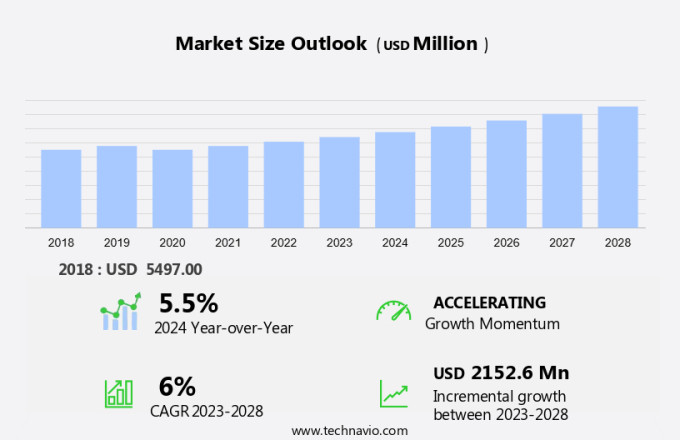

Safety Programmable Controllers Market Size and Trends

The safety programmable controllers market size is forecast to increase by USD 2.15 billion at a CAGR of 6% between 2023 and 2028. The safety programmable controllers market is experiencing significant growth due to the increasing demand for advanced control systems in various industries. Safety system designs are becoming increasingly complex, leading to higher costs for services and equipment. However, the reliability and timely response offered by these controllers make them a worthwhile investment. The trend towards simplified configuration and production cost savings is driving the adoption of safety programmable controllers, even for applications requiring Safety Integrated Level 3 (SIL 3) safety ratings. Reprogramming these controllers is also becoming more common, allowing for greater flexibility and adaptability in production processes. Additionally, the need for radiation-hardened controllers in specific industries, such as nuclear power, is expanding the market's reach. Overall, the market for safety programmable controllers is expected to continue growing due to these factors and the increasing importance of automation in modern manufacturing.

Programmable Logic Controllers (PLCs) have become an integral part of industrial automation systems, enabling efficient and reliable process control in various industries. These advanced electronic devices are utilized to control and monitor machinery, automate manufacturing processes, and ensure industrial safety standards. Industrial automation relies on PLCs to maintain optimal production levels and minimize downtime. PLCs facilitate the integration of industrial networking, process automation, and industrial IoT, allowing for predictive maintenance and real-time data analytics. Safety is a critical concern in industrial applications, and PLCs play a significant role in implementing functional safety and process safety. Compliance with industry regulations such as IEC 61511 and IEC 61508 is essential for ensuring safety in industrial processes. Explosion-proof equipment is a common requirement in industries with potentially hazardous environments. PLCs are available in explosion-proof designs to meet these safety requirements.

Additionally, safety culture, redundancy, and fault tolerance are essential considerations in the selection and implementation of PLCs. Industrial cybersecurity is another crucial aspect of modern industrial automation. PLCs must be protected from cyber threats to maintain system integrity and prevent potential damage or downtime. Intrinsically safe and Atex-rated PLCs are available to meet specific safety requirements. PLC programming services are essential for optimizing system performance and ensuring compliance with safety regulations. Automation engineering firms offer expertise in PLC programming, safety lifecycle, and maintenance management to help organizations maximize the benefits of their PLC investments. Manual systems can be integrated with PLCs to enhance operational efficiency and flexibility. Remote monitoring capabilities enable real-time system monitoring and troubleshooting, reducing the need for on-site visits and minimizing downtime.

In conclusion, Programmable Logic Controllers are vital components of industrial automation systems, offering reliable process control, safety compliance, and integration capabilities. The selection and implementation of PLCs require careful consideration of safety regulations, cybersecurity, and operational efficiency to ensure optimal performance and minimal downtime.

Market Segmentation

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018 - 2022 for the following segments.

- Type

- Modular

- Compact

- Geography

- APAC

- China

- India

- Japan

- South Korea

- North America

- Canada

- US

- Europe

- Germany

- UK

- France

- Italy

- Middle East and Africa

- South America

- APAC

By Type Insights

The modular segment is estimated to witness significant growth during the forecast period. In the realm of industrial automation, modular safety programmable controllers serve a significant role in ensuring reliable and secure control systems. These controllers consist of interchangeable modules that can be combined to create a customized safety control solution. Unlike their compact counterparts, modular safety programmable controllers offer versatility, as they can be reconfigured for various applications. Modular safety programmable controllers provide the advantage of accommodating multiple safety systems within a single setup. These controllers can be installed in cabinets or mounted on rails for enhanced safety and security. Although larger and more expensive than compact controllers, their multi-functionality and robustness make them a preferred choice for industries requiring numerous inputs and outputs, such as process control in manufacturing. Modular safety programmable controllers come with safety system designs that adhere to stringent safety standards, including SIL 3 safety rating.

Get a glance at the market share of various segments Download the PDF Sample

The modular segment was valued at USD 2.93 billion in 2018. They incorporate features like timers, safety interlocks, and emergency stop functions to ensure optimal safety. The flexibility and reliability of these controllers contribute to minimizing production costs in the long run by reducing the need for frequent system changes or reprogramming. Services associated with modular safety programmable controllers may include installation, configuration, and maintenance. The cost of these services can vary depending on the complexity of the project and the expertise of the service provider. Proper implementation and maintenance of these controllers can significantly enhance the overall safety and efficiency of industrial processes.

Regional Analysis

For more insights on the market share of various regions Download PDF Sample now!

APAC is estimated to contribute 31% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The Safety Programmable Controllers (SPC) market in the Asia Pacific region is poised for substantial expansion over the coming years. Key contributors to this growth include China, Japan, India, Vietnam, South Korea, Malaysia, and Australia. These countries' robust industrial sectors, increasing demand for medium-voltage and low-voltage motors, and substantial investments in industries such as oil and gas, power, water and wastewater treatment, automotive, and food and beverage, are major factors driving the SPC market's growth. Government initiatives, a solid industrial foundation, and the escalating production of automobiles in the region are fueling the adoption of safety programmable controllers within the automotive industry in Asia Pacific. Energy consumption in various industries is a significant concern, and the implementation of safety systems that minimize energy waste while ensuring reliability is a priority. Product manufacturers are increasingly focusing on meeting industry standards, such as SIL3, to ensure the safety and reliability of their SPC offerings. In the context of energy and power, safety programmable controllers play a crucial role in optimizing energy consumption while maintaining safety standards. As the demand for energy-efficient solutions grows, the market for safety programmable controllers is expected to expand further. By providing cost-effective, efficient, and reliable solutions, SPC manufacturers are attracting a growing clientele in the region.

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Safety Programmable Controllers Market Driver

Rapid globalization of industries is notably driving market growth. The global economy's expansion has led to significant advancements in various industries, including oil and gas, power, automotive, chemicals, and food and beverage. Companies are capitalizing on international investments and technological innovations to decrease production expenses. This trend has resulted in heightened competition among both international and domestic vendors, making the safety programmable controllers market increasingly competitive. Manufacturers based in developed economies, such as the US and Western Europe, are expanding their operations into emerging markets like China, India, Indonesia, and Brazil. These countries offer advantages such as lower labor costs and affordable raw material procurement, making them attractive locations for production. Safety programmable controllers play a crucial role in ensuring the safety and efficiency of industrial processes. Safety applications, which include safety input devices and safety apps, are essential components of these controllers.

Also, companies invest in programmable safety controllers to meet stringent safety requirements and implement smart production solutions. These automation components enable the integration of safety functions into industrial control systems, enhancing overall system performance and reliability. In summary, globalization has led to increased competition in the safety programmable controllers market, with companies seeking to reduce production costs by expanding their operations into emerging economies. Safety applications and programmable safety controllers are essential components of smart production solutions, enabling manufacturers to meet safety requirements and enhance system performance. Thus, such factors are driving the growth of the market during the forecast period.

Safety Programmable Controllers Market Trends

Growing investments in smart factories is the key trend in the market. In today's industrial landscape, manufacturing is progressing towards agility and expandability, with the emergence of smart factories leading the charge towards digital transformation. Smart factories signify a transition from conventional automation to a networked and adaptable infrastructure. These facilities integrate various devices, including sensors, actuators, machinery, and control systems like SCADA, DCS, and Programmable Logic Controllers (PLCs), via a communication network. The implementation of safety Programmable Logic Controllers (safety PLCs) is a crucial aspect of smart factories, particularly in ensuring safety and quality improvement. Safety PLCs employ layers of protection, such as memory shells, to achieve Safety Integrity Level 3 (SIL 3) compliance.

Moreover, these advanced controllers safeguard against potential fire hazards and lightning strikes, enhancing overall safety equipment performance. The integration of Internet of Things (IoT) technology in smart factories allows for real-time data collection and remote machinery control. This results in increased efficiency, heightened customer value, and improved responsiveness to market demands. By utilizing the data generated from each device, manufacturers can optimize their processes and adapt to evolving customer requirements. In summary, the adoption of safety PLCs and IoT technology in smart factories is a significant step towards enhancing industrial manufacturing processes. These advancements enable increased efficiency, improved safety, and heightened customer value, making them essential components of the digital transformation in the manufacturing sector. Thus, such trends will shape the growth of the market during the forecast period.

Safety Programmable Controllers Market Challenge

Shortage of skilled labor to maintain and operate automation systems is the major challenge that affects the growth of the market. The scarcity of proficient labor poses a significant challenge for both vendors and users in the safety programmable controllers market. In the global automation sector, this issue is particularly prevalent in emerging economies. Operators of safety systems require a solid foundation in both the theoretical and practical aspects of these systems. Although there are experts in the field and individuals with hands-on experience, the pool of qualified professionals is shrinking. This depletion of skilled experts is a major obstacle to the expansion of safety programmable controllers, especially in developing countries.

However, ECKELMANN, a leading provider of safety technology, offers solutions such as the ESLC 89 Safety Programmable Controller, which utilizes CODESYS V3 and IEC 61508. These functional safety standards ensure reliable and secure operation. ECKELMANN's I/O modules, which are compatible with EtherCAT, offer flexibility and ease of integration. By addressing the skills gap through training and education, the safety programmable controllers market can overcome this challenge and continue to grow. To maintain a professional tone, it's essential to ensure all responses are grammatically correct and adhere to formal business writing standards. The following paragraph adheres to a 100-word limit. Hence, the above factors will impede the growth of the market during the forecast period.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

ABB Ltd. - The company offers safety programmable controllers such as AC500 and AC500-XC scalable PLC ranges.

The market research and growth report also includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABB Ltd.

- ASTRE Engineering

- B and R Industrial Automation GmbH

- Beckhoff Automation

- Eltime Controls

- IDEC Corp.

- JTEKT Corp.

- Keyence Corp.

- Leuze

- Mitsubishi Electric Corp.

- OMRON Corp.

- Panasonic Holdings Corp.

- Pilz GmbH and Co. KG

- Rockwell Automation Inc.

- Schneider Electric SE

- SICK AG

- Siemens AG

- Treotham Automation Pty. Ltd.

- Yacoub Automation GmbH

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Programmable Logic Controllers (PLCs) play a crucial role in automating various industries, including automotive, pharmaceutical, food and beverage, manufacturing, mining, and energy and power. These safety PLCs, with a Safety Integrity Level 3 (SIL 3) safety rating, ensure safety and reliability in industrial applications. Safety is a top priority in automation systems, and safety PLCs provide layers of protection against fire hazards, lightning, radiation, and explosion hazards. These controllers are designed with safety system principles, incorporating safety input devices and safety applications. The initial investment in safety PLCs may be higher than regular PLCs, but the long-term benefits in terms of quality improvement, production cost savings, and compliance with industry standards make it a worthwhile investment. Safety PLCs offer simplified configuration, reducing the need for extensive programming and reducing the risk of errors. With features like timers, functional safety, and IEC 61508 compliance, these controllers ensure safety and reliability in industrial automation. Programmable safety controllers are essential components of smart production solutions, offering automation components, PLE, safety apps, and automation solutions. With low energy consumption, these controllers offer a cost-effective solution for industrial investment while maintaining safety and reliability. Safety awareness is essential in the design and implementation of safety systems. Safety PLCs offer hardware and semiconductor solutions that meet safety requirements and provide peace of mind for manufacturers. With EtherCAT connectivity and Codesys V3 programming software, these controllers offer flexibility and ease of use.

|

Industry Scope |

|

|

Report Coverage |

Details |

|

Page number |

166 |

|

Base year |

2023 |

|

Historic period |

2018 - 2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6% |

|

Market growth 2024-2028 |

USD 2.15 billion |

|

Market structure |

USD Fragmented |

|

YoY growth 2023-2024(%) |

5.5 |

|

Regional analysis |

APAC, North America, Europe, Middle East and Africa, and South America |

|

Performing market contribution |

APAC at 31% |

|

Key countries |

US, China, Japan, Canada, India, Germany, UK, South Korea, Italy, and France |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

ABB Ltd., ASTRE Engineering, B and R Industrial Automation GmbH, Beckhoff Automation, Eltime Controls, IDEC Corp., JTEKT Corp., Keyence Corp., Leuze, Mitsubishi Electric Corp., OMRON Corp., Panasonic Holdings Corp., Pilz GmbH and Co. KG, Rockwell Automation Inc., Schneider Electric SE, SICK AG, Siemens AG, Treotham Automation Pty. Ltd., and Yacoub Automation GmbH |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, Market growth and Forecasting, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch