Abrasive Blasting Equipment Market Size 2024-2028

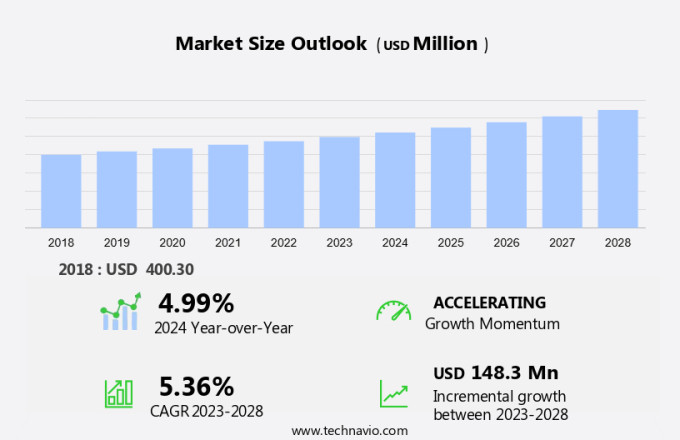

The abrasive blasting equipment market size is forecast to increase by USD 148.3 million, at a CAGR of 5.36% between 2023 and 2028.

- The market is witnessing significant growth due to several key trends. The rapid expansion of industries such as aerospace, healthcare, and furnishing is driving market demand. These industries rely heavily on abrasive blasting for surface preparation and finishing, leading to increased market penetration. Additionally, the growing adoption of e-commerce platforms is facilitating the sale of abrasive blasting equipment to a wider customer base. Furthermore, the integration of automation in abrasive blasting processes is streamlining operations and improving efficiency, making it an attractive investment for businesses. These factors collectively contribute to the market's strong growth.

What will be the Size of the Abrasive Blasting Equipment Market During the Forecast Period?

- The market in the United States is driven by the demand for efficient surface preparation solutions in various industries, including manufacturing sectors, graffiti removal, and marine maintenance. Abrasive blasting techniques, such as shot blasting, wet blasting, vacuum blasting, centrifugal blasting, soda blasting, steel grit blasting, bristle blasting, pencil blasting, bead blasting, and sandblasting, utilize diverse abrasive materials like aluminum oxide, glass beads, and silica sand to remove old coatings, rust, and other impurities. The market is segmented based on sales channels, including direct sales to OEMs, sales through distributors, and sales through online platforms. Cost-effective abrasive materials like plastic media and high-pressure techniques continue to gain popularity in the petrochemical industry.

The market is expected to grow steadily due to the increasing demand for superior surface preparation solutions.

How is this Abrasive Blasting Equipment Industry segmented and which is the largest segment?

The abrasive blasting equipment industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Manufacturing

- Construction and maintenance

- Others

- Type

- Semi automatic

- Automatic

- Manual

- Geography

- APAC

- China

- Japan

- North America

- US

- Europe

- Germany

- UK

- South America

- Middle East and Africa

- APAC

By End-user Insights

- The manufacturing segment is estimated to witness significant growth during the forecast period.

Abrasive blasting equipment is essential in metal manufacturing facilities for smoothing rough surfaces and removing burrs from welded or extruded metals. This process is widely used in various industries, including automotive, aerospace, shipbuilding, foundry, and rail manufacturing. The increasing demand for these products, particularly in the aerospace and automotive sectors, is driving market growth. Additionally, the growth in disposable income has led to an increase in personal vehicle purchases, further boosting demand for abrasive blasting machines. Key applications of abrasive blasting include peening and strengthening metals such as steel and aluminum, as well as removing surface contaminants like rust, paint, plastic, and fiberglass. In the manufacturing sector, the use of abrasive blasting equipment is a critical process for ensuring high-quality finished products.

Get a glance at the Abrasive Blasting Equipment Industry report of share of various segments Request Free Sample

The manufacturing segment was valued at USD 189.40 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

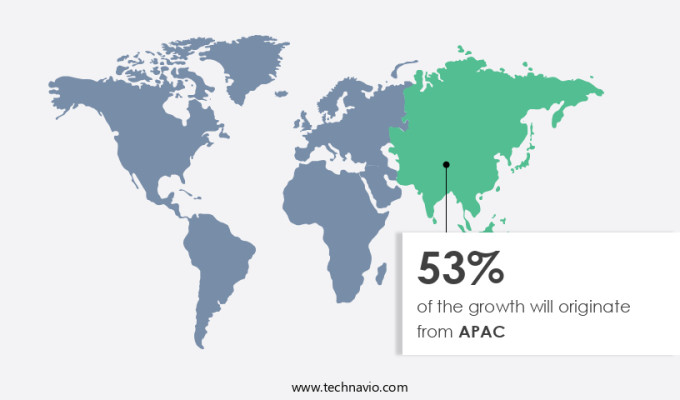

- APAC is estimated to contribute 53% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The market in APAC is experiencing growth due to the expansion of key industries such as automobile manufacturing and construction. In the automobile sector, the increasing production in countries like China, Korea, and India is driving demand for surface preparation techniques, including sand blasting and other methods like shot blasting, soda blasting, and wet blasting. The manufacturing sector also relies on abrasive blasting for graffiti removal and marine maintenance. Robotics and automation are increasingly being adopted for blasting processes to enhance efficiency and productivity. The construction sector's growth, driven by urbanization in APAC countries, is another significant factor fueling market growth.

Market Dynamics

Our abrasive blasting equipment market researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in adoption of Abrasive Blasting Equipment Industry?

Rapid growth in aerospace healthcare and furnishing industries is the key driver of the market.

- The market is experiencing significant growth due to the expanding application scope in various industries. Key sectors driving market expansion include automotive, construction, and aerospace. In the automotive industry, abrasive blasting is utilized for surface preparation, rust removal, and paint removal prior to repainting or coating. In the aerospace sector, blasting is essential for aircraft maintenance, cleaning surfaces, and removing unwanted deposits. Additionally, the marine industry relies on abrasive blasting for marine maintenance, graffiti removal, and preserving national monuments. The construction industry also leverages this technology for surface preparation, removing paint, rust, and other surface contaminants from concrete and other materials.

- Moreover, the healthcare sector is increasingly adopting abrasive blasting for manufacturing medical devices, specifically micro-abrasive blasting for cleaning small components. The growing healthcare sector, driven by a rising global population and technological advances, will fuel the demand for abrasive blasting equipment. The market offers various types of equipment, including sandblasting machines, shot blasting, wet blasting, vacuum blasting, centrifugal blasting, soda blasting, steel grit blasting, bristle blasting, pencil blasting, bead blasting, and manual abrasive blasting. The market caters to diverse industries such as petrochemicals, oil & gas, manufacturing, automotive, and more.

- Sales channels include direct sales (OEMs), sales through distributors, and sales through online platforms. Environmental regulations, high pressure, workplace safety standards, communication, and cost are crucial factors shaping the market. Environmental concerns, such as wastewater disposal and noise emissions, are driving the development of eco-friendly abrasive materials like glass beads, plastic media, and crushed glass grit. Additionally, the increasing industrialization and urbanization in metropolitan areas necessitate the use of efficient and cost-effective abrasive blasting equipment. In the manufacturing sector, abrasive blasting plays a crucial role in various processes like electroplating, pre-treatment, and blast cleaning.

What are the market trends shaping the Abrasive Blasting Equipment Industry?

Leveraging e-commerce to increase market penetration is the upcoming trend in the market.

- The market encompasses various types of machinery used for surface preparation, including sandblasting machines, shot blasting, wet blasting, vacuum blasting, centrifugal blasting, soda blasting, steel grit blasting, bristle blasting, pencil blasting, bead blasting, and manual abrasive blasting. These blasting techniques employ different abrasive materials like Aluminum oxide, glass beads, silica sand, plastic media, steel grit, crushed glass grit, and acrylic, fiberglass, wood, and metal beads. The market caters to diverse industries, such as manufacturing, automobile, marine, petrochemicals, aerospace & defense, and construction, among others. Market segments include portable/mobile and stationary/fixed equipment, with tank capacities ranging from less than 1000 L to above 3000 L.

- Robotics and automation have significantly influenced the market, with semi-automatic and automatic blasting systems gaining popularity. Applications include graffiti removal, coating removal, cleaning surfaces, and imparting texture. Environmental regulations and workplace safety standards are crucial factors shaping the market. Wastewater disposal and noise emissions are significant concerns. Cost-effective solutions, such as wet blasting, are gaining traction. The market is expected to grow due to increasing industrialization, the need for efficient surface preparation, and the expanding automotive, marine, and aviation industries. Blasting types include dry sand-blasting and wet sand-blasting, with control systems and various blasting media like silicon carbide, coal sag, and aluminum oxide grit.

What challenges does the Abrasive Blasting Equipment Industry face during its growth?

The growing use of automation is a key challenge affecting the industry growth.

- The market is witnessing significant growth due to the increasing demand for efficient surface preparation methods in various industries. This includes the automotive sector for removing unwanted deposits, graffiti removal in metropolitan areas, and marine maintenance in the shipping industry. Automation is playing a crucial role in this market, with the use of robotics and automation in blasting processes becoming increasingly popular. The use of different abrasive materials, such as Aluminum oxide, Silica sand, Steel grit, Glass beads, and Crushed Glass Grit, is essential in the blasting process. However, environmental regulations and workplace safety standards are becoming stricter, leading to concerns over wastewater disposal, noise emissions, and dust.

- To address these concerns, alternative blasting methods such as soda blasting and bead blasting are gaining popularity. The petrochemical industry, aerospace & defense, and construction industries are significant consumers of abrasive blasting equipment. Direct sales by OEMs, sales through distributors, and sales through online channels are the primary sales channels for these companies. The cost of abrasive blasting equipment varies depending on the tank capacity, blasting type, and control system. The market dynamics of the abrasive blasting equipment industry are influenced by factors such as increasing industrialization, the need for higher efficiency, and the growing demand for surface preparation in various industries.

Exclusive Customer Landscape

The abrasive blasting equipment market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The abrasive blasting equipment industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABShot Tecnics SL

- AGTOS GmbH

- Airblast BV

- Axxiom Manufacturing Inc.

- BLASTCORE LLC

- Burwell Technologies

- Clemco Industries Corp.

- Empire Abrasive Equipment

- Graco Inc.

- Guyson Corp.

- Kramer Industries Inc.

- ProBlast Inc.

- Raptor Blasting Systems LLC

- Sintokogio Ltd.

- Surface Finishing Equipment Co.

- Tip Plus Corp.

- torbo ENGINEERING KEIZERS GmbH

- Trinco Trinity Tool Co.

- Viking Corp.

- Vixen Surface Treatments Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a diverse range of tools and technologies used for surface preparation and cleaning applications. These equipment types cater to various industries, including manufacturing, construction, automotive, petrochemicals, aerospace & defense, and marine maintenance, among others. Abrasive blasting is an essential process in surface preparation, removing unwanted deposits, cleaning surfaces, and imparting texture. The market offers a variety of blasting equipment, including manual, semi-automatic, and fully automated systems. These systems come in various tank capacities, ranging from less than 1,000 liters to above 3,000 litres, and are available as portable/mobile or stationary/fixed units.

In addition, the market consists of different blasting types, such as sandblasting, shot blasting, wet blasting, soda blasting, steel grit blasting, bristle blasting, pencil blasting, bead blasting, and others. Abrasive materials used in these processes include aluminum oxide, silica sand, glass beads, plastic media, corn cob grit, and silicon carbide, among others. Industries like automotive, aerospace & defense, and marine maintenance heavily rely on abrasive blasting for various applications. For instance, in the automotive sector, blasting is used for rust removal, paint stripping, and surface preparation before painting. In the aerospace & defense industry, blasting is crucial for aircraft maintenance, including the removal of old paint and the application of new coatings.

In marine maintenance, blasting is used for cleaning and preparing surfaces for painting and coating. The petrochemical industry also utilizes abrasive blasting for various applications, such as surface preparation before welding, cleaning of equipment, and removing coatings. The process is also used in the oil & gas sector for pipeline preparation and cleaning of equipment. Robotics and automation have significantly influenced the market, with the integration of advanced control systems and automation technologies leading to increased efficiency and productivity. High-pressure blasting systems are also gaining popularity due to their ability to clean surfaces more effectively and quickly. Environmental concerns, including noise emissions and wastewater disposal, are essential factors driving the development of more eco-friendly blasting technologies.

|

Abrasive Blasting Equipment Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

168 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.36% |

|

Market Growth 2024-2028 |

USD 148.3 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.99 |

|

Key countries |

China, US, Germany, UK, and Japan |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the Abrasive Blasting Equipment industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.