Turbine Control System Market Size 2024-2028

The turbine control system market size is forecast to increase by USD 3.01 billion at a CAGR of 3.2% between 2023 and 2028. The market is experiencing significant growth due to the increasing demand for enhanced safety and efficiency in energy generation. Human errors and safety concerns have led to the adoption of advanced control systems that minimize the risk of accidents and improve overall performance. These systems utilize sensors and actuators to monitor and regulate turbine operations in real-time. Universal monitoring and control systems are a key trend in the market, enabling cross-company compatibility and streamlined maintenance processes. Conditional Monitoring Systems (CMS) with advanced prognostics are also gaining popularity, as they allow for predictive maintenance and early fault detection. However, there are limitations to using operational data for reliable wind turbine condition monitoring, which presents a challenge for market growth. The integration of advanced software solutions and continuous innovation in sensor technology will be crucial in addressing this challenge and driving market expansion.

Market Analysis

The market encompasses a wide range of applications, including power generation from gas turbines, steam turbines, hydro turbines, wind turbines, and gas engine installations. These control systems play a crucial role in optimizing the performance of turbines by managing parameters such as temperature, pressure, flow, and speed. In the oil and gas industry, turbine control systems are essential for efficient power generation. These systems ensure the safe and reliable operation of gas turbines by monitoring and controlling critical parameters to maintain optimal performance. Steam turbines are widely used in power generation and refrigeration applications.

Moreover, turbine control systems enable the efficient and reliable operation of steam turbines by managing steam pressure, temperature, and flow. Hydro turbines are a significant contributor to renewable energy generation. Turbine control systems for hydro turbines ensure the efficient harnessing of hydroelectric power by managing water flow and turbine speed. The wind energy sector is growing rapidly, with onshore wind capacity expanding significantly. Turbine control systems for wind turbines optimize energy production by managing wind speed, temperature, and pressure. Turbine control systems are also crucial in the aerospace industry for managing the performance of gas turbines used in aircraft engines.

Moreover, the integration of the Internet of Things (IoT) in turbine control systems offers numerous benefits, including real-time monitoring, predictive maintenance, and improved efficiency. Turbine control systems play a vital role in the international renewable energy sector, particularly in wind energy. Companies are investing in wind energy projects, including the Coastal Virginia Offshore Wind Commercial Project. Turbine control systems enable emission monitoring, ensuring compliance with environmental regulations and reducing the carbon footprint of power generation. These systems optimize turbine performance by managing critical parameters and offer significant benefits through the integration of IoT technology.

Market Segmentation

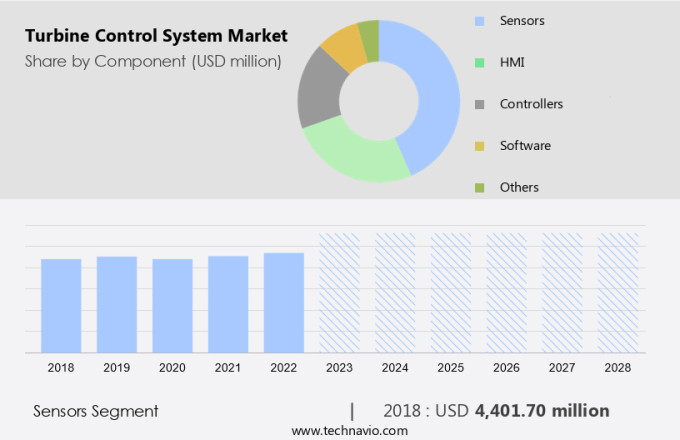

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Component

- Sensors

- HMI

- Controllers

- Software

- Others

- Type

- Gas turbine control system

- Wind turbine control system

- Steam turbine control system

- Hydro turbine control system

- Geography

- APAC

- China

- India

- North America

- US

- Europe

- Germany

- UK

- South America

- Middle East and Africa

- APAC

By Component Insights

The sensors segment is estimated to witness significant growth during the forecast period. Turbine control systems play a crucial role in ensuring the safe and efficient operation of various power generation plants, including conventional power and thermal power plants, hydro power plants, and offshore wind power. These systems utilize sensors to monitor critical parameters such as temperature, pressure, vibration, and flow within turbines. The sensor segment in The market has witnessed significant growth due to the increasing demand for reliable and efficient energy generation.

For instance, temperature sensors enable accurate monitoring of turbine temperatures to prevent overheating, while vibration sensors help detect potential mechanical issues. Pressure sensors play a vital role in maintaining optimal operational conditions. Furthermore, the integration of advanced technologies like Internet of Things (IoT) and artificial intelligence (AI) capabilities into turbine control systems is driving their adoption in power plant construction projects worldwide.

Get a glance at the market share of various segments Request Free Sample

The sensors segment accounted for USD 4.40 billion in 2018 and showed a gradual increase during the forecast period.

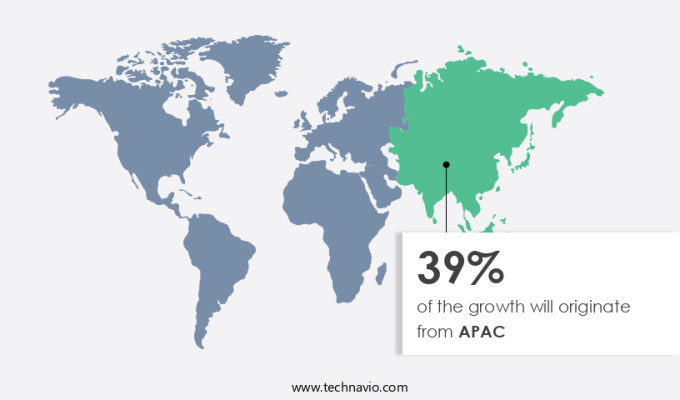

Regional Insights

APAC is estimated to contribute 39% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

The market in APAC has witnessed significant growth due to the increasing number of renewable energy projects and the growing power demand worldwide. Key countries, including Japan, China, and India, have become major contributors to this sector. For instance, China's investment in wind energy projects has led to a substantial increase in the demand for turbine control systems to enhance energy efficiency. In India, the focus on renewable energy and the implementation of smart grid technologies have contributed to market expansion. Furthermore, Japan's shift towards greener energy sources following the Fukushima disaster has accelerated the adoption of turbine control systems in the country's power generation industry.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Market Driver

Universal turbine monitoring and control systems enable cross-vendor compatibility is the key driver of the market. In the oil and gas industry, the control systems market for temperature, pressure, flow, and speed in power generation applications is witnessing significant advancements. As the original equipment manufacturer for these turbines, Emerson ensures compatibility and seamless integration.

These systems offer interchangeable hardware, portable software, and upgradable technology, enabling supplier independence and cross-company compatibility. With both companies providing global support, technology upgrades, and standardization, the market for turbine control systems in power generation continues to evolve, offering increased efficiency and reliability.

Market Trends

Conditional Monitoring Systems (CMS) with advanced prognostics is the upcoming trend in the market. The market has undergone significant transformation in the realm of condition monitoring systems and data acquisition. With the rising demand for cost-effective, high-performance systems, there has been a wave in the installation of advanced condition monitoring systems (CMS) featuring predictive analytics.

CMS utilizes cloud computing to house intricate mathematical algorithms instead of relying on costly sensors and electronics. This setup enables wind farms to transmit data from every turbine sensor for centralized processing. The implementation of CMS with predictive analytics offers numerous advantages and reduced expenses on sensor equipment. Enhanced safety by minimizing human errors. Improved system performance through real-time monitoring and analysis.

Market Challenge

Limitations in using operational data for reliable wind turbine condition monitoring is a key challenge affecting the market growth. The market encompasses the use of advanced automation technologies in Refrigeration, Aerospace, and Marine industries for optimizing the efficiency of wind turbines. The system's primary function is to monitor and control the operational parameters of wind turbines, including wind speed, direction, yaw angle, pitch angle, active power, reactive power, generator current, generator speed, gearbox temperature, generator winding temperature, and ambient temperature. Operational data from wind turbines is collected by Supervisory Control and Data Acquisition (SCADA) systems for performance analysis and health assessment.

However, the data collected can be influenced by various factors, leading to inconsistencies and unreliability. Comparing operational parameters over time and at different levels can reveal significant changes in system behavior, impacting the overall performance and efficiency. Automation in Turbine Control Systems helps reduce operating costs by minimizing downtime, optimizing energy production, and improving maintenance scheduling. The integration of these systems with other advanced technologies such as Artificial Intelligence and Machine Learning can further enhance their capabilities, enabling predictive maintenance and real-time performance analysis.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Siemens AG: The company offers SPPA R3000 Turbine Controls.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ABB Ltd.

- American Superconductor Corp.

- Baker Hughes Co.

- Compressor Controls Corp.

- Emerson Electric Co.

- General Electric Co.

- Heinzmann GmbH and Co. KG

- Honeywell International Inc.

- HPI Energy Services LLC

- Innoway Future Solutions Pte Ltd.

- Kawasaki Heavy Industries Ltd.

- Mitsubishi Heavy Industries Ltd.

- Proeon Systems Ltd.

- Robert Bosch GmbH

- Rockwell Automation Inc.

- Rolls Royce Holdings Plc

- Solar Turbines Inc.

- Vestas Wind Systems AS

- Woodward Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Turbine control systems play a crucial role in optimizing the performance and efficiency of various types of turbines, including gas, steam, hydro, wind, and gas engine installations, in power generation and other industries. These systems monitor and control parameters such as temperature, pressure, flow, and speed to ensure safe and reliable operation. In the oil and gas sector, turbine control systems are essential for powering refineries and reducing operating costs. In the aerospace and marine industries, they ensure safety and efficiency in turbine-powered engines. Automation of turbine control systems has led to significant improvements in efficiency and reduced human errors.

Furthermore, sensors and actuators are integrated into these systems to provide real-time data and enable quick response to changing conditions. Software solutions enable remote monitoring and analysis of turbine performance, while IoT-based turbine systems offer advanced capabilities for predictive maintenance and emission monitoring. Turbine control systems are used extensively in conventional power plants, thermal power plants, hydro power plants, offshore wind power, and power plant construction. They are also critical for wind energy applications, with onshore wind capacity continuing to grow rapidly. Regardless of the application, turbine control systems are essential for ensuring optimal performance, reducing operating costs, and maintaining safety and reliability.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

193 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.2% |

|

Market Growth 2024-2028 |

USD 3.01 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

3.06 |

|

Regional analysis |

APAC, North America, Europe, South America, and Middle East and Africa |

|

Performing market contribution |

APAC at 39% |

|

Key countries |

China, US, Germany, India, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

ABB Ltd., American Superconductor Corp., Baker Hughes Co., Compressor Controls Corp., Emerson Electric Co., General Electric Co., Heinzmann GmbH and Co. KG, Honeywell International Inc., HPI Energy Services LLC, Innoway Future Solutions Pte Ltd., Kawasaki Heavy Industries Ltd., Mitsubishi Heavy Industries Ltd., Proeon Systems Ltd., Robert Bosch GmbH, Rockwell Automation Inc., Rolls Royce Holdings Plc, Siemens AG, Solar Turbines Inc., Vestas Wind Systems AS, and Woodward Inc. |

|

Market dynamics |

Parent market analysis, market growth inducers and obstacles, market forecast, fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, market condition analysis for the forecast period |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch