Molecular Sieves Market Size 2025-2029

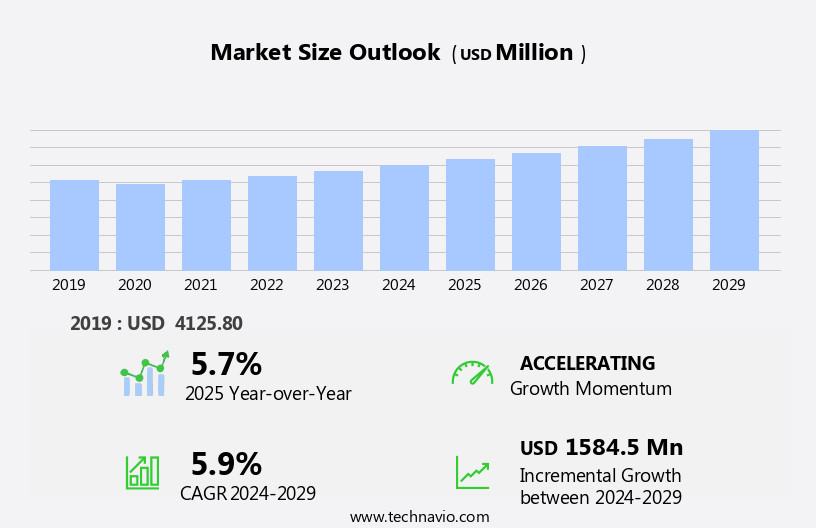

The molecular sieves market size is forecast to increase by USD 1.58 billion, at a CAGR of 5.9% between 2024 and 2029.

- The market is driven by the expanding application scope of molecular sieves as catalysts, particularly in the oil and gas industry. These materials, renowned for their exceptional adsorptive properties, are increasingly utilized to enhance the efficiency and productivity of various processes. Notably, their role in the refining and petrochemical sectors is gaining significant traction, as they facilitate the separation and purification of gases and liquids. However, the market is not without challenges. Risks associated with molecular sieves, such as potential deactivation due to moisture absorption and thermal instability, pose significant hurdles. These issues can lead to operational inefficiencies, increased costs, and potential safety concerns.

- Companies operating in this market must invest in research and development to mitigate these challenges and improve the durability and reliability of molecular sieves. By addressing these obstacles, businesses can capitalize on the burgeoning demand and secure a competitive edge in the evolving market landscape.

What will be the Size of the Molecular Sieves Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2019-2023 and forecasts 2025-2029 - in the full report.

Request Free Sample

The market continues to evolve, driven by the diverse applications in various sectors. Temperature swing adsorption, vacuum swing adsorption, and pressure swing adsorption are essential processes that underpin the market's growth. These techniques, which utilize the unique adsorptive properties of molecular sieves, enable gas separation, hydrogen purification, and oxygen generation, among others. In petrochemical refining, molecular sieves play a crucial role in fluid catalytic cracking and natural gas processing. Their high mechanical strength, thermal stability, and chemical stability make them indispensable in these processes. However, the market's dynamics are not limited to these applications. Environmental impact is a growing concern, leading to increased demand for molecular sieves in CO2 capture and water treatment.

Regulatory compliance and safety standards are essential considerations, necessitating rigorous quality control and technical support. The manufacturing process of molecular sieves involves intricacies such as pore size distribution, particle size, and specific surface area. These performance metrics, along with lifecycle analysis and material science, are essential for optimizing processes and designing application-specific solutions. The supply chain is another critical aspect of the market, with distribution networks and pricing strategies influencing market trends. Activated carbon and mass spectrometry are complementary technologies that expand the market's scope. Membrane separation and ion exchange are emerging technologies that offer potential for further growth.

In the realm of chemical engineering, molecular sieves are a versatile tool for process optimization, nitrogen generation, and cryogenic separation. Their role in air purification and gas chromatography further underscores their importance. As the market continues to unfold, the ongoing evolution of molecular sieves and their applications promises to deliver new opportunities and challenges.

How is this Molecular Sieves Industry segmented?

The molecular sieves industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Grade Type

- 3A

- 4A

- 13X

- Others

- End-user

- Oil and gas industry

- Petrochemical industry

- Process industries

- Construction industry

- Others

- Type

- Beads

- Pellets

- Powder

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Grade Type Insights

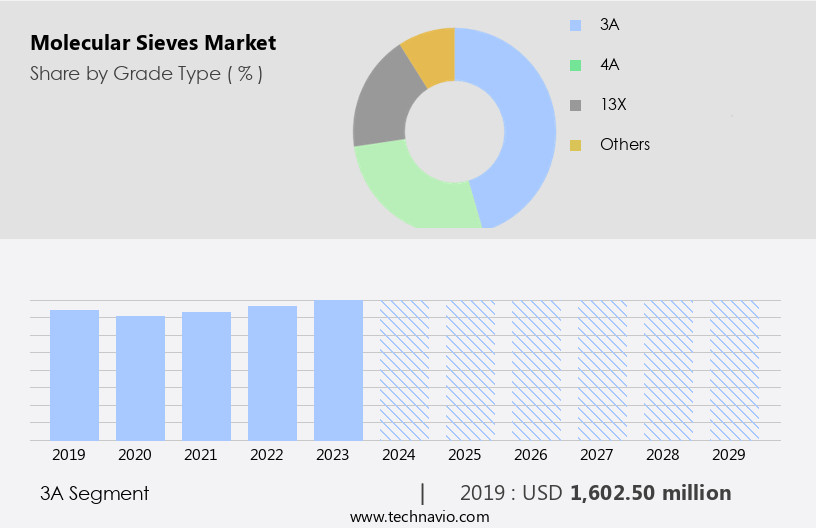

The 3a segment is estimated to witness significant growth during the forecast period.

Molecular sieve 3A is an alkali metal aluminosilicate with a pore size of about 3A. Grade 3A segment products are produced when sodium ions are replaced by potassium ions present in the crystal structure of the molecular sieve. The main component of a grade 3A molecular sieve is aluminosilicate. Molecular sieve 3A is mainly used to remove moisture from liquefied gas. The advantages of 3A molecular sieves are high crushing resistance, high pollution resistance, and a high number of cycles, which ensures a long product life.

The 3A segment was valued at USD 1.6 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

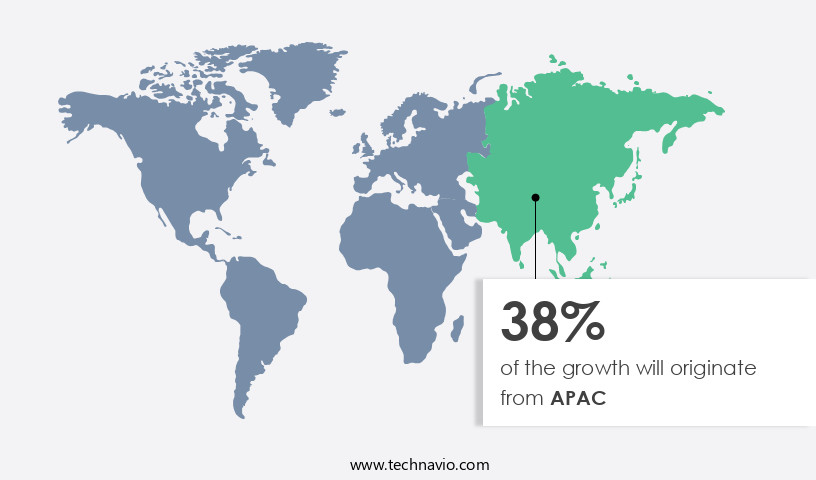

APAC is estimated to contribute 38% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market experiences significant growth due to increasing demand from various industries, particularly in emerging economies like India and China. Chinese manufacturing units prioritize consistent quality and competitive pricing to maintain long-term customer relationships. The regional market is primarily driven by the robust demand for molecular sieves in natural gas processing, with China being the fourth-largest natural gas producer. The oil and gas industry in countries such as China and India, which are significant producers, fuels the demand for molecular sieves to dry and purify feedstocks and organic gases. Molecular sieves play a crucial role in various applications, including fluid catalytic cracking, water treatment, air purification, and natural gas processing.

Their unique properties, such as pore size distribution, mechanical strength, and regulatory compliance, make them indispensable in these industries. In the context of energy efficiency, molecular sieves contribute to process optimization and cryogenic separation, enhancing the overall performance of industrial processes. The market's evolution is influenced by advancements in material science, application-specific designs, and manufacturing processes. These innovations have led to improvements in specific surface area, thermal stability, and chemical stability, making molecular sieves increasingly valuable in gas separation, hydrogen purification, and petrochemical refining. Additionally, the growing focus on environmental impact and safety standards necessitates the use of molecular sieves in CO2 capture and nitrogen generation.

Molecular sieves are integral to various industries, including chemical engineering, ion exchange, and membrane separation. Their integration in these sectors is essential for achieving optimal performance metrics and ensuring quality control. The market's dynamics are further shaped by pricing strategies, bulk density, and silica gel, which impact the overall cost-effectiveness and efficiency of molecular sieves. In conclusion, the market is characterized by continuous innovation and growth, driven by the increasing demand for these materials in various industries. The unique properties of molecular sieves, coupled with advancements in material science and manufacturing processes, make them indispensable in applications such as natural gas processing, fluid catalytic cracking, water treatment, and air purification.

The market's evolution is shaped by factors such as energy efficiency, environmental impact, and safety standards, making molecular sieves a valuable investment for businesses seeking to optimize their industrial processes.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market is a significant segment of the global adsorbents industry, characterized by its production and application in various sectors. These versatile materials, known for their unique micro-porous structure, exhibit exceptional adsorption properties, making them indispensable in gas separation, water treatment, and chemical processing industries. Molecular sieves are primarily used as desiccants, drying agents, and gas purification agents. Their high selectivity and capacity for adsorbing specific gases, such as hydrogen, nitrogen, methane, and carbon dioxide, make them essential in natural gas processing and refining. Additionally, molecular sieves find extensive applications in the pharmaceutical and food industries due to their ability to remove impurities and moisture. With growing demand for cleaner energy sources and increasing focus on water treatment, the market is poised for substantial growth. Key applications include gas storage, petrochemicals, and specialty chemicals. The market is driven by factors such as increasing industrialization, stringent regulations, and technological advancements.

What are the key market drivers leading to the rise in the adoption of Molecular Sieves Industry?

- The increasing demand for molecular sieves as catalysts is the primary driving force behind the market's growth. Molecular sieves, with their unique adsorptive properties, have gained significant attention in various industries, including petrochemicals, pharmaceuticals, and food and beverage, due to their effectiveness as catalysts in enhancing productivity and improving product quality. As a result, the market for molecular sieves is experiencing robust expansion.

- Molecular sieves, a type of microporous material with customized pore size distributions, have gained significant attention in various catalytic applications due to their unique properties. These materials catalyze processes such as epoxidation, alkylation, and isomerization, and are integral to large-scale industrial processes like fluid catalytic cracking and hydrocracking. Zeolites, a primary type of molecular sieves, exhibit exceptional acid activity with shape-selective features that are not present in their amorphous counterparts. They also serve as effective supports for numerous catalytically active metals. Advancements in molecular sieve technology have led to the synthesis of an extensive range of aluminosilicate zeolites and molecular sieves with other elemental compositions.

- The synthesis techniques for these materials have evolved significantly since the initial discovery of synthetic zeolite molecular sieve types A, X, and Y. The specific surface area, particle size, mechanical strength, and regulatory compliance of molecular sieves make them ideal for gas separation and oxygen generation applications, ensuring energy efficiency and contributing to a harmonious balance between industrial productivity and environmental sustainability. A lifecycle analysis of molecular sieves reveals their long-term economic and environmental benefits, making them a preferred choice for businesses seeking customized solutions in the chemical industry.

What are the market trends shaping the Molecular Sieves Industry?

- The oil and gas industry is experiencing a significant increase in usage, representing a prominent market trend. This upward trend is noteworthy for professionals in this sector.

- Molecular sieves play a crucial role in various industries, including CO2 capture, fluid catalytic cracking, water treatment, air purification, and natural gas processing. These materials exhibit excellent thermal and chemical stability, making them ideal for harsh industrial conditions. In CO2 capture, molecular sieves facilitate the separation of CO2 from other gases through cryogenic separation. In fluid catalytic cracking, they prevent the formation of water hydrates, ensuring process optimization and protecting water-sensitive catalytic converters. Moreover, molecular sieves are essential in water treatment for removing impurities and improving water quality. In air purification, they are used for nitrogen generation and removing contaminants.

- The global market for molecular sieves is significant, with major players sourcing a substantial portion from APAC and European countries. The presence of numerous global companies in North America and Europe has led them to establish manufacturing plants in APAC to cater to the demand for molecular sieves in the Middle East and Africa (MEA) oil and gas, petrochemicals, and process industries. The molecular sieve dehydration process is essential in natural gas processing, as it removes water, preventing gas hydrates from forming and reducing corrosion. This, in turn, improves pipeline and process performance and protects water-sensitive catalytic converters in refinery processes.

What challenges does the Molecular Sieves Industry face during its growth?

- The molecular sieves' risks pose a significant challenge to the industry's growth, requiring continuous research and innovation to mitigate their impacts and ensure sustainable expansion.

- Molecular sieves are a type of adsorbent used extensively in various industries, including hydrogen purification and petrochemical refining, due to their unique ability to selectively adsorb gases based on their molecular size and shape. The manufacturing process of molecular sieves involves temperature swing adsorption, vacuum swing adsorption, and pressure swing adsorption. While molecular sieves offer numerous benefits, such as efficient gas separation and purification, they also present certain risks. For instance, they can cause skin and eye irritation if they come in contact with water, leading to the generation of intense heat. Ingestion and inhalation of molecular sieve products can pose health hazards.

- In the food and beverage industry, molecular sieves are used as desiccants to absorb moisture and prevent damage to packaged food products. However, the use of molecular sieves in food additives raises concerns regarding their environmental impact and potential contamination of food products. The market supply chain involves various stakeholders, including raw material suppliers, manufacturers, distributors, and end-users. Mass spectrometry and membrane separation are some of the alternative technologies used for gas separation and purification, which could impact the market dynamics. It is essential for manufacturers to adhere to regulatory guidelines and ensure the safe handling and disposal of molecular sieves to mitigate the associated risks.

Exclusive Customer Landscape

The molecular sieves market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the molecular sieves market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, molecular sieves market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

AGC Chemicals Pvt. Ltd. - The company specializes in providing molecular sieves, including Siliporite brand, for various industries.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- AGC Chemicals Pvt. Ltd.

- Arkema

- Axens Group

- BASF SE

- Brownell Ltd.

- CarboTech AC GmbH

- Desicca Chemicals Pvt. Ltd.

- FUJIFILM Corp.

- HengYe Inc.

- Honeywell International Inc.

- KNT Group

- KURARAY Co. Ltd.

- Merck KGaA

- Nanoshel LLC

- Resonac Holdings Corp.

- Sorbchem India Pvt Ltd.

- Vizag Chemical International

- W. R. Grace and Co.

- Zeochem AG

- ZR Catalyst Co. LTD.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Molecular Sieves Market

- In January 2024, Honeywell UOP, a leading technology and equipment provider, announced the launch of its new molecular sieve adsorbent, XP-10, designed for the removal of carbon dioxide (CO2) in natural gas processing applications (Honeywell UOP Press Release, 2024). This innovative product is expected to increase efficiency and reduce energy consumption by up to 20% compared to conventional molecular sieves.

- In March 2024, Linde plc, a global leader in gases, engineering, and technology, entered into a strategic partnership with NanoScience Instruments GmbH, a German nanotechnology company. The collaboration aimed to develop advanced molecular sieve materials for Linde's gas separation processes, enhancing their product portfolio and improving their competitive position in the market (Linde plc Press Release, 2024).

- In May 2024, PQ Corporation, a leading global provider of specialty materials, announced the acquisition of Molecular Sieves and Catalysts Business from Sigma-Aldrich Co. LLC. This acquisition expanded PQ Corporation's presence in the market, strengthening their position as a leading supplier of adsorbents and catalysts (PQ Corporation Press Release, 2024).

- In April 2025, Sabic, a leading global chemicals manufacturer, received regulatory approval from the U.S. Environmental Protection Agency (EPA) for its new methanol plant in Texas, which utilizes molecular sieves technology for CO2 capture and utilization. This plant is expected to reduce CO2 emissions by 1.2 million metric tons per year, making it a significant step towards sustainable production in the chemicals industry (Sabic Press Release, 2025).

Research Analyst Overview

- The market experiences dynamic activity driven by various factors, including environmental regulations and technological advancements. Joint ventures and technology licensing agreements are prevalent, shaping the competitive landscape. Kinetic models and column design play a crucial role in optimizing adsorption processes, while breakthrough curves and equilibrium isotherms guide product development. After-sales service, quality assurance, and customer relations are essential for maintaining brand positioning. Environmental regulations continue to influence market trends, pushing the adoption of synthetic zeolites and metal-organic frameworks (MOFs) for waste management and carbon capture. Intellectual property protection and process safety are key concerns, driving the need for rigorous risk assessment and process simulation.

- Strategic alliances and standards compliance are essential marketing strategies, ensuring product portfolio expansion and health and safety regulations adherence. Process safety, occupational safety, and life cycle assessment are integral to ensuring sustainable growth. Competitive adsorption, process simulation, and X, Y, and A-type zeolites are critical areas of research, driving innovation and performance enhancements. Quality assurance, pilot plants, and sales channels are essential elements of successful business operations. Marketing strategies, brand positioning, and sales channels are essential for capturing market share, with a focus on meeting customer needs and ensuring product differentiation. Health and safety, process safety, and risk assessment are crucial components of effective marketing strategies.

- In the market, after-sales service, product lifecycle management, and customer relations are vital for maintaining market presence and building long-term customer relationships. Competitive pricing, product innovation, and process efficiency are key drivers of growth. The market for molecular sieves is characterized by continuous innovation, with a focus on improving adsorption performance, reducing energy consumption, and enhancing product quality. Environmental regulations, process safety, and occupational safety are critical considerations, driving the adoption of advanced technologies and materials. Technology licensing and strategic alliances are prevalent, with companies collaborating to expand their product offerings and enhance their market presence.

- Environmental regulations, process safety, and occupational safety are critical considerations, driving the adoption of advanced technologies and materials. The market is driven by the need for efficient and effective adsorption technologies, with a focus on environmental sustainability and process safety. Companies are collaborating through strategic alliances and partnerships to expand their product offerings and enhance their market presence. The market is characterized by a high degree of competition, with companies continually seeking to improve their product offerings and gain a competitive edge. Marketing strategies, brand positioning, and sales channels are essential for capturing market share and maintaining customer loyalty.

- The use of kinetic models, column design, and competitive adsorption is driving innovation in the market. Process simulation and risk assessment are essential for optimizing production processes and ensuring process safety. In the market, after-sales service, quality assurance, and customer relations are essential for maintaining market presence and building long-term customer relationships. Standards compliance and process safety are critical considerations, with a focus on ensuring regulatory compliance and reducing risk. The market is characterized by a high degree of technological innovation, with a focus on improving adsorption performance, reducing energy consumption, and enhancing product quality.

- Intellectual property protection and process simulation are essential for ensuring product differentiation and competitive advantage. The market is driven by the need for efficient and effective adsorption technologies, with a focus on environmental sustainability and process safety. Companies are collaborating through joint ventures and technology licensing agreements to expand their product offerings and enhance their market presence. The market is characterized by a high degree of competition, with companies continually seeking to improve their product offerings and gain a competitive edge. Marketing strategies, brand positioning, and sales channels are essential for capturing market share and maintaining customer loyalty.

- The use of X, Y, and A-type zeolites, as well as other advanced materials, is driving innovation in the market. Process safety, occupational safety, and risk assessment are critical considerations, with a focus on ensuring regulatory compliance and reducing risk. In the market, after-sales service, quality assurance, and customer relations are essential for maintaining market presence and building long-term customer relationships. Process simulation and life cycle assessment are essential for optimizing production processes and reducing environmental impact. The market is characterized by a high degree of technological innovation, with a focus on improving adsorption performance, reducing energy consumption, and enhancing product quality.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Molecular Sieves Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

234 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.9% |

|

Market growth 2025-2029 |

USD 1584.5 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

5.7 |

|

Key countries |

US, China, Japan, Germany, India, UK, South Korea, Canada, France, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Molecular Sieves Market Research and Growth Report?

- CAGR of the Molecular Sieves industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the molecular sieves market growth of industry companies

We can help! Our analysts can customize this molecular sieves market research report to meet your requirements.