Robotic Injection Molding Machine Market Size 2024-2028

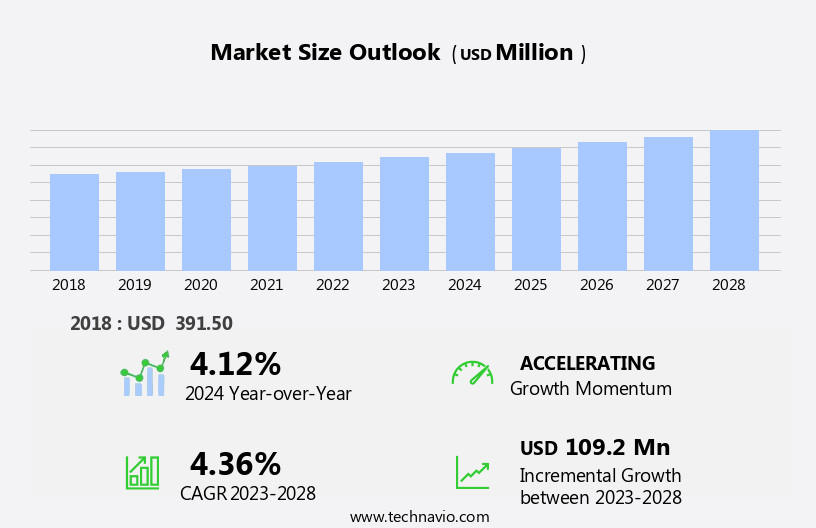

The robotic injection molding machine market size is forecast to increase by USD 109.2 million at a CAGR of 4.36% between 2023 and 2028.

- The market is experiencing significant growth due to the productivity improvements offered by these advanced systems. Robotic injection molding machines enable increased production rates, reduced cycle times, and enhanced product quality, making them an attractive investment for manufacturing industries. A key trend driving market growth is the integration of collaborative robots, or cobots, into the injection molding process. Cobots offer flexibility, ease of use, and cost-effectiveness, expanding the application scope of robotic injection molding machines. However, the high initial cost associated with these systems remains a significant challenge for market growth. Robotic injection molding machines require substantial capital investment for the purchase, installation, and maintenance of the equipment.

- Additionally, regulatory hurdles impact adoption, as manufacturers must comply with safety and environmental regulations when implementing these systems. Supply chain inconsistencies also temper growth potential, as the availability and reliability of raw materials and components can impact production schedules and efficiency. Companies seeking to capitalize on market opportunities must navigate these challenges effectively, focusing on cost reduction strategies, regulatory compliance, and supply chain optimization. By doing so, they can successfully leverage the productivity benefits of robotic injection molding machines and stay competitive in the evolving manufacturing landscape.

What will be the Size of the Robotic Injection Molding Machine Market during the forecast period?

- The market in the US is experiencing significant growth, driven by the increasing demand for automation and robotics in various industries. This market caters to consumer goods, packaging, material handling, electronics, medical sectors, and industrial equipment, among others. The integration of servo-driven technology and precision control in these machines enhances productivity and product quality. Geographical expansions and mergers are key trends in the market, as medium-sized enterprises seek to expand their footprint and enhance their capabilities. The use of recycled materials and biodegradable plastics aligns with sustainability efforts and addresses environmental issues. Waste reduction is a critical consideration, with servo sprue pickers and part removal systems optimizing the manufacturing process.

- The medical sectors, in particular, benefit from the increased precision and efficiency of robotic injection molding machines. Artificial intelligence and collaborative robots are transforming the industry, enabling more complex processes and reducing the need for skilled technicians. The rising population and the increasing focus on automation are expected to further fuel market growth. The others category, including rubber and ceramics, also presents opportunities for growth, as these materials can be processed using robotic injection molding machines to create high-quality, customized parts. Overall, the market for robotic injection molding machines in the US is poised for continued expansion, driven by the need for automation, precision, and waste reduction.

How is this Robotic Injection Molding Machine Industry segmented?

The robotic injection molding machine industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Automotive

- Consumer goods

- Packaging

- Others

- Type

- Plastics

- Rubber

- Others

- Geography

- North America

- US

- Europe

- Germany

- APAC

- China

- India

- Japan

- Rest of World (ROW)

- North America

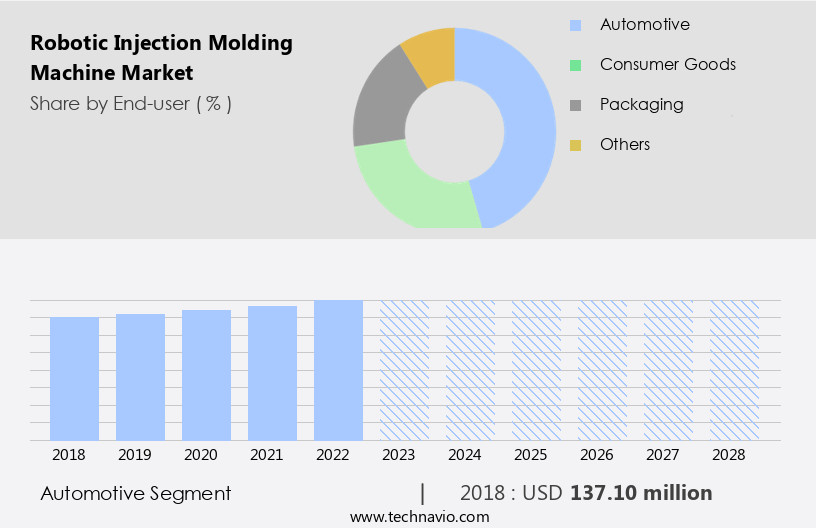

By End-user Insights

The automotive segment is estimated to witness significant growth during the forecast period.

The market is witnessing significant growth, particularly in industries such as automotive and medical sectors. Precision and productivity are key factors driving the adoption of these machines. In the automotive industry, the trend towards lean and flexible manufacturing, reduced lead times, and increased competition is leading to increased investment in robotic systems. This includes robotic injection molding machines, which enable the production of fuel-efficient components, aiding in the development of electric and hybrid vehicles. Medium-sized enterprises are also embracing robotic injection molding machines to enhance efficiency and reduce waste. Geographical expansions and mergers are contributing to market growth, as companies seek to expand their operations and enhance their capabilities.

The integration of artificial intelligence and machine learning is enabling advanced control and automation, further increasing productivity. The medical sector is another significant market for robotic injection molding machines, with a focus on producing high-quality, biodegradable medical components. Collaborative robots and skilled technicians are essential in this industry to ensure the production of complex, customized parts. The electronics industry is also adopting robotic injection molding machines to produce intricate components with high precision. Environmental concerns are driving the use of recycled materials and sustainable practices in injection molding. Industry standards and regulations are ensuring the adoption of efficient material handling and assembly processes.

The packaging industry is also benefiting from the use of robotic injection molding machines for the production of customized and automated packaging solutions. The hydraulic and servo-driven technology segments are dominating the market, with side entry robots and control systems enabling greater flexibility and efficiency. The market is expected to continue growing, with rising population demand for consumer goods and the increasing use of injection molded products in various industries. However, decreased demand in certain sectors and the high upfront financial outlays for these machines may pose challenges. Injection molding machines are essential for the production of molded plastic products, and the integration of automation and robotics is enhancing their capabilities and productivity.

The Automotive segment was valued at USD 137.10 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

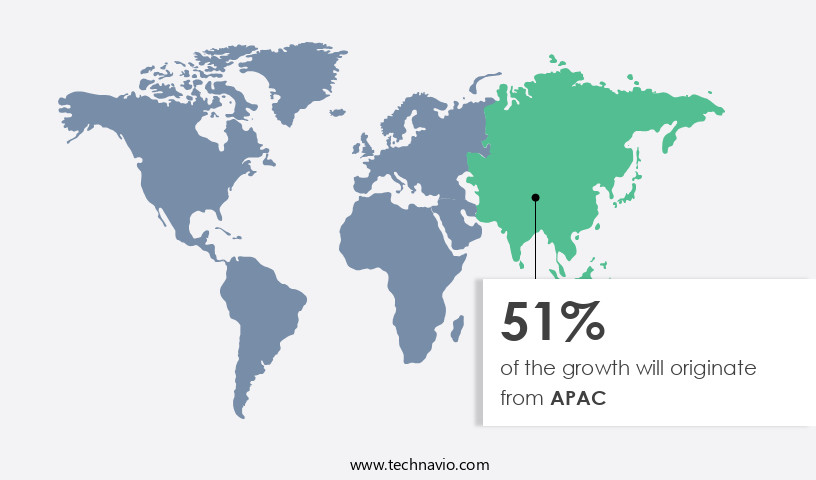

APAC is estimated to contribute 51% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market is witnessing significant growth, particularly in the APAC region. China, as the world's manufacturing hub, is leading the charge with a substantial increase in demand for robots. Moreover, there is a growing trend towards automation and robotics in developing markets like Vietnam, Thailand, and India, providing ample opportunities for market participants. Companies are capitalizing on this trend by expanding their presence in these countries through new manufacturing facilities. Precision and productivity are key drivers in the market, with medium-sized enterprises and the medical sectors being significant consumers. Waste reduction and the use of recycled materials are also gaining importance in the industry, aligning with sustainability concerns.

Mergers and acquisitions have been prevalent, with electric machines, servo sprue pickers, and side entry robots being popular areas of focus. Artificial intelligence and machine learning are increasingly being integrated into injection molding machines for improved control and efficiency. Collaborative robots and skilled technicians are essential for the assembly and packaging processes. The market caters to various industries, including electronics, automotive, and consumer goods, among others. Environmental concerns are influencing the market, with a shift towards biodegradable materials and hybrid machines. Decreased demand in certain geographic regions, such as Europe, is a challenge. However, advancements in technology, such as inmold labeling and servo-driven technology, are expected to drive growth.

Industry standards and upfront financial outlays are crucial factors influencing market dynamics. Productivity, efficiency, and product quality are essential considerations for businesses investing in injection molding machines. The market for molded plastic products is vast, with plastic usage continuing to rise due to its versatility and cost-effectiveness. Despite the challenges, the future of the market looks promising, with continued innovation and automation shaping its evolution.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Robotic Injection Molding Machine market drivers leading to the rise in the adoption of Industry?

- The significant productivity enhancements delivered by robotic injection molding machines serve as the primary catalyst for market growth.

- Robotic injection molding machines have gained significant traction in the manufacturing sector due to their ability to produce large quantities of molded plastic products with high accuracy, productivity, and consistency. The hydraulic segment of robotic injection molding machines is particularly popular due to its long reach and flexibility. Robots integrated with injection molding machines offer numerous benefits, including increased speed, safety, and reliability. Robots can maintain a consistent production speed, eliminating downtime and ensuring uniform product quality. Moreover, the initial upfront financial outlays for robotic injection molding machines can be offset by the cost savings from increased productivity and material handling efficiency.

- However, environmental concerns surrounding plastic usage and sustainability are becoming increasingly important. Automation in injection molding processes enables manufacturers to address these issues by optimizing material usage and reducing waste. Overall, the adoption of robotic injection molding machines contributes to the growth of the injection molding industry while addressing the need for increased efficiency, quality, and sustainability.

What are the Robotic Injection Molding Machine market trends shaping the Industry?

- The robotic injection molding process is experiencing an emerging trend towards the greater adoption of collaborative robots, or cobots. This increase in cobot usage is a significant development in the industry.

- The market is experiencing significant growth due to the increasing adoption of collaborative robots, or cobots, in various industrial processes. These machines, which are capable of working in conjunction with human workers, offer numerous benefits, including waste reduction, precision, and improved safety. Cobots are particularly effective in the manufacturing of rubber and ceramics, as well as in the medical sectors. Cobots utilize advanced technologies such as artificial intelligence and specialized sensors to optimize their performance and collaborate with human workers. They can perform repetitive tasks with high accuracy and speed, freeing up skilled technicians for more complex tasks. Furthermore, the use of cobots enables medium-sized enterprises to invest in industrial equipment without the need for large capital expenditures.

- Companies in the market are focusing on mergers and geographical expansions to increase their market share and offer more comprehensive solutions to customers. The integration of cobots in injection molding processes results in increased productivity, improved product quality, and reduced labor costs. Additionally, the use of cobots in part removal processes further streamlines the manufacturing process and enhances overall efficiency. The "Others" category, which includes applications in areas such as research and development, is also expected to witness significant growth in the coming years.

How does Robotic Injection Molding Machine market faces challenges face during its growth?

- The high initial cost is a significant challenge impeding the growth of the robotic systems industry.

- Robotic injection molding machines offer significant advantages in terms of productivity and efficiency, particularly for manufacturing electronics and metal molded products. However, their high cost, which includes expenses for sensors, software, advanced technologies, fixtures, tooling, and environmental systems, deters many small- and medium-sized enterprises (SMEs) from investing. Despite the initial investment, the use of robotic systems can lead to cost savings and improved product quality over time. Environmental concerns are driving the adoption of biodegradable materials and recycled materials in injection molding. Industry standards for sustainability are increasingly stringent, and companies are seeking ways to reduce their carbon footprint.

- Robotic systems can facilitate the use of these materials by ensuring consistent processing and reducing waste. Acquisitions and technological advancements are shaping the market. For instance, the integration of servo sprue pickers and electric machines has improved the precision and speed of the manufacturing process. Assembly and packaging processes have also been automated, further increasing productivity. Despite the benefits, the high cost of robotic systems remains a barrier to entry for many SMEs.

Exclusive Customer Landscape

The robotic injection molding machine market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the robotic injection molding machine market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, robotic injection molding machine market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

All Plastics LLC - Robotic injection molding machines, including those designed for medical and clean room applications, offer versatility in various industries.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- All Plastics LLC

- Biomerics LLC

- BORCHE North America INC.

- C and J Industries Inc.

- Currier Plastics Inc.

- D and M Plastics LLC

- ENGEL Austria GmbH

- EVCO Plastics

- Formplast GmbH

- H and K Muller GmbH and Co. KG

- Hehnke GmbH and Co KG

- HTI Plastics

- Husky Technologies

- Majors Plastics Inc.

- Mold Hotrunner Solutions Inc.

- Proto Labs Inc.

- Tessy Plastics Corp.

- The Rodon Group

- TR Electronic

- Woojin Plaimm Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Robotic Injection Molding Machine Market

- In February 2024, Bosch Rexroth, a leading industrial technology provider, unveiled its new Rexroth Robotic Injection Molding Machine, integrating advanced robotics and injection molding technologies to enhance production efficiency and product quality (Bosch Rexroth press release, 2024). This innovation represents a significant technological advancement in the robotic injection molding market.

- In October 2025, Siemens AG and Sumitomo (SHI) Demag, a global leader in injection molding machinery, announced their strategic partnership to develop intelligent, connected injection molding machines with integrated robotics and Industry 4.0 capabilities (Siemens AG press release, 2025). This collaboration marks a major strategic move to cater to the growing demand for smart manufacturing solutions in the market.

- In March 2024, KraussMaffei, a renowned manufacturer of machinery for plastics processing, raised â¬200 million in funding to expand its production capacity and invest in research and development, including robotic injection molding technologies (KraussMaffei press release, 2024). This substantial investment underscores the market's potential and the commitment of key players to stay competitive.

- In January 2025, Jabil, a leading manufacturing solutions provider, opened a new advanced manufacturing facility in the United States, featuring state-of-the-art robotic injection molding machines to produce high-volume, complex parts for various industries (Jabil press release, 2025). This geographic expansion signifies a key market entry for Jabil and highlights the growing importance of North America in the global robotic injection molding market.

Research Analyst Overview

The market is experiencing dynamic and evolving patterns as the industry continues to innovate and adapt to various market trends. Rubber and ceramics are among the materials that are increasingly being molded using robotic systems, as these machines offer enhanced precision and consistency compared to traditional methods. Geographical expansions have been a significant trend in the market, with medium-sized enterprises (MSEs) in various geographic regions investing in these advanced technologies to improve productivity and efficiency. The integration of artificial intelligence (AI) and machine learning algorithms into injection molding machines is revolutionizing the industry, enabling real-time process optimization and predictive maintenance.

Waste reduction is another key driver of the market. These machines are designed to minimize waste by optimizing material usage and reducing the need for skilled technicians to manually operate the machines. The use of recycled materials and biodegradable plastics is also gaining traction in the industry, addressing environmental concerns and contributing to sustainability efforts. Mergers and acquisitions have been common in the industrial equipment sector, with major players acquiring smaller companies to expand their product offerings and enter new markets. Collaborative robots, or cobots, are a growing segment of the market, offering increased flexibility and ease of use for small and medium-sized businesses.

The medical sectors are also adopting robotic injection molding machines for the production of medical devices and pharmaceutical packaging. The use of electric machines and servo sprue pickers is becoming increasingly prevalent, as they offer improved energy efficiency and reduced maintenance requirements. The automotive industry, a major consumer of injection molded products, is also embracing automation and robotics to enhance productivity and reduce costs. The assembly and packaging processes are being automated, with robots handling tasks such as part removal and in-mold labeling. The hydraulic segment of the injection molding machine market is being challenged by the increasing popularity of servo-driven technology, which offers greater precision and energy efficiency.

Side entry robots are also gaining traction, as they offer easier access to the mold and improved flexibility. Control systems are a critical component of injection molding machines, and the industry is seeing the adoption of advanced technologies such as machine learning and AI to optimize production processes and improve product quality. The use of robotics in injection molding is also contributing to increased productivity and efficiency, as these machines can work continuously without the need for breaks or rest periods. The plastic usage trend is a significant factor in the injection molding industry, with the market seeing a rise in demand for plastic molded products due to their versatility and cost-effectiveness.

However, environmental issues related to plastic waste and usage are becoming increasingly prominent, and the industry is responding by exploring the use of biodegradable and recycled materials. Industry standards and regulations are also influencing the market, with companies investing in technologies that meet these requirements and ensure product quality. Upfront financial outlays for these advanced machines can be significant, but the long-term benefits in terms of productivity, efficiency, and sustainability make them a worthwhile investment for many businesses.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Robotic Injection Molding Machine Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

167 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.36% |

|

Market growth 2024-2028 |

USD 109.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.12 |

|

Key countries |

China, US, Germany, India, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Robotic Injection Molding Machine Market Research and Growth Report?

- CAGR of the Robotic Injection Molding Machine industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the robotic injection molding machine market growth of industry companies

We can help! Our analysts can customize this robotic injection molding machine market research report to meet your requirements.