Big Data In Manufacturing Market Size 2025-2029

The big data in manufacturing market size is valued to increase by USD 21.44 billion, at a CAGR of 26.4% from 2024 to 2029. Rising adoption of industry 4.0 will drive the big data in manufacturing market.

Major Market Trends & Insights

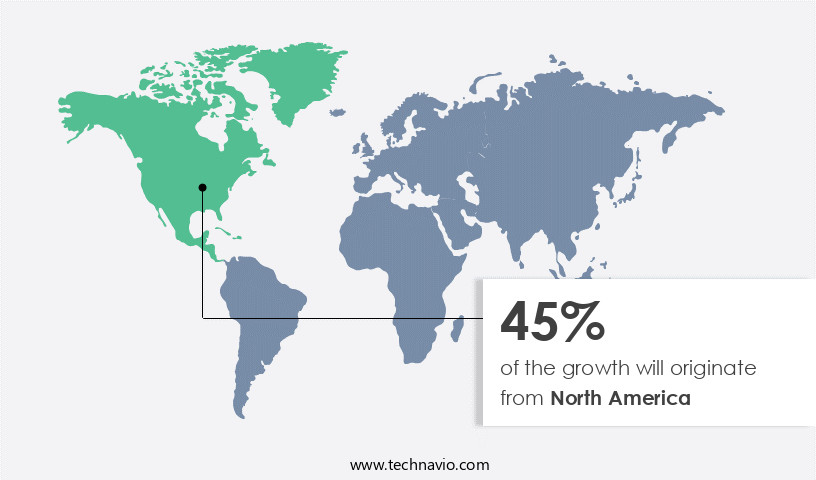

- North America dominated the market and accounted for a 50% growth during the forecast period.

- By Type - Services segment was valued at USD 2.9 billion in 2023

- By Deployment - On-premises segment accounted for the largest market revenue share in 2023

Market Size & Forecast

- Market Opportunities: USD 552.73 million

- Market Future Opportunities: USD 21444.10 million

- CAGR from 2024 to 2029 : 26.4%

Market Summary

- The market is witnessing significant growth due to the increasing adoption of Industry 4.0 and the emergence of artificial intelligence (AI) and machine learning (ML) technologies. These advanced technologies enable manufacturers to collect, process, and analyze vast amounts of data in real-time, leading to improved operational efficiency, enhanced product quality, and optimized supply chain management. One real-world business scenario demonstrating the impact of big data in manufacturing is supply chain optimization. By analyzing historical data and real-time information, manufacturers can predict demand patterns, optimize inventory levels, and reduce lead times. For instance, a leading automotive manufacturer was able to reduce its lead time by 15% by implementing predictive analytics in its supply chain management system.

- The complexity of big data analytics presents a challenge for manufacturers, as they need to invest in advanced technologies and skilled personnel to effectively process and interpret the data. However, the benefits far outweigh the costs, as manufacturers gain valuable insights that inform strategic decision-making, enhance customer satisfaction, and drive competitive advantage.

What will be the Size of the Big Data In Manufacturing Market during the forecast period?

Get Key Insights on Market Forecast (PDF) Request Free Sample

How is the Big Data In Manufacturing Market Segmented ?

The big data in manufacturing industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Type

- Services

- Solutions

- Deployment

- On-premises

- Cloud-based

- Hybrid

- Application

- Operational analytics

- Production management

- Customer analytics

- Supply chain management

- Others

- Geography

- North America

- US

- Canada

- Mexico

- Europe

- France

- Germany

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Type Insights

The services segment is estimated to witness significant growth during the forecast period.

In the dynamic and expansive realm of manufacturing, big data has emerged as a game-changer. By 2024, the services segment dominated market segmentation, with an estimated 45% market share. The manufacturing sector generates copious amounts of data from sensors, machines, production lines, and supply chains. This data deluge presents a rich opportunity for analytics and insights. Big data services empower manufacturers to optimize resource allocation, minimize operational inefficiencies, and uncover cost-saving opportunities, ultimately boosting profitability. Predictive maintenance using big data analytics minimizes downtime and reduces unplanned repairs, while real-time quality control ensures fewer defects, scrap, and rework, resulting in significant savings.

Additionally, big data analytics enable manufacturers to optimize supply chain operations through supply chain analytics, inventory management systems, and demand forecasting methods. Digital twin technology, process simulation software, and machine learning models facilitate energy efficiency monitoring, sustainable manufacturing practices, and waste reduction strategies. Cloud computing platforms and data integration pipelines streamline data access, while edge computing devices and manufacturing execution systems enable real-time data streams. Data security protocols safeguard sensitive information, and capacity planning models ensure efficient production optimization. Overall, big data analytics is revolutionizing manufacturing, driving innovation and competitiveness.

The Services segment was valued at USD 2.9 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

North America is estimated to contribute 50% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

See How Big Data In Manufacturing Market Demand is Rising in North America Request Free Sample

The market in North America is experiencing significant growth due to the region's emphasis on innovation and technology adoption. With the US and Canada being major players in manufacturing, the implementation of big data technologies and analytics is crucial for remaining competitive. Big data analytics facilitate modernization of operations, optimize supply chains, and enhance overall efficiency. In North America, manufacturing processes generate massive data from IoT sensors, machinery, and production lines. This data offers invaluable insights for optimization, leading to operational efficiency gains and cost reductions. These figures underscore the market's potential and the importance of big data analytics in the manufacturing sector.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

In the dynamic world of manufacturing, the integration of IoT sensor data has revolutionized operations, leading the towards a more data-driven and efficient future. This transformation is marked by predictive maintenance using machine learning algorithms, which enable manufacturers to anticipate equipment failures and schedule maintenance accordingly. Real-time data analytics manufacturing processes allow for swift response to production anomalies, ensuring optimal performance and minimal downtime. Supply chain optimization using big data is another significant trend, with real-time insights into inventory levels, shipping statuses, and demand patterns enabling manufacturers to streamline their operations and reduce lead times. Quality control is enhanced through the use of computer vision systems and deep learning algorithms, which can detect defects with unparalleled accuracy. Anomaly detection in manufacturing processes is crucial for maintaining optimal performance, with AI-powered systems continuously monitoring and alerting operators to potential issues. Cloud-based data analytics manufacturing solutions offer scalability and flexibility, while edge computing provides real-time insights for automated process control. Data security for sensitive manufacturing data is paramount, with advanced encryption and access control measures ensuring confidentiality. Time series forecasting for production planning and process simulation for improved efficiency are essential components of a data-driven manufacturing strategy. Digital twin technology creates a virtual manufacturing environment, allowing for real-time monitoring and optimization of complex systems. Statistical process control charts and root cause analysis using data mining are invaluable tools for continuous improvement, while predictive modeling enables capacity planning and inventory management with machine learning. Demand forecasting for optimized production and resource allocation using optimization algorithms are key elements of a successful data-driven manufacturing strategy.

What are the key market drivers leading to the rise in the adoption of Big Data In Manufacturing Industry?

- The rising adoption of Industry 4.0 technologies is the primary catalyst driving market growth. Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics into manufacturing processes. This technological revolution is transforming industries by enabling real-time data analysis, predictive maintenance, and improved efficiency, leading to significant market expansion.

- In the realm of manufacturing, the advent of Industry 4.0 has led to an influx of real-time data through IoT sensors, connected machines, and smart devices. This data deluge forms the foundation for big data analytics, enabling instant insights for informed decision-making. Predictive maintenance is a significant application of big data analytics in Industry 4.0, utilizing data and machine learning to anticipate equipment failures and schedule maintenance proactively. The implementation of predictive maintenance has resulted in a reduction of downtime by approximately 30% and a decrease in maintenance costs.

- Additionally, big data analytics plays a pivotal role in ensuring regulatory compliance and enhancing overall efficiency. With the increasing adoption of Industry 4.0 initiatives, the significance of big data analytics in manufacturing continues to grow.

What are the market trends shaping the Big Data In Manufacturing Industry?

- The emergence of artificial intelligence (AI) and machine learning (ML) represents a significant market trend. Both AI and ML technologies are gaining increasing prominence in various industries.

- AI and machine learning (ML) technologies are revolutionizing the manufacturing industry by enabling predictive maintenance, improving product quality, and optimizing operations. Predictive maintenance using AI algorithms analyzing historical equipment data reduces downtime by an average of 30%, lowers maintenance costs, and extends equipment lifespan. Real-time image recognition and ML algorithms identify defects and anomalies during production, enhancing product quality and minimizing waste.

- ML models analyze vast manufacturing datasets to identify optimization opportunities, leading to streamlined operations, improved efficiency, and reduced resource consumption. AI-driven demand forecasting, inventory optimization, and route planning are now standard in supply chain management.

What challenges does the Big Data In Manufacturing Industry face during its growth?

- The complexity of big data analytics poses a significant challenge to the growth of the industry, requiring advanced technical expertise and sophisticated tools to process and derive meaningful insights from large and intricate data sets.

- Big data analytics plays a pivotal role in the manufacturing sector, enabling companies to derive valuable insights from the massive volumes of data generated in real time. The sources of this data are diverse, ranging from sensors and machinery on the factory floor to supply chain systems and external sources. Integrating and harmonizing data from these disparate sources is a complex challenge, necessitating advanced infrastructure and processing capabilities. According to recent estimates, The market is expected to reach significant growth.

- Big data analytics offers numerous benefits to manufacturers, including improved efficiency, enhanced regulatory compliance, and optimized costs. Real-time data streams from IoT devices and sensors require fast processing and analysis to extract insights quickly. By harnessing the power of big data, manufacturers can gain a competitive edge and make informed decisions to optimize their operations.

Exclusive Technavio Analysis on Customer Landscape

The big data in manufacturing market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the big data in manufacturing market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape of Big Data In Manufacturing Industry

Competitive Landscape

Companies are implementing various strategies, such as strategic alliances, big data in manufacturing market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

ABB Ltd. - The manufacturing sector leverages big data to optimize internal processes, primarily focusing on structured data and recurring cycles. This data-driven approach enhances operational efficiency and productivity, enabling companies to remain competitive in the global market.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABB Ltd.

- Alteryx Inc.

- Cisco Systems Inc.

- Cloudera Inc.

- Dell Technologies Inc.

- Emerson Electric Co.

- Fujitsu Ltd.

- Hewlett Packard Enterprise Co.

- Hitachi Ltd.

- International Business Machines Corp.

- Oracle Corp.

- PTC Inc.

- Rockwell Automation Inc.

- Salesforce Inc.

- SAP SE

- SAS Institute Inc.

- Siemens AG

- Splunk Inc.

- Teradata Corp.

- Zensar Technologies Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Big Data In Manufacturing Market

- In January 2024, Siemens AG and Microsoft Corporation announced a strategic partnership to integrate Microsoft Azure and Siemens' MindSphere industrial IoT platform, aiming to provide advanced analytics capabilities to manufacturing industries (Microsoft Press Release, 2024).

- In March 2024, IBM announced the acquisition of Watsonx, a leading AI and machine learning company, to strengthen its position in the Big Data analytics market and enhance its offerings for manufacturing industries (IBM Press Release, 2024).

- In May 2024, General Electric (GE) and PwC formed a strategic alliance to help industrial clients implement and optimize their Big Data analytics initiatives, combining GE's Predix platform with PwC's industry expertise (GE Press Release, 2024).

- In August 2024, SAS Institute, a leading analytics software provider, announced a significant investment of USD100 million in its R&D efforts to expand its Big Data analytics capabilities for manufacturing industries (SAS Institute Press Release, 2024).

- These developments demonstrate the increasing focus of technology giants and industry leaders on collaborations, acquisitions, and investments to strengthen their Big Data analytics offerings and cater to the growing demands of the manufacturing sector.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Big Data In Manufacturing Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

225 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 26.4% |

|

Market growth 2025-2029 |

USD 21444.1 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

21.8 |

|

Key countries |

US, Canada, China, Mexico, Germany, Japan, UK, India, France, and South Korea |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

Research Analyst Overview

- The big data market in manufacturing continues to evolve, driven by the increasing adoption of advanced technologies and the need for greater efficiency and productivity. Defect detection algorithms, for instance, are becoming more sophisticated, enabling manufacturers to identify and address issues in real-time, reducing waste and improving product quality. Data visualization dashboards provide valuable insights into production processes, allowing for statistical process control and process simulation. Automated process control and supply chain analytics are also gaining traction, with anomaly detection systems helping to identify and address potential disruptions before they become major problems. Digital twin technology is revolutionizing manufacturing by allowing for real-time monitoring and optimization of production processes, while energy efficiency monitoring and product traceability systems enhance sustainability and transparency.

- Resource allocation algorithms and supply chain optimization are key areas of focus for manufacturers seeking to minimize costs and maximize efficiency. Cloud computing platforms and data integration pipelines facilitate the collection and analysis of vast amounts of data, while edge computing devices enable real-time processing and decision-making. Smart factory automation, machine learning models, and manufacturing execution systems are transforming production processes, enabling greater flexibility and responsiveness to changing market demands. Real-time data streams and product lifecycle management enable continuous improvement and optimization, while quality control metrics and production optimization ensure consistent output. Inventory management systems and time series forecasting help manufacturers to better manage their stock levels and anticipate demand, reducing waste and improving customer satisfaction.

- Waste reduction strategies and demand forecasting methods are also essential components of sustainable manufacturing practices, which are increasingly important in today's market. According to recent industry reports, the global manufacturing market is expected to grow by over 5% annually in the coming years, driven by these and other technological advancements. For example, a leading automotive manufacturer implemented a predictive maintenance system using machine learning models and IoT sensors, resulting in a 20% reduction in downtime and a 15% increase in production efficiency. This illustrates the significant impact that data-driven technologies can have on manufacturing operations.

What are the Key Data Covered in this Big Data In Manufacturing Market Research and Growth Report?

-

What is the expected growth of the Big Data In Manufacturing Market between 2025 and 2029?

-

USD 21.44 billion, at a CAGR of 26.4%

-

-

What segmentation does the market report cover?

-

The report is segmented by Type (Services and Solutions), Deployment (On-premises, Cloud-based, and Hybrid), Application (Operational analytics, Production management, Customer analytics, Supply chain management, and Others), and Geography (North America, APAC, Europe, South America, and Middle East and Africa)

-

-

Which regions are analyzed in the report?

-

North America, APAC, Europe, South America, and Middle East and Africa

-

-

What are the key growth drivers and market challenges?

-

Rising adoption of industry 4.0, Complexity of big data analytics

-

-

Who are the major players in the Big Data In Manufacturing Market?

-

ABB Ltd., Alteryx Inc., Cisco Systems Inc., Cloudera Inc., Dell Technologies Inc., Emerson Electric Co., Fujitsu Ltd., Hewlett Packard Enterprise Co., Hitachi Ltd., International Business Machines Corp., Oracle Corp., PTC Inc., Rockwell Automation Inc., Salesforce Inc., SAP SE, SAS Institute Inc., Siemens AG, Splunk Inc., Teradata Corp., and Zensar Technologies Inc.

-

Market Research Insights

- The market for big data in manufacturing is a continually evolving landscape, driven by the increasing adoption of advanced data analytics and processing technologies. According to recent industry reports, over 75% of manufacturing companies are currently investing in big data and analytics, with expectations for this figure to reach 90% within the next five years. One notable example of the impact of big data on manufacturing comes from the automotive industry. By implementing predictive maintenance strategies based on real-time analytics, a leading automaker was able to reduce unscheduled downtime by 20%, resulting in significant cost savings and improved production efficiency.

- Moreover, the market for big data in manufacturing is projected to grow at a steady pace, with some estimates suggesting a compound annual growth rate of around 20%. This growth is being fueled by the increasing availability of data from various sources, including sensors, machines, and supply chains, as well as advancements in data processing and analytics technologies. Despite these trends, challenges remain, including data preprocessing methods, data lake architectures, and the need for real-time analytics to optimize manufacturing processes. However, with ongoing innovations in areas such as machine learning, deep learning, and natural language processing, manufacturers are well-positioned to overcome these challenges and unlock the full potential of big data to drive operational excellence and business growth.

We can help! Our analysts can customize this big data in manufacturing market research report to meet your requirements.