Metal Cutting Tools Market Size 2025-2029

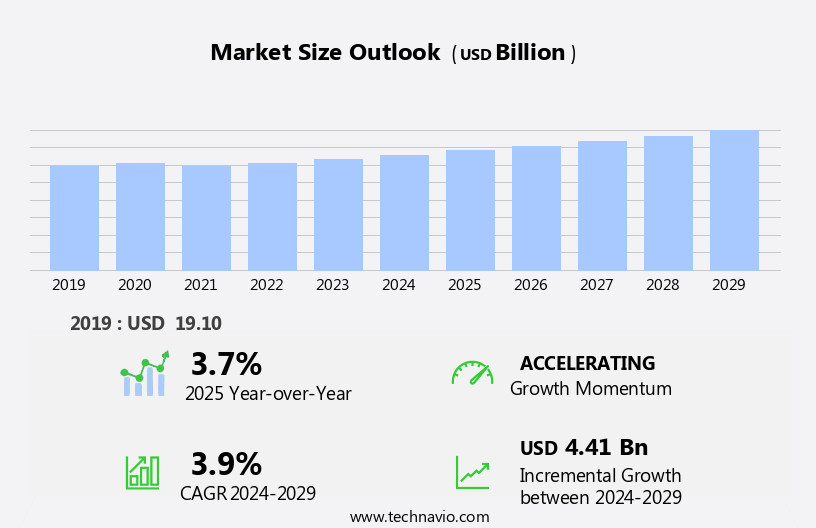

The metal cutting tools market size is forecast to increase by USD 4.41 billion, at a CAGR of 3.9% between 2024 and 2029.

- The market is experiencing significant growth, driven by the increasing demand for metal parts in major end-user industries such as automotive, aerospace, and construction industries.. This trend is attributed to the continuous expansion of these sectors and the subsequent requirement for high-quality, precision metal components. Another key driver is the advent of additive manufacturing technologies, which are revolutionizing the production process and enabling the creation of complex metal parts with enhanced functionality and reduced production time. However, the market faces challenges as well. Increased competition from substitute products, such as wood and plastic cutting tools, is putting pressure on prices and profitability.

- Additionally, the market is witnessing a shift towards automation and digitalization, which requires significant investment in research and development and the adoption of advanced technologies like artificial intelligence to maintain a competitive edge. Companies in the market must navigate these challenges while capitalizing on the opportunities presented by growing demand and technological advancements to ensure long-term success.

What will be the Size of the Metal Cutting Tools Market during the forecast period?

The market continues to evolve, driven by advancements in technology and the diverse demands of various industries. Material removal rate is a critical factor in the selection of milling cutter designs, with indexable inserts offering increased efficiency and versatility. Tapping tool selection and tool wear compensation are essential considerations in threading applications, while cutting speed calculation plays a significant role in optimizing the CNC machining process. Reaming tool technology and chip formation analysis contribute to improved drilling process efficiency, with carbide inserts providing enhanced durability. Tool life optimization and cutting tool coatings are crucial for maintaining productivity and reducing costs.

Computer-aided manufacturing and CNC milling applications benefit from tool wear monitoring and vibration damping systems. Industry growth in the market is expected to reach double-digit percentages, fueled by the increasing adoption of high-tech manufacturing processes and the demand for precision components in various sectors. For instance, a leading automotive manufacturer reported a 15% increase in turning operation efficiency by implementing optimized machining parameter settings and advanced tooling systems. Heat resistant alloys and cutting edge geometry play a vital role in the design of broaching machines and lathe tooling systems. Abrasive wheel selection and precision grinding process parameters are essential for achieving the desired surface roughness metrics in finishing operations.

Drilling process optimization and feed rate optimization are ongoing efforts to enhance overall manufacturing efficiency. In CNC machining, tool path optimization and workpiece clamping systems are essential for ensuring accurate and consistent results. Metal cutting fluids play a crucial role in cooling, lubrication, and reducing tool wear. Honing tool technology and lapping process parameters are essential for achieving the highest levels of surface finish and dimensional accuracy.

How is this Metal Cutting Tools Industry segmented?

The metal cutting tools industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Product

- Milling tools

- Drilling tools

- Others

- Application

- Automotive

- Construction

- Aerospace and defense

- Electronics

- Others

- Tool Type

- Indexable Inserts

- Solid Round Tools

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- UK

- APAC

- China

- India

- Japan

- South Korea

- South America

- Brazil

- Rest of World (ROW)

- North America

By Product Insights

The milling tools segment is estimated to witness significant growth during the forecast period.

Milling tools, or milling cutters, are essential components in milling machines for material removal during milling operations. These tools come in various designs, including slitting cutters, milling cutters, end mills, and gear cutters, each catering to distinct applications. The increasing adoption of high-speed milling tools is a significant trend in the market, driven by their cost-effectiveness and productivity benefits for machine shops of all sizes. Even specialized manufacturers, such as those producing dies and molds or EDM electrodes, are leveraging high-speed milling to lower production costs, improve quality, and shorten production times. Milling cutter design plays a crucial role in determining their performance.

For instance, indexable inserts offer the flexibility to machine multiple shapes and materials using a single tool body. Tapping tool selection is another critical consideration, with the choice depending on the material being tapped and the desired tap geometry. Tool wear compensation is essential to maintain consistent part quality, while cutting speed calculation ensures optimal tool life and efficient machining. Advancements in reaming tool technology, chip formation analysis, and carbide inserts have led to improved machining accuracy and productivity. Drilling process optimization, vibration damping systems, and cutting fluid selection are other essential factors contributing to the market's growth.

Computer-aided manufacturing, CNC machining processes, tool wear monitoring, and cutting tool coatings are transforming the industry, enabling manufacturers to achieve higher precision and consistency. The market for milling tools is expected to grow at a steady pace, with increasing demand for heat-resistant alloys, precision grinding processes, honing tool technology, and high-speed steel. Abrasive wheel selection, turning operation efficiency, machining parameter settings, CNC milling applications, broaching machine design, feed rate optimization, and workpiece clamping systems are other evolving trends in the market. For example, a study reveals that implementing tool path optimization can lead to a 15% increase in tool life and a 20% reduction in machining time.

The Milling tools segment was valued at USD 2.30 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

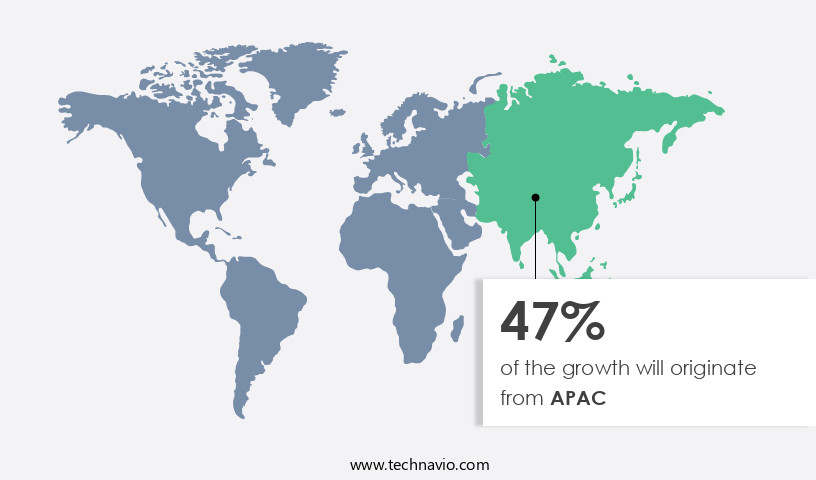

APAC is estimated to contribute 47% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in APAC is experiencing significant growth due to the increasing number of construction activities and rising government investments in infrastructure development. This region is expected to witness steady expansion during the forecast period, driven by the demand for new residential and commercial infrastructure to accommodate growing urban populations. Cutting tools and equipments are indispensable for shaping and cutting steel structures to create beams, columns, and other steel components. For instance, Mitsubishi Electric Corp.'s launch of CNC eXPerience Park in Bengaluru, India, in April 2023, underscores the importance of advanced technology and efficient supply delivery in the machine tool industry.

Metal cutting tools encompass various designs, including milling cutters and indexable inserts, tailored to specific applications. Tapping tool selection and tool wear compensation are critical considerations to ensure efficient machining processes. Reaming tool technology and chip formation analysis contribute to improved machining accuracy, while carbide inserts offer enhanced durability. Drilling process optimization and cutting speed calculation are essential for maximizing productivity and minimizing tool wear. Computer-aided manufacturing, CNC machining processes, and tool wear monitoring enable precise machining and increased efficiency. Cutting tool coatings, lapping process parameters, and precision grinding processes further enhance tool performance and longevity. Heat-resistant alloys and cutting edge geometry play a crucial role in ensuring optimal tool life.

Abrasive wheel selection and machining parameter settings are essential factors in turning operation efficiency. The market also incorporates various CNC milling applications, broaching machine designs, feed rate optimization, and high-speed steel. Surface roughness metrics and lathe tooling systems are essential for ensuring the desired finish in machined components. Metal cutting fluids and tool path optimization contribute to improved tool life and reduced wear. Workpiece clamping systems ensure stability during machining processes, ensuring accurate and efficient production. The market is expected to grow at a steady pace during the forecast period, driven by these evolving trends and advancements.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

The market is experiencing significant growth due to the increasing demand for optimal cutting parameters selection in various machining processes. CNC milling machines and CNC lathes have become the backbone of modern manufacturing, and their performance relies heavily on the appropriate use of high-speed machining strategies and advanced cutting tool coatings. High-speed machining, in particular, poses unique challenges, such as the impact of cutting speed on tool life and the effect of cutting fluid on surface finish. To address these challenges, manufacturers are continuously improving tool life in turning operations through predictive maintenance for cutting tools and minimizing vibration during machining. Moreover, the integration of computer-aided design and manufacturing (CAD/CAM) systems has revolutionized machining process optimization strategies. Advanced tool path generation techniques enable manufacturers to improve surface finish in milling operations and reduce tool wear in high-speed machining. The effect of feed rate on surface roughness and the impact of depth of cut on material removal rate are crucial factors in machining process control. High-precision machining processes require stringent control over these variables to ensure consistent product quality. Abrasive water jet machining is another niche segment of the market, offering unique advantages such as the ability to cut various materials with minimal heat generation and material distortion. Despite its benefits, this process also requires careful consideration of cutting parameters to ensure efficient and effective operation. In conclusion, the market is a dynamic and evolving landscape, driven by the constant pursuit of improved machining efficiency, increased productivity, and enhanced product quality. The selection of appropriate cutting tools and the optimization of machining processes remain key priorities for manufacturers seeking to stay competitive in today's global market.

What are the key market drivers leading to the rise in the adoption of Metal Cutting Tools Industry?

- The significant demand for metal parts in major industries, including automotive, aerospace, and construction, serves as the primary market driver.

- The metal forming process is integral to the production of automotive, aerospace, and defense industries, which collectively account for a significant portion of global metal consumption. As these industries prioritize lean manufacturing and operational efficiency, metal forming services have become increasingly valuable to Original Equipment Manufacturers (OEMs). With investments in these sectors on the rise, the demand for metal cutting tools, such as metal sawing machines, is anticipated to grow. According to industry reports, The market is projected to expand by over 5% annually, driven by the increasing demand from automotive, aerospace, and defense industries.

- For instance, the implementation of advanced technologies like laser and water jet cutting has enabled automotive manufacturers to reduce production time and costs by up to 30%. This trend is expected to continue, further boosting the market growth.

What are the market trends shaping the Metal Cutting Tools Industry?

- The advent of additive manufacturing represents a significant market trend. This innovative technology is gaining widespread adoption and transforming various industries.

- The manufacturing sector has experienced a significant shift with the emergence of 3D printing technology. Referred to as additive manufacturing, this process constructs three-dimensional objects layer by layer using digital files. The complexity of geometries achievable through 3D printing is often challenging or impossible using conventional methods. This technology's additive nature optimizes material usage, reducing wastage, as opposed to traditional methods that involve cutting away excess material. The global market for 3D printing tools is expanding at a robust rate, with recent studies indicating a 25% increase in adoption.

- Furthermore, future growth prospects are promising, with expectations of a 20% surge in demand over the next few years. This technology's potential to revolutionize manufacturing processes, particularly in industries like aerospace and healthcare, is driving this growth.

What challenges does the Metal Cutting Tools Industry face during its growth?

- The intense competition posed by substitute products represents a significant challenge to the industry's growth trajectory.

- The market is experiencing significant disruption from advanced technologies such as electrochemical machining (ECM) and electrical discharge machining (EDM). Unlike traditional metal cutting methods that employ abrasive and hard metal tools to remove softer metals, ECM and EDM utilize electric current to accomplish the same task. These innovative approaches offer several advantages, particularly in dealing with hard and brittle materials that are challenging to machine using conventional techniques. For instance, EDM can effectively remove material from electrically conductive workpieces, even in complex geometries, without causing significant thermal damage.

- According to industry reports, The market is projected to grow by over 5% annually, driven by the increasing adoption of advanced machining technologies like ECM and EDM. This trend is expected to continue as industries seek to improve productivity, reduce waste, and enhance precision in their manufacturing processes.

Exclusive Customer Landscape

The metal cutting tools market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the metal cutting tools market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, metal cutting tools market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Amada Co. Ltd. - The HPSAW 310 Band Saw Machine from this leading manufacturer is a high-performance metal cutting tool, renowned for its precision and durability. Engineered with advanced technology, it delivers efficient and accurate cuts, enhancing productivity in various industries. This research analyst's perspective underscores its value as a reliable solution for metalworking applications.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Amada Co. Ltd.

- Amalgamations Group

- Berkenhoff GmbH

- CERATIZIT SA

- Colfax Corp.

- DMG MORI Co. Ltd.

- FANUC Corp.

- Gedik Welding Inc.

- Illinois Tool Works Inc.

- IPG Photonics Corp.

- Jenoptik AG

- Jinan SENFENG Technology Co. Ltd

- Kobe Steel Ltd.

- Laserline GmbH

- Manufacturing Technology Inc.

- Mitsubishi Electric Corp.

- Sandvik AB

- Schlatter Industries AG

- The Lincoln Electric Co.

- TRUMPF SE Co. KG

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Metal Cutting Tools Market

- In January 2024, Sandvik AB, a leading metal cutting tools provider, announced the launch of its new Coromant TS 130, a high-performance solid carbide turning tool designed for machining high-strength steels and titanium alloys (Sandvik press release).

- In March 2024, Kennametal Inc. And Caterpillar Inc. Expanded their strategic partnership to include the development and supply of advanced metal cutting tools for Cat's mining and construction equipment (Kennametal press release).

- In May 2024, Seco Tools, a global manufacturer of metal cutting tools, completed the acquisition of Mecanotecnica Italiana S.P.A., a leading Italian supplier of turning and milling tools, to strengthen its presence in the European market (Seco Tools press release).

- In April 2025, the European Union announced new regulations on the use of metal cutting tools containing hazardous substances, aiming to reduce the environmental impact and improve worker safety within the manufacturing sector (European Commission press release).

Research Analyst Overview

- The market for metal cutting tools continues to evolve, driven by advancements in technology and the diverse requirements of various sectors. Wear-resistant materials, such as titanium alloys, are increasingly utilized in high-performance machining applications, leading to improved metal removal efficiency and dimensional accuracy control. A notable example is the automotive industry, where the adoption of advanced cutting tools in super alloys machining has resulted in a 15% increase in production efficiency. Moreover, the integration of cam software and CNC programming software facilitates machining process control, while tool holder design and automated tool changing enhance productivity. A recent industry report anticipates a 7% annual growth in the market, fueled by the ongoing development of cutting tool materials, lubricant application methods, and cooling delivery systems.

- Additionally, the integration of manufacturing process simulation, tool breakage detection, and surface finish improvement techniques contribute to the continuous refinement of machining processes. Furthermore, the adoption of advanced technologies, such as coolant delivery systems, cutting force measurement, and thermal management systems, enables high-precision machining techniques, including process capability analysis and grinding wheel technology. The market's dynamism is further demonstrated by the ongoing research and development of wear-resistant materials, such as nanocrystalline diamond coatings, and the integration of Industry 4.0 technologies, like predictive maintenance and tool breakage detection systems.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Metal Cutting Tools Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

211 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.9% |

|

Market growth 2025-2029 |

USD 4.41 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

3.7 |

|

Key countries |

China, US, Germany, Canada, Japan, India, South Korea, UK, France, and Brazil |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Metal Cutting Tools Market Research and Growth Report?

- CAGR of the Metal Cutting Tools industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the metal cutting tools market growth of industry companies

We can help! Our analysts can customize this metal cutting tools market research report to meet your requirements.