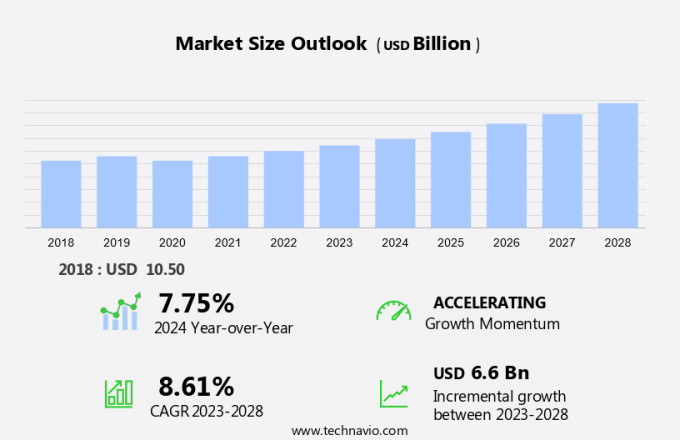

Shape Memory Materials Market Size 2024-2028

The shape memory materials market size is forecast to increase by USD 6.6 billion at a CAGR of 8.61% between 2023 and 2028. The market is experiencing significant growth due to increasing demand in various industries, particularly in cardiac treatments, automotive production, and aerospace. With an aging population and rising life expectancy, the need for advanced medical device solutions, including shape memory polymers, is on the rise. In the automotive sector, there is a growing emphasis on lightweight materials to improve fuel efficiency and reduce emissions. Shape memory alloys and polymers, with their unique shape memory effect and superelasticity, offer ideal solutions for weight reduction and design flexibility. Similarly, in the aeronautics industry, shape memory materials' viscoelasticity is being explored for applications in aircraft structures and engine components. Overall, the market's growth is driven by these trends and the potential for innovation in various sectors.

Market Analysis

Shape memory materials (SMMs), also known as memory alloys, exhibit unique properties such as superelasticity and viscoelasticity, making them an essential component in various industries. These materials can return to their original shape after being deformed, offering significant advantages in terms of functionality and durability. The global market for shape memory materials is experiencing steady growth due to their increasing application in sectors like aerospace, medical, and automotive. In the aerospace industry, SMMs are utilized for manufacturing components that require high stiffness values and the ability to withstand extreme temperatures. These materials are crucial for ensuring the safety and efficiency of aircraft and spacecraft. In the medical and healthcare sectors, shape memory materials are used extensively in medical devices, including stents, drug delivery systems, embolization devices, and wound closure systems. Their biocompatibility and ability to return to their original shape make them ideal for applications where precision and flexibility are essential.

Additionally, in the automotive sector, shape memory materials are used in various applications, such as airbag sensors, fuel lines, and engine components. Their ability to return to their original shape after deformation makes them an attractive alternative to traditional materials, offering improved safety, durability, and performance. The building and construction industry also benefits from the use of shape memory materials, particularly in textiles and fashion applications. Nitinol and other SMMs are used to create self-adjusting textiles that can change shape in response to temperature or stress, offering potential applications in clothing, upholstery, and architectural design. In summary, the market is driven by their unique properties and versatility, making them an essential component in various industries, including aerospace, medical, automotive, and building and construction.

Market Segmentation

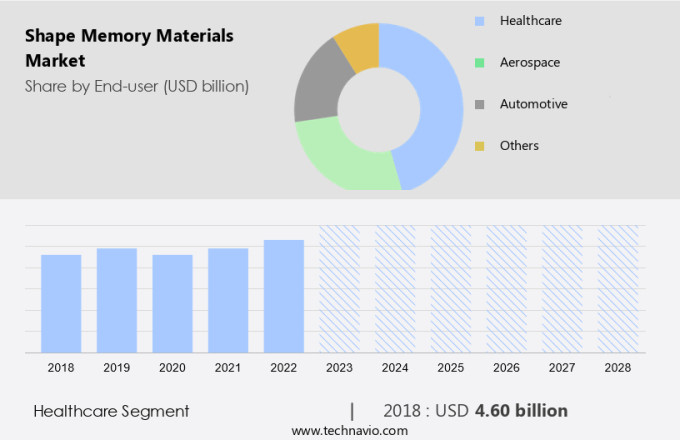

The market research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Healthcare

- Aerospace

- Automotive

- Others

- Geography

- North America

- US

- Europe

- Germany

- UK

- APAC

- China

- Japan

- Middle East and Africa

- South America

- North America

By End-user Insights

The healthcare segment is estimated to witness significant growth during the forecast period. Shape memory materials have gained significant traction in various industries due to their unique properties, including cardiac treatments. These materials, which exhibit the shape memory effect and superelasticity, are particularly beneficial for an aging population with increasing life expectancy. In the healthcare sector, shape memory polymers are utilized in the production of hospital accessories such as syringes, blood bags, catheters, and pharmaceutical containers. The compatibility of these materials with various sterilizing methods, including vaporized hydrogen peroxide, steam, gamma radiations, and ethylene oxide, is a critical factor in their selection. Solvay is a leading provider of polymer grades for various applications.

Thermoplastic, a common polymer used in manufacturing hospital accessories, is favored due to its ease of liquefaction and moldability, making it suitable for custom plastic injection molding and injection blow-molding services. Notable thermoplastic materials used in healthcare manufacturing include polycarbonate, polypropylene, and polyethylene. Beyond healthcare, shape memory materials are also employed extensively in the automotive and aeronautics industries. Their ability to return to their original shape after deformation makes them ideal for applications such as seatbelts, airbags, and fuel lines. In the automotive sector, these materials contribute to improved safety and performance, while in aeronautics, they enhance the durability and reliability of components.

Get a glance at the market share of various segments Request Free Sample

The healthcare segment accounted for USD 4.60 billion in 2018 and showed a gradual increase during the forecast period.

Regional Insights

Europe is estimated to contribute 43% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions Request Free Sample

The United States represents a significant market for shape memory materials in North America, with continued growth expected in 2023. Factors fueling this expansion include escalating healthcare expenditures, advancements in technology, and stringent regulatory requirements. The medical sector in North America presents substantial growth prospects, as innovative developments in healthcare drive the need for shape memory materials. These materials are essential in addressing the medical sector's demands, compelling manufacturers to keep abreast of technological advancements. Furthermore, the increasing awareness of health and wellness among the population has led to a rise in preventative measures, such as regular health tests and checkups, resulting in increased hospital visits and surgeries.

Thus, this heightened demand for medical devices, including those coated with shape memory materials, further bolsters market growth. The economic growth in the US, coupled with a well-established business ecosystem, creates a favorable environment for investors in this sector. However, concerns regarding the supply chain, consumer preferences, policy amendments, environmental sustainability, and geopolitical tensions may impact market dynamics. Adhering to a strong regulatory framework is crucial for market participants to maintain investment discipline and ensure long-term success.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

Market Driver

Increasing shape memory materials demand in automotive and aerospace sector is the key driver of the market. Shape memory materials have brought numerous benefits to the aerospace industry, including weight reduction, enhanced efficiency, and extended product lifespan. In this sector, epoxies serve as the primary matrix materials, while carbon or graphite, aramid, and high-stiffness glass fiber function as reinforcement materials. Polyetheretherketone (PEEK), a high-performance thermoplastic, is another material commonly utilized in the aerospace industry. The global aviation sector is experiencing substantial growth, leading to an increase in air travelers. According to the International Civil Aviation Organization, the number of passengers carried on scheduled services reached a record high of 4.3 billion in 2019. As a result, the demand for lightweight, durable, and efficient aerospace components is on the rise.

Procurement and inventory management in the aerospace industry require exceptional capabilities to ensure the timely delivery of high-quality components. Regional-specific strategies are essential to address the varying demands and regulations across different geographies. The energy transition and the shift towards bio-chemicals and sustainable materials are key trends influencing the materials market. Recovery and cost consciousness are also crucial factors driving the industry's growth. In the context of the North American market, the United States is a significant player, with major aerospace manufacturers and a large domestic market. To stay competitive, companies must continuously innovate and adapt to the evolving market landscape.

Market Trends

The need for lightweight automotive is the upcoming trend in the market. The market has witnessed significant advancements, with numerous new initiatives being introduced. One such development is a multi-year collaboration between I-Form, an SFI Research Centre for Advanced Manufacturing, and Fort Wayne Metals, a US manufacturing company. This partnership aims to explore 3D printing of wires and tubing using metal alloys for next-generation medical devices. This research could lead to innovations in medical devices such as catheters and stents. Another significant move in the market was DJO's acquisition of MedShape, Inc. In April 2021. DJO, a subsidiary of Colfax Corporation, completed this deal to expand its offerings in the medical and healthcare sector.

MedShape specializes in shape memory alloys for medical applications, including drug delivery, embolization, wound closure, and biocompatible stents. This acquisition is expected to enhance the quality of medical treatments by providing advanced shape memory materials for various medical devices.

Market Challenge

Concerns with use of smart polymers is a key challenge affecting the market growth. Shape memory materials, specifically polymers, encounter challenges in their application due to unpredictable behavior during biphasic discharge profiles. For instance, neuronal burst discharges, characterized by three or more action potentials with inter-spike intervals of less than or equal to 30 milliseconds or two spikes with intermissions of less than or equal to 15 milliseconds, pose a challenge in terms of synchronization with peak interaction in the temporal lobes. Moreover, the use of these materials in medication requires addressing concerns related to discharge kinetics, conformational integrity during handling, and ensuring biological actions remain secure during discharge. As the healthcare, administrative, and business landscapes continue to evolve, pharmaceutical, biotechnology, and medical technology companies must adapt their research and development, pricing strategies, supply chain networks, and business models to the current economic climate.

Operational efficiency remains a priority, especially during periods of economic slowdown or stagflation. Trade and logistics play a crucial role in the success of these companies, and supply chain dynamics must be carefully managed to mitigate risks and maintain profitability. In conclusion, shape memory materials, particularly polymers, offer significant potential for advancements in various industries. However, addressing challenges related to their behavior during discharge and ensuring their compatibility with biological systems is essential. Additionally, companies must remain agile in their approach to research and development, pricing, and supply chain management to navigate the evolving economic landscape.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Allegheny Technologies Inc.: The company offers ATI NiTiFe alloy that is used in shape memory nickel titanium alloy coupling devices.

The market research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- BASF SE

- Boston Centerless Inc.

- Chongqing Gearbox Co. Ltd.

- Confluent Medical Technologies

- Covestro AG

- Daido Steel Co. Ltd.

- DYNALLOY Inc

- EUROFLEX GmbH

- Fort Wayne Metals Research Products LLC

- Johnson Matthey Plc

- Metalwerks Inc.

- Nanoshel LLC

- Nippon Steel Corp.

- Precision Castparts Corp.

- SAES Getters Spa

- SMP Technologies Inc.

- Spintech Holdings Inc.

- Stanford Advanced Materials

- Ultimate Wireforms Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key market players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Shape memory materials, also known as SMMs, are a class of advanced materials that exhibit the ability to return to their original shape after being deformed or subjected to certain temperatures. These materials, which include shape memory polymers (SMPs) and metals like nitinol, are gaining significant attention in various industries due to their unique properties of superelasticity and viscoelasticity. The global market for shape memory materials is experiencing strong growth, driven by their increasing adoption in the aerospace, medical, and automotive sectors. In the medical field, SMMs are being used in medical devices such as stents, drug delivery systems, and embolization devices due to their biocompatibility and ability to recover their shape in response to body temperature. The aging population and increasing life expectancy are also fueling the demand for shape memory materials in healthcare applications.

Further, in the automotive sector, SMMs are being used for engine components, exhaust systems, and seat belts due to their ability to absorb energy and return to their original shape. The shape memory effect is also finding applications in the building and construction industry, textiles, electric vehicles, and 3D printing. However, the market is facing challenges such as supply chain concerns, economic slowdown, and regulatory frameworks. Despite these challenges, the market is expected to continue growing due to investment discipline, business ecosystems, and sustainability initiatives. The market is segmented into product segments such as shape memory alloys and polymers, and geographies such as North America, Europe, Asia-Pacific, and the Middle East and Africa. The market is expected to witness significant developments in the coming years, driven by revenue growth and price trends.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

143 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 8.61% |

|

Market growth 2024-2028 |

USD 6.6 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

7.75 |

|

Regional analysis |

North America, Europe, APAC, Middle East and Africa, and South America |

|

Performing market contribution |

Europe at 43% |

|

Key countries |

US, Japan, Germany, UK, and China |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

Allegheny Technologies Inc., BASF SE, Boston Centerless Inc., Chongqing Gearbox Co. Ltd., Confluent Medical Technologies, Covestro AG, Daido Steel Co. Ltd., DYNALLOY Inc, EUROFLEX GmbH, Fort Wayne Metals Research Products LLC, Johnson Matthey Plc, Metalwerks Inc., Nanoshel LLC, Nippon Steel Corp., Precision Castparts Corp., SAES Getters Spa, SMP Technologies Inc., Spintech Holdings Inc., Stanford Advanced Materials, and Ultimate Wireforms Inc. |

|

Market dynamics |

Parent market analysis, market growth inducers and obstacles, market forecast, fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, market condition analysis for the forecast period |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the market in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch