Foundry Coke Market Size 2024-2028

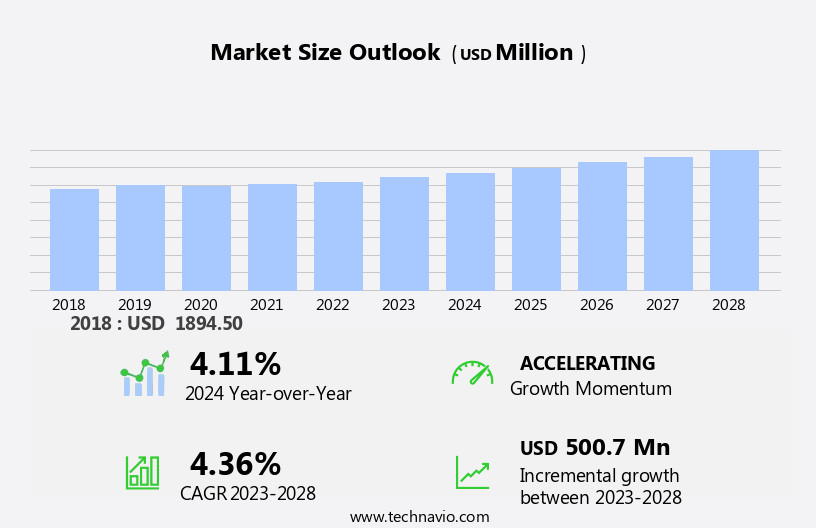

The foundry coke market size is forecast to increase by USD 500.7 million at a CAGR of 4.36% between 2023 and 2028.

- The market is experiencing significant growth due to the expanding steel industry and increasing demand for coke from emerging markets. This trend is expected to continue as steel production continues to rise, particularly in the Asia Pacific. However, the market is facing challenges from the volatility in raw material prices, which can impact the profitability of coke producers. To mitigate these challenges, market players are focusing on improving production efficiency and exploring alternative raw materials. The automobile industry's growth is a key growth generator for the market. The market is also witnessing the adoption of advanced technologies, such as automation and digitalization, to enhance operational efficiency and reduce costs. Overall, the market is poised for steady growth, driven by the demand from the steel industry and the adoption of innovative technologies.

What will be the Size of the Foundry Coke Market During the Forecast Period?

- Foundry coke, a vital by-product of the coal-based iron and steel industry, plays a significant role in the production of various metals such as iron, copper, lead, tin, and zinc. This article provides an insight into the dynamics of the market, focusing on its applications In the automobile sector and end-user industries. Foundry coke is primarily produced in furnaces, including cupolas and jumbo-ovens, through the by-product recovery process. The high heat value and compact structure of coke make it an ideal fuel for metal melting processes. Its extensive carbon content ensures efficient reduction of metal oxides, leading to the production of high-quality metals.

- The automobile sector is a significant consumer of coke, with its extensive use in the manufacturing of engine blocks, cylinder liners, and other critical components. Beyond the automobile sector, coke finds extensive applications in various end-user industries. Its use in the production of iron and other non-ferrous metals is noteworthy. The construction industry also utilizes coke as a fuel source in the production of various building materials. The market's growth is influenced by several factors. The extensive use of coke in the production of metals, particularly iron, makes it a crucial component in urbanization and construction activities.

- The increasing demand for infrastructure development and housing projects fuels the demand for foundry coke. The quality of foundry coke is a critical factor in its demand. The compact structure and high heat value of foundry coke make it an ideal fuel source. However, the issue of breakage during transportation and handling remains a challenge for the industry. The use of insulating materials, such as stone wool, can help mitigate this issue by reducing heat loss during transportation and ensuring the coke's stability. The coal output and coal imports significantly impact the market. The availability and cost of coal are essential factors in the production of coke.

- The coal industry's fluctuations can lead to volatility in the market. The market plays a crucial role In the metal industry, with significant applications in the automobile sector and various end-user industries. The market's growth is influenced by several factors, including urbanization, construction activities, and the quality of coke. The challenges of coke breakage and the impact of coal output and imports on the market are essential considerations for industry participants.

How is this Foundry Coke Industry segmented and which is the largest segment?

The foundry coke industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- Pig iron

- Copper

- Zinc

- Others

- Application

- Automotive parts casting

- Machinery casting

- Material treatment

- Geography

- APAC

- China

- Japan

- North America

- US

- Europe

- Germany

- Italy

- South America

- Middle East and Africa

- APAC

By Type Insights

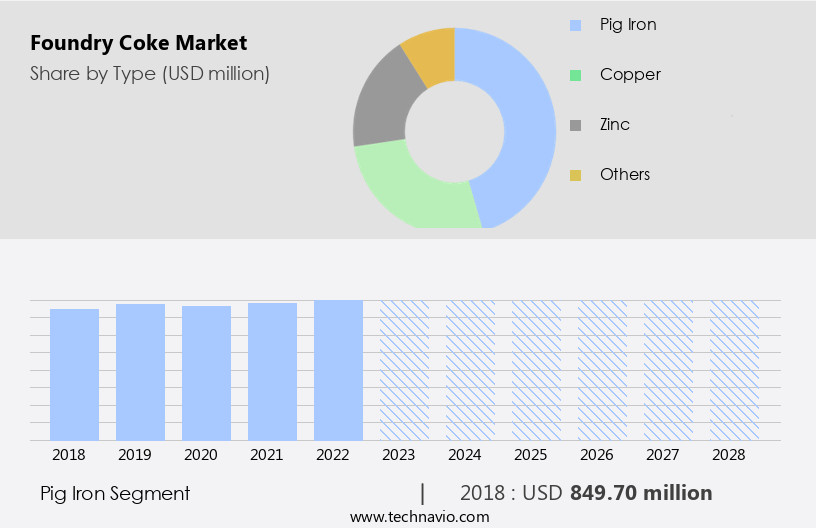

- The pig iron segment is estimated to witness significant growth during the forecast period.

Foundry coke is an essential component In the manufacturing processes of various industries, particularly In the production of steel, sintered metals, aluminum alloys, and magnesium alloys. In the steel industry, pig iron, which is an intermediate product In the iron and steel production process, is largely produced using coke. Pig iron is created through the smelting of iron ore in blast furnaces, where coke is utilized as both a fuel and a reducing agent. The coke generates the required heat and carbon for the smelting process, allowing iron ore to undergo necessary chemical reactions. Additionally, coke is used In the production of automotive parts casting and machinery casting.

Furthermore, it is employed in the application of ceramic and metallic coverings. The ash content of coke can vary depending on its source and production process, influencing its end-use applications. In summary, coke plays a significant role in the manufacturing of various industries, particularly In the production of pig iron for steel manufacturing. It provides the necessary heat and carbon for the smelting process, making it an indispensable resource.

Get a glance at the market report of share of various segments Request Free Sample

The Pig iron segment was valued at USD 849.70 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

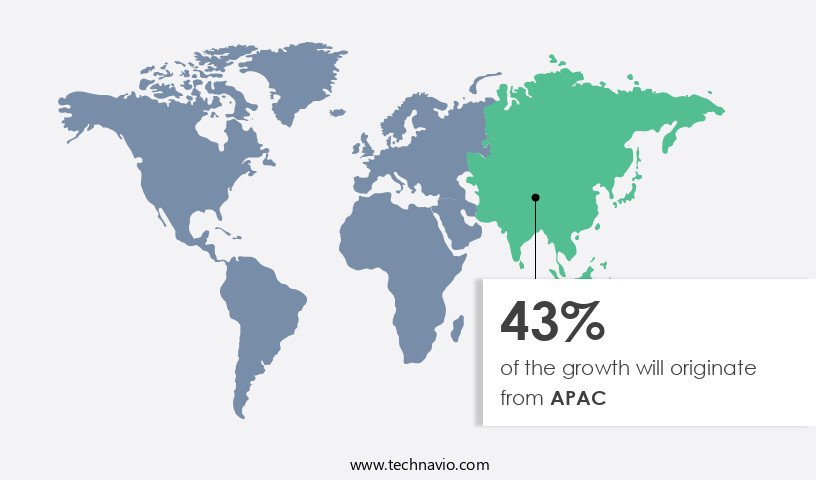

- APAC is estimated to contribute 43% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market In the Asia Pacific region is projected to experience substantial growth during the assessment period. This region is a significant consumer and manufacturer of Foundry Coke, primarily due to the presence of major steel-producing nations, burgeoning industrial development, and increasing demands from the automotive and construction industries. Key countries, including India, China, and Japan, are major contributors to the market in Asia Pacific. Among these, China holds a prominent position, being the largest producer and consumer of Foundry Coke In the region. The Chinese steel industry, which is the world's largest, heavily utilizes Foundry Coke for pig iron production.

The carbon content and heating value of Foundry Coke make it an essential fuel and carbon source for this process. This dependence on Foundry Coke significantly influences the global market dynamics.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Foundry Coke Industry?

Growing steel industry is the key driver of the market.

- The market is experiencing significant growth due to the expanding steel industry, which is a primary consumer of coke. Foundry coke plays a crucial role In the production of pig iron, an essential intermediate product in steel manufacturing. The construction sector, which is a significant end-user of steel, is driving the demand for coke. Urbanization, infrastructure development, and population growth worldwide lead to increased construction activities, resulting in a higher demand for steel and, consequently, coke. In the automotive sector, coke is used extensively In the production of automotive parts casting. The market participants in the coke industry include Walter Energy, SMS team, and various other producers.

- They utilize different types of coke ovens, such as jumbo-ovens and non-recovery coke ovens, to produce coke. The beehive process is commonly used In the production of coke, which results in a denser structure and lower ash content. The market is also influenced by the by-product recovery process, which allows for the production of sintered metals, aluminum alloys, magnesium alloys, and other valuable by-products. The market for these by-products is growing, leading to increased demand for coke. The market is further driven by the high heat value and extensive carbon content of coke, making it an ideal fuel source for various industries.

- The market is expected to grow during the assessment period, with major players focusing on strategic collaborations and process improvements to increase revenues. The market is also influenced by factors such as the carbon content, heating value, and metallurgical properties of the coke. The use of insulating materials, such as stone wool, In the coke furnace and cupola furnace, is also a significant trend In the market. Overall, the market is a critical component of various industries, including steel, automotive, and construction, and is expected to continue growing In the coming years.

What are the market trends shaping the Foundry Coke Industry?

Rising demand for foundry coke from emerging markets is the upcoming market trend.

- The market is witnessing significant growth due to the increasing demand from the automobile sector and end-user industries such as machinery casting and automotive parts casting. The automobile industry's requirement for cast iron and sintered metals, including aluminum alloys and magnesium alloys, is driving the demand for coke. The metallurgical process of producing these metals involves the use of coke as a fuel and carbon source. In the APAC region, countries like China and India are undergoing extensive urbanization and construction activities, leading to a wave in steel production. Steel is a primary consumer of coke, making it an essential ingredient In the region's industrial growth.

- The demand for coke is further boosted by the need for insulating materials In the metallurgical process. Insulating materials such as stone wool and metallic coverings require high heat value and compact structure, making coke an ideal choice. The market participants include Walter Energy, SMS team, and Pohang Steelworks, among others. The market is witnessing strategic collaborations and the adoption of advanced technologies such as the beehive process, which allows for denser structure, low ash content, and efficient furnace size. The by-product recovery process is also gaining popularity, allowing for the production of coke with extensive carbon content and improved carbon content and heating value.

- The market is expected to continue its growth trajectory during the assessment period. The market dynamics are influenced by factors such as urbanization, construction activities, and the need for high-quality coke with low ash content and compact structure. The market is also driven by the increasing demand for steel in various industries and the need for insulating materials In the metallurgical process.

What challenges does the Foundry Coke Industry face during its growth?

Volatility in raw material prices is a key challenge affecting the industry growth.

- The market is influenced by the volatility of coal prices, which serve as the primary raw material for coke production. Metallurgical coal, in particular, is essential for manufacturing coke. The price fluctuations of this fuel source significantly impact the production costs and profitability of coke manufacturers. The coal market's volatility is driven by various factors, including supply-demand imbalances and geopolitical influences. Unexpected coal production disruptions or trade disputes can lead to coal price increases, negatively affecting the coke industry. Additionally, changes in government policies can impact the availability and cost of coal. Foundry coke is a critical component In the cast iron and steel industries, particularly in the automobile sector and end-user sectors.

- It is used in various applications, such as automotive parts casting, machinery casting, and insulation. Foundry coke comes in various forms, including Bluestone Coke, Walter Coke, ERP Compliant Coke, and others. The market participants include key players like the SMS team, Pohang Steelworks, and Walter Energy. Foundry coke production processes include coke furnaces, cupola furnaces, jumbo-ovens, and beehive processes. The market's growth is driven by urbanization and construction activities, which increase the demand for cast iron and steel products. The market's future outlook is promising due to strategic collaborations, the by-product recovery process, and the extensive carbon content and high heat value of coke.

- However, the market faces challenges such as breakage, metal temperature, and the non-recovery coke ovens' denser structure and low ash content. The furnace size and process also impact the market's dynamics.

Exclusive Customer Landscape

The foundry coke market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the foundry coke market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, foundry coke market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ArcelorMittal SA

- China Coke Group Holding Co. Ltd.

- Drummond Co. Inc.

- GR RESOURCE LTD.

- HEBEI YUNAI NEW MATERIAL TECHNOLOGY CO. LTD.

- Hickman Williams and Co.

- Italiana Coke Srl

- Jiangsu surung High carbon Co. Ltd.

- Majufa Traders and Exporters

- Nippon Coke and Engineering Co. Ltd.

- OKK Koksovny a.s.

- Quimica del Nalon SA

- Richa Refractories

- RIZHAO HENGQIAO CARBON CO. LTD.

- Rizhao Yeneng New Energy Technology Co. Ltd

- Sesa Goa Iron Ore

- Shree Arihant Trade Links India Pvt Ltd.

- Siddhi Vinayak Impex

- Walbrzyskie Zaklady Koksownicze Victoria SA

- Zhongrong Xinda Group Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market is a significant segment of the global coal industry, primarily used as a fuel in foundries for the production of cast iron and other non-ferrous metals. The market is driven by the automobile sector and various end-user industries, including machinery manufacturing and construction. Cast iron is a crucial component in various industries, including automotive and machinery manufacturing. Foundry coke plays a vital role In the production of cast iron, as it is used as a fuel in cupolas and furnaces. The automobile sector is a significant consumer of cast iron, and the increasing demand for automobiles, especially in emerging economies, is driving the growth of the market.

Furnaces, such as cupolas and coke furnaces, are essential equipment in foundries. Coke produced in coke ovens, such as jumbo-ovens and non-recovery coke ovens, is used as a fuel In these furnaces. The beehive process is commonly used In the production of coke in coke ovens. The by-product recovery process is used to extract value-added products, such as tar and ammonia, from the coke oven gas. Insulating materials, such as stone wool, are used In the lining of furnaces to improve their efficiency and reduce heat loss. The use of insulating materials in furnaces is increasing due to the growing demand for energy-efficient and cost-effective production processes.

The coal output and coal imports play a significant role in the production of foundry coke. Hard coal is the primary raw material used in the production of coke. The carbon content and heating value of coal are essential factors that determine the quality of coke produced. The steel industry is another significant consumer of foundry coke. Sintered metals, aluminum alloys, magnesium alloys, and ceramic products are produced using pig iron, which is primarily produced using coke as a fuel. The increasing demand for these metals in various industries, including construction and automotive, is driving the growth of the market.

Market participants, such as Walter Energy and SMS Siemag, are investing In the development of ERP compliant coke and advanced coke-making technologies to reduce the ash content and improve the carbon source quality. The use of compact structure and denser coke in furnaces leads to increased efficiency and reduced fuel consumption. The growth of the market is driven by various factors, including urbanization, construction activities, and the increasing demand for cast iron and other non-ferrous metals in various industries. The market is expected to grow at a significant rate during the assessment period due to these factors. The market is a dynamic and competitive market, with various players operating in different regions.

Strategic collaborations and mergers and acquisitions are common In the market to expand the product portfolio and increase market share. The market is a significant segment of the global coal industry, driven by the automobile sector and various end-user industries. The market is expected to grow at a significant rate during the assessment period due to the increasing demand for cast iron and other non-ferrous metals and the growing focus on energy-efficient and cost-effective production processes.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

160 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.36% |

|

Market growth 2024-2028 |

USD 500.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.11 |

|

Key countries |

China, US, Germany, Japan, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Foundry Coke Market Research and Growth Report?

- CAGR of the Foundry Coke industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the foundry coke market growth of industry companies

We can help! Our analysts can customize this foundry coke market research report to meet your requirements.