment, but the gear teeth curve influences the misalignment capacity. The mining industry relies on flexible shaft couplings for their durability and ability to withstand extreme torque transmission. In the manufacturing industry, these couplings are utilized in heavy machinery to ensure smooth operation and reduce downtime.

- The steel industry also benefits from flexible shaft couplings due to their high torque capacity and ability to handle high speeds. Technological advancements have led to the development of smart technologies and sensor technologies, resulting in maintenance-free couplings that enhance system efficiency and reliability. Additionally, lightweight designs and design innovations have expanded the application engineering possibilities for flexible shaft couplings in sectors such as aerospace, marine, energy, robotics, and more.

What are the market trends shaping the Flexible Shaft Couplings Industry?

Increasing oil and gas pipeline activity is the upcoming market trend.

- The market experiences significant growth due to its extensive applications in various industries, particularly in the oil and gas sector. The expansion of oil terminals worldwide drives the demand for these couplings, as they are crucial components in gas turbines and efficient supply systems for midstream and downstream oil and gas activities. Oil terminals serve as storage centers for crude oil and petroleum products and facilitate oil and gas transportation, thereby strengthening the oil and gas supply chain. Despite price fluctuations in the oil and gas industry, the high consumption pattern of these products necessitates a strong pipeline infrastructure.

- Mining and manufacturing industries also contribute significantly to the market growth due to the technological advancements in these sectors. The mining industry requires flexible shaft couplings to transmit extreme torque and withstand heavy vibrations and misalignment. In the manufacturing industry, these couplings ensure maintenance-free operation and are employed in high torque and high-speed applications. Moreover, the steel industry, aerospace, marine, energy, robotics, and application engineering sectors also utilize flexible shaft couplings due to their lightweight, smart technologies, and sensor technologies. Material selection and design innovation play a vital role in enhancing the performance and efficiency of these couplings. The export conditions and competition from local manufacturers influence the market dynamics.

What challenges does the Flexible Shaft Couplings Industry face during its growth?

Improper selection of couplings for specific applications is a key challenge affecting the industry growth.

- Flexible shaft couplings are essential components in various industries, including oil and gas, mining, and manufacturing, for transmitting power between misaligned or axially moving shafts. These couplings mitigate shaft misalignment and absorb vibrations, enabling efficient torque transmission under extreme conditions. The mining industry, in particular, requires high-performance flexible shaft couplings due to the dynamics of heavy machinery and the prognosis period for maintenance. Flexible shaft couplings come in various types, such as bellow, elastomeric, chain, gear, disc, and diaphragm couplings, each designed for specific applications based on torque, speed, and environmental conditions. For instance, below couplings are suitable for high torque and low-speed applications, while elastomeric couplings are ideal for low-speed, high torque applications.

- Selecting the appropriate flexible shaft coupling is crucial to prevent coupling failure and ensure the equipment's optimal performance. Failure to choose the right coupling can result in significant efficiency losses. In the manufacturing industry, for example, misalignment and vibration can lead to downtime and increased maintenance costs. Technological advancements have led to innovations in flexible shaft couplings, such as lightweight, smart technologies, and sensor technologies, which offer maintenance-free operation and enhanced performance. Applications engineering and material selection play a significant role in designing flexible shaft couplings for various industries, including aerospace, marine, energy, robotics, and the steel industry.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

AB SKF: The company offers flexible shaft couplings with oil injection mounting which provides a high torque interference fit for plain, cylindrical shafts.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- AB SKF

- ABB Ltd.

- Altra Industrial Motion Corp.

- Chr. Mayr GmbH Co. KG

- DieQua Corp.

- EMBRAGATGES I DERIVATS S.A

- Flender GmbH

- Gates Industrial Corp. Plc

- GKN Automotive Ltd.

- JAKOB Antriebstechnik GmbH

- Nabeya Bi tech Kaisha

- Parker Hannifin Corp.

- Ramsey Products Corp.

- Regal Rexnord Corp.

- RINGFEDER POWER TRANSMISSION GMBH

- Siemens AG

- The Timken Co.

- Tsubakimoto Europe BV

- Voith GmbH and Co. KGaA

- Zero Max Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Flexible shaft couplings play a crucial role in transmitting power between rotating shafts in various industries, enabling smooth operation and minimizing the effects of misalignment and vibrations. These components are essential in applications where axial movement is unavoidable or where the shafts are not aligned perfectly. The flexible shaft coupling market is driven by the increasing demand for efficient power transmission in industries such as manufacturing, mining, oil and gas, and aerospace. Technological advancements have led to the development of high-performance couplings capable of transmitting extreme torque and operating at high speeds. One of the significant challenges in the flexible shaft coupling market is shaft misalignment, which can lead to vibrations and premature failure of the coupling.

Moreover, manufacturers have responded by designing couplings with advanced features such as self-aligning capabilities and sensor technologies to detect and mitigate misalignment issues. Another critical factor In the market is the need for maintenance-free couplings. In industries where downtime is costly, such as mining and manufacturing, there is a growing demand for couplings that can operate continuously without requiring frequent maintenance. This has led to the development of smart technologies that enable real-time monitoring and predictive maintenance. Material selection and design innovation are also key considerations In the flexible shaft coupling market. Manufacturers are using lightweight materials and advanced manufacturing techniques to produce couplings that are stronger, more durable, and more efficient.

Furthermore, this is particularly important in industries such as mining and steel, where the couplings are subjected to heavy loads and harsh operating conditions. The prognosis period for the flexible shaft coupling market is positive, with continued growth expected due to the increasing demand for efficient power transmission and the development of new technologies. Export conditions and competition from local manufacturers are also factors that will influence the market dynamics. In the manufacturing industry, flexible shaft couplings are used extensively in robotics applications, where precise power transmission is essential for accurate and efficient operation. In the energy sector, flexible shaft couplings are used in wind turbines and other renewable energy systems to transmit power from the generator to the electrical grid.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

250 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.6% |

|

Market growth 2025-2029 |

USD 355.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

4.4 |

|

Key countries |

China, US, Japan, UK, Canada, Germany, India, France, Italy, and Mexico |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.